Feeding Solutions

Fast, reliable and versatile feeding solutions

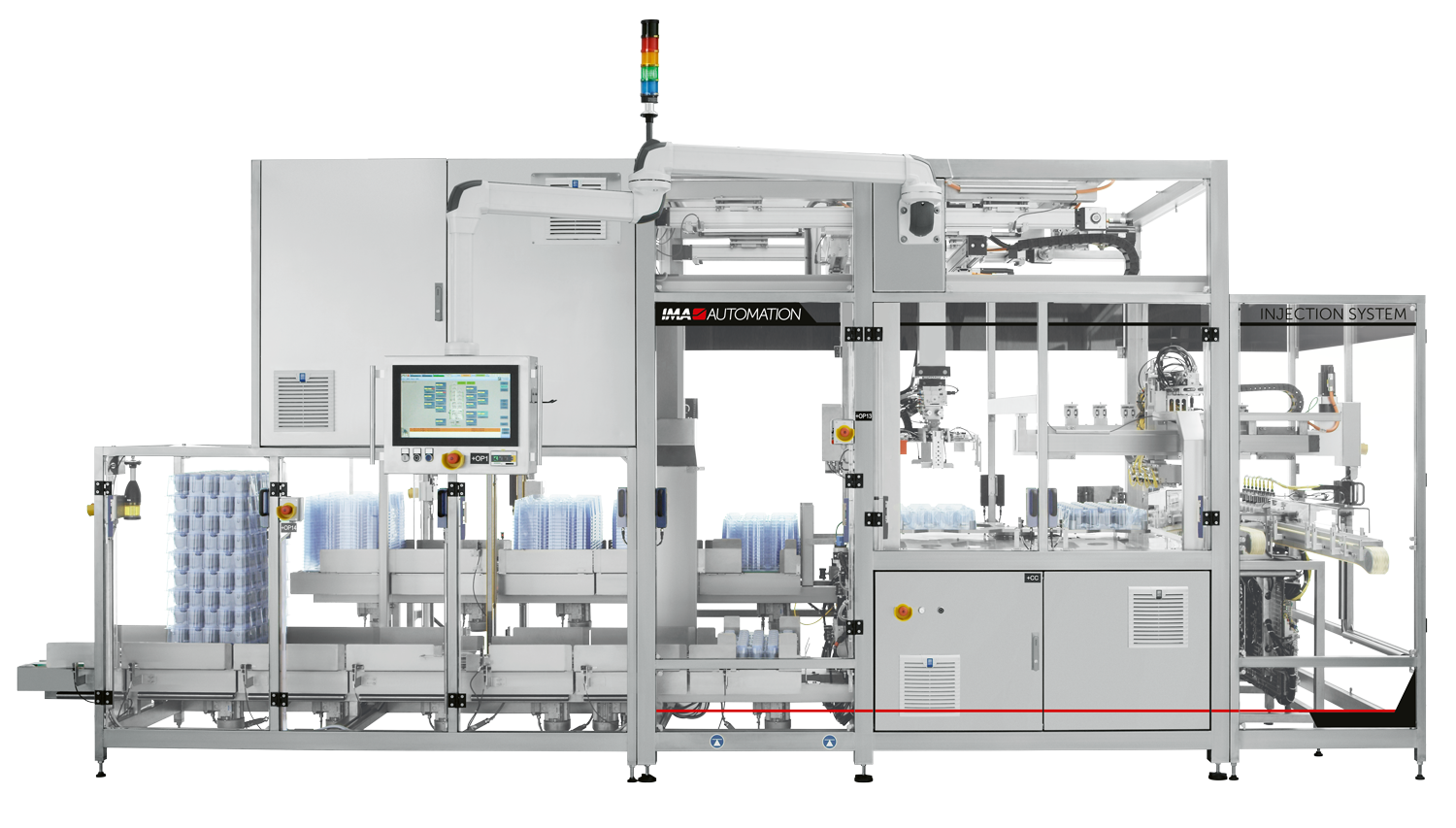

IMA MED-TECH offers cost-effective feeding systems for the conductor feeders automation industry, designed to meet key process needs such as:

- Value for money

- Layout constraints

- Ergonomics

- Maintenance accessibility

- Energy efficiency

- Noise reduction

- Ease of cleaning

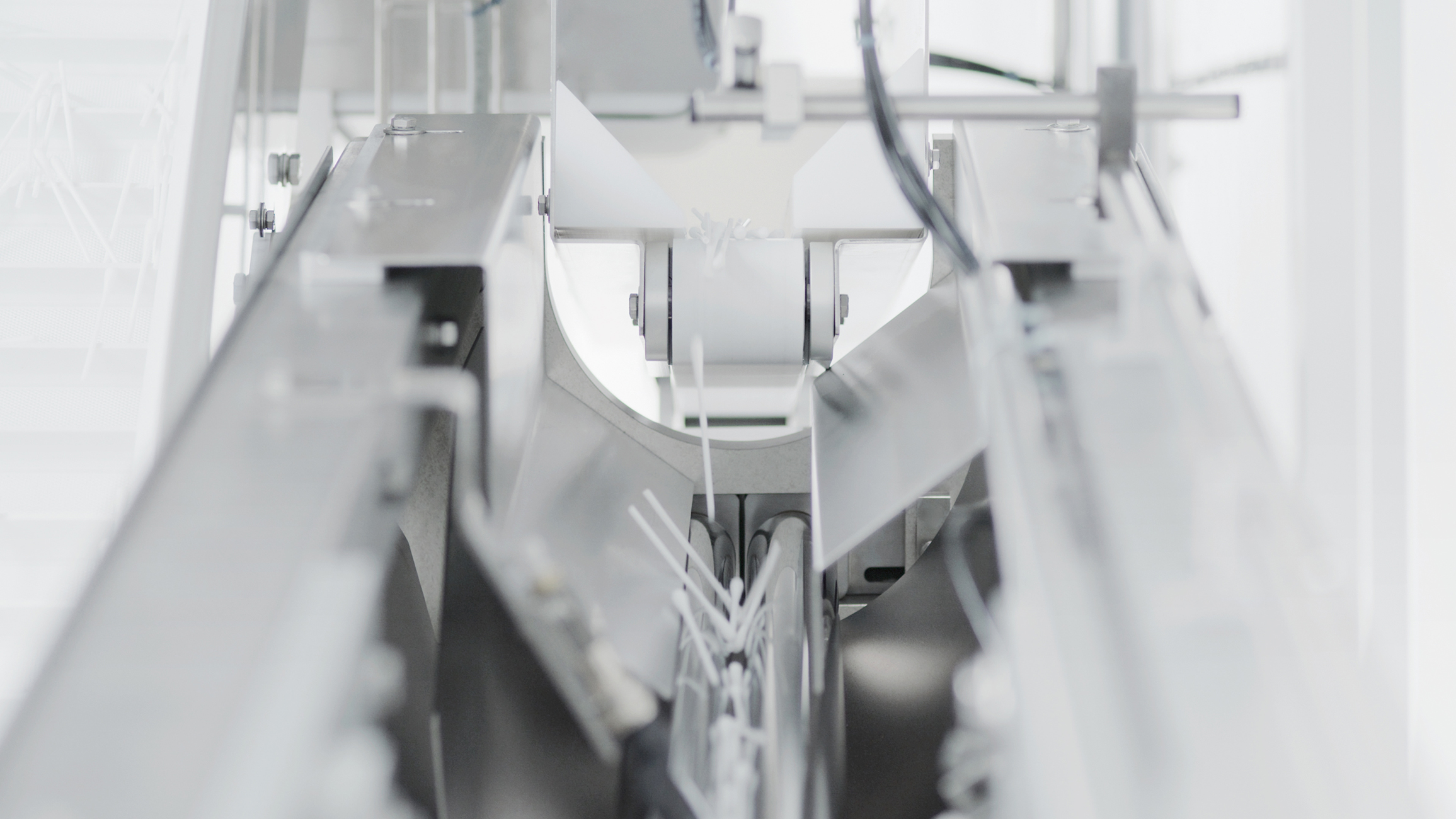

These systems automatically supply components to assembly lines, with configurations chosen based on the presentation form (bulk, tray, pallet, etc.) and specific component characteristics like geometry and surface.

Feeding systems are used to feed assembly lines with individual components. Various feeding systems and configurations are available to automatically feed all common components

The choice of the feeding system depends on how the components are presented, e.g. in bulk, tray, pallet or other form. We consider geometries, surface specifications and other critical criteria to choose the optimal feeding solution.

Tray Loaders and Palletizers

A range of tray loaders and palletizers to efficiently feed components into machines. These devices handle destacking, tray & device identification, and individual device handling with optimal autonomy.

- Tray Loaders:

For speeds between 40 and 80 ppm, compact models are available; for higher speeds (up to 300 ppm), larger tray loaders with increased storage are offered. For speeds up to 350 ppm, palletizing systems with pallet carriers or AGVs are used for fully automated processing.

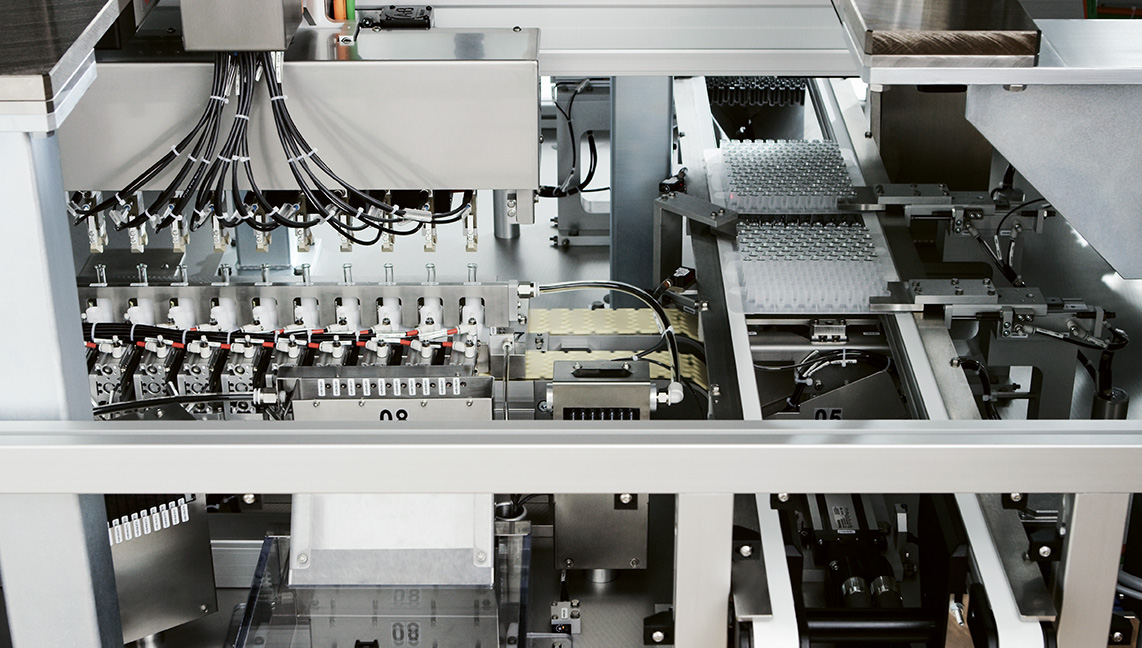

Syringe Feeding

- Speed range: 20 to 400 ppm

- No glass-to-glass or glass-to-metal contact

- PFS inspection available

Cartridge Feeding

- Speed range: 20 to 400 ppm

- Inspection and 2D Datamatrix control possible

Flexible system, ideal replacement of manual feeding in case of small batches production

- Able to handle multiple objects

- Fully automatic changeover

- Possibility to label the objects with track & trace and single label rejection before application

- Max speed: 45 ppm

But that is not all, the wide range of feeding solutions includes:

- CENTRIFUGAL DISC FEEDERS

- POCKET DISC FEEDERS

- DOUBLE DISC FEEDERS

- ROLLWAY FEEDERS

- WATERFALL FEEDERS

- VIBRATORY BOWL FEEDERS

- CONICAL FEEDERS

- CONDUCTOR FEEDERS

- ELEVATORS

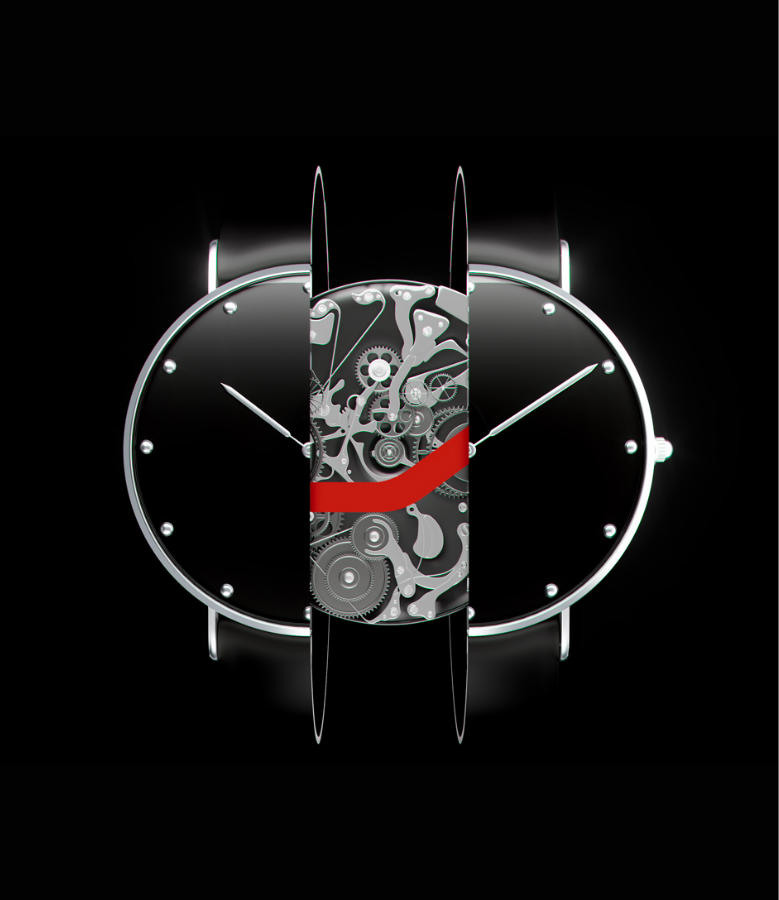

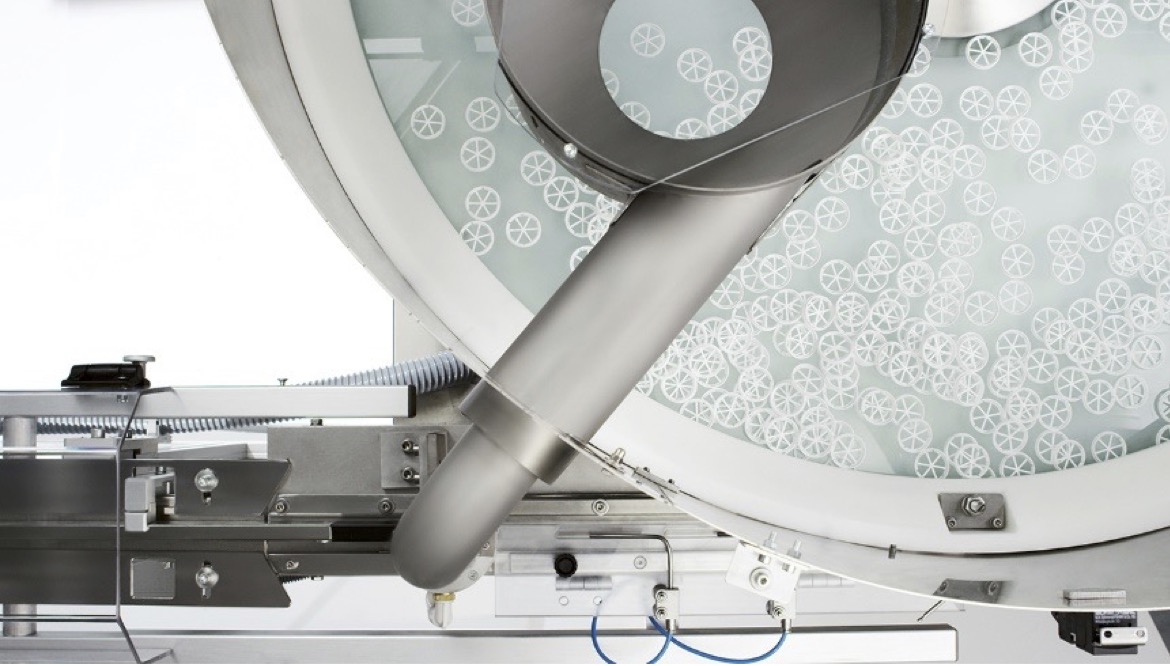

Centrifugal disc feeders

Centrifugal feeders are generally suitable for the sorting and orientation of parts having a bigger diameter than height. The sorting function is granted by the centrifugal force created by the rotation of the base plate, pushing the parts towards the outer diameter of the sorter. Due to the geometry and position of their center of gravity, the parts, during their movement inside the sorter, will be placed in different positions according to specific percentages.

Pocket disc feeders

Pocket Disc feeders are generally suitable for the sorting and orientation of parts having a bigger height than diameter. They have a specific inclination that allows for the product to gather in the bottom part, trying to find its position inside the pockets machined in the plastic sectors assembled on the rotation disc.

Double disc feeders

Double Disc feeders can be considered the most flexible feeders within the range due to the fact they can process parts with very different shapes, dimensions and geometrical characteristics. Parts can have bigger diameters than heights or vice versa. They can have different , non circular, shapes; plus, flow packed products can be sorted inside it.

Rollway feeders

Rollway feeders are generally suitable for the sorting and orientation of parts having conical geometrical shapes, or cylindrical shapes with bigger heights than diameters. For cylindrical parts, a circular flange or a ring are needed in order to allow for the part to be hung on the rollers. Furthermore, the parts’ center of gravity should be clearly unbalanced on one side, in order for the parts to ease the sorting process.

Waterfall feeders

Waterfall vertical feeders are generally suitable for the sorting and orientation of parts having a bigger diameter than height, with a clearly unbalanced center of gravity with respect to the geometrical shape. The sorting function is given by the product’s geometry and its center of gravity position.

Vibratory bowl feeders

Vibratory bowl feeders can handle very different feed rates producing a uniform product flow that provides gentle handling. The vibrating drive units can be developed according to the different types of components that need to be oriented.

Conical feeders

Conical feeders feed and orientate products carefully, guaranteeing a consistent and accurate flow of components to the next workstation. They have been designed to handle components from all areas of industry.

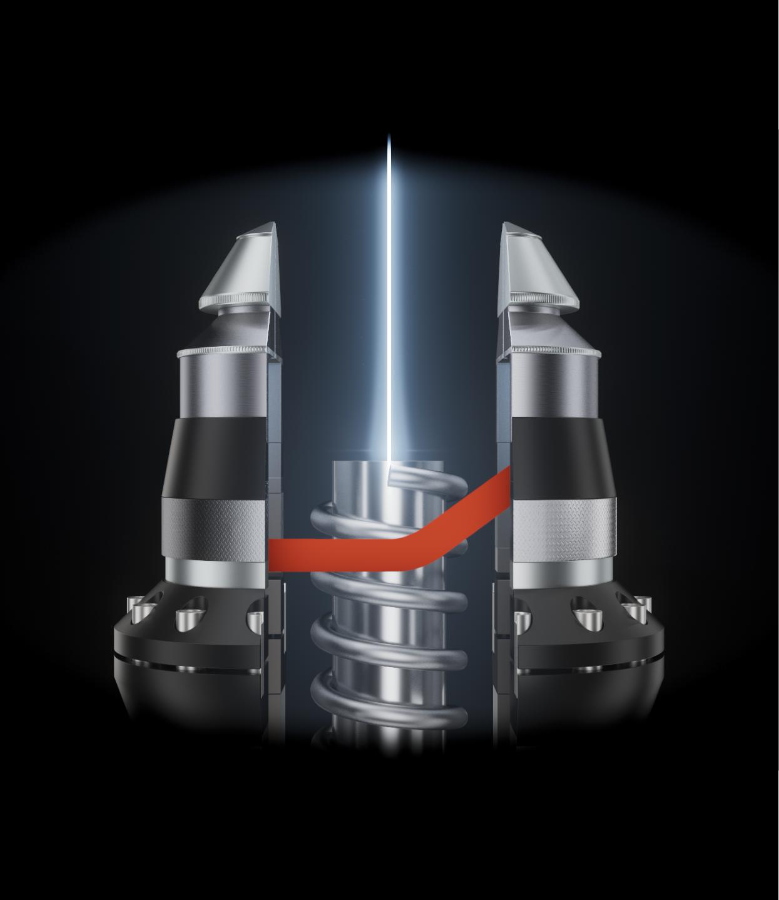

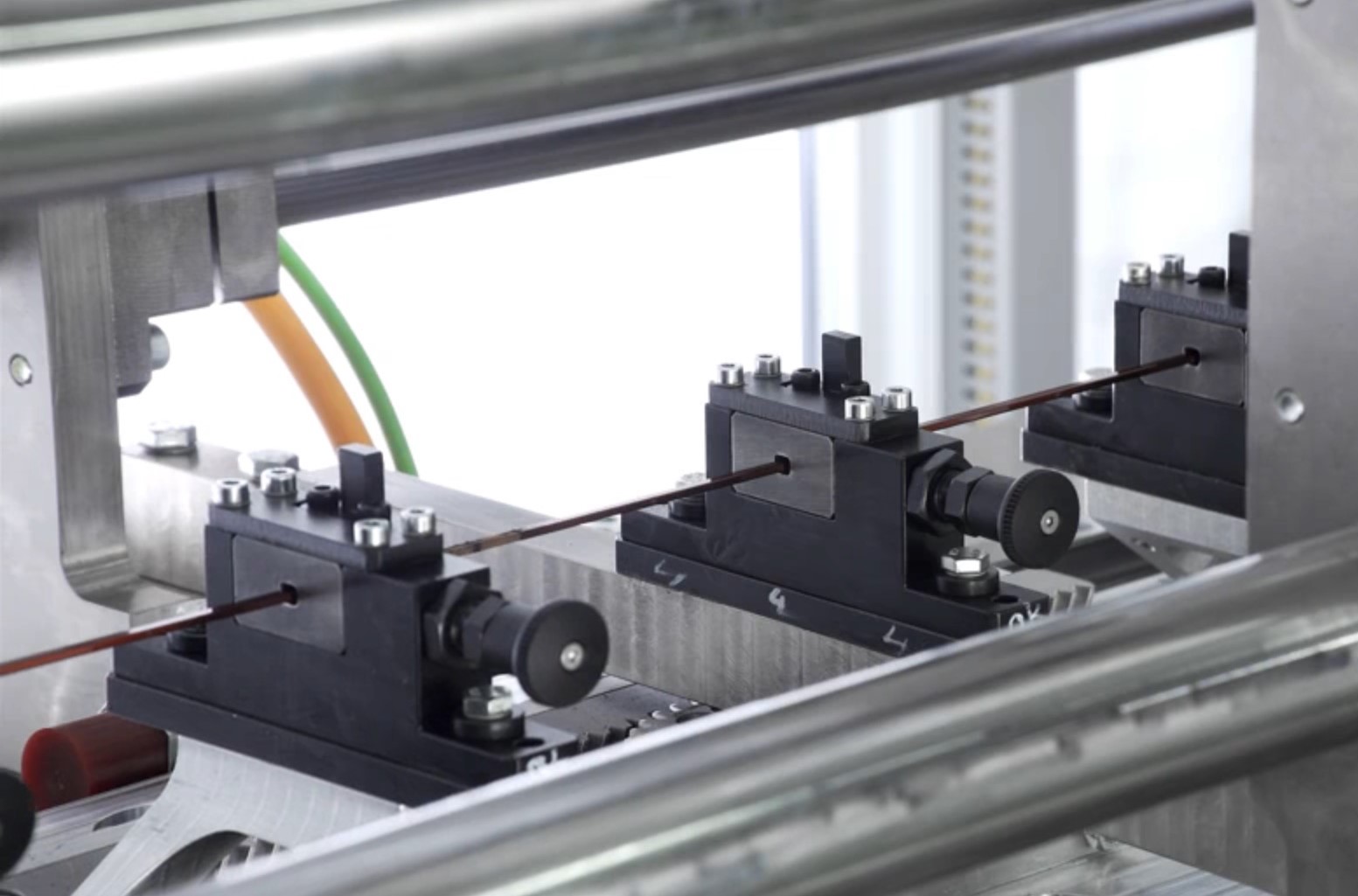

Conductor feeders

Conductor feeding systems are frequently used in the automotive, emobility and electric motor assembly solutions to feed wire into the production flow. In hairpin technology for stator production, the NC axis-driven, dual-clamp wire feed unit enables accurate control of the feed system, which can provide extremely high performance during the single hairpin forming process step.

Elevators

Elevators are always used to provide parts inside the feeders. According to the requested autonomy of parts, elevators can have static or motorized hopper, with integrated conveyor belt that can dose the parts in the charging zone of the elevator belt. Motorized hoppers are particularly suitable for products that require a gentle dosing in order to preserve as much as possible the surface quality of parts that tend to become entangled to each other during the charging moment.

- ELEVATORS WITH STATIC HOPPER

- ELEVATORS WITH MOTORIZED HOPPER