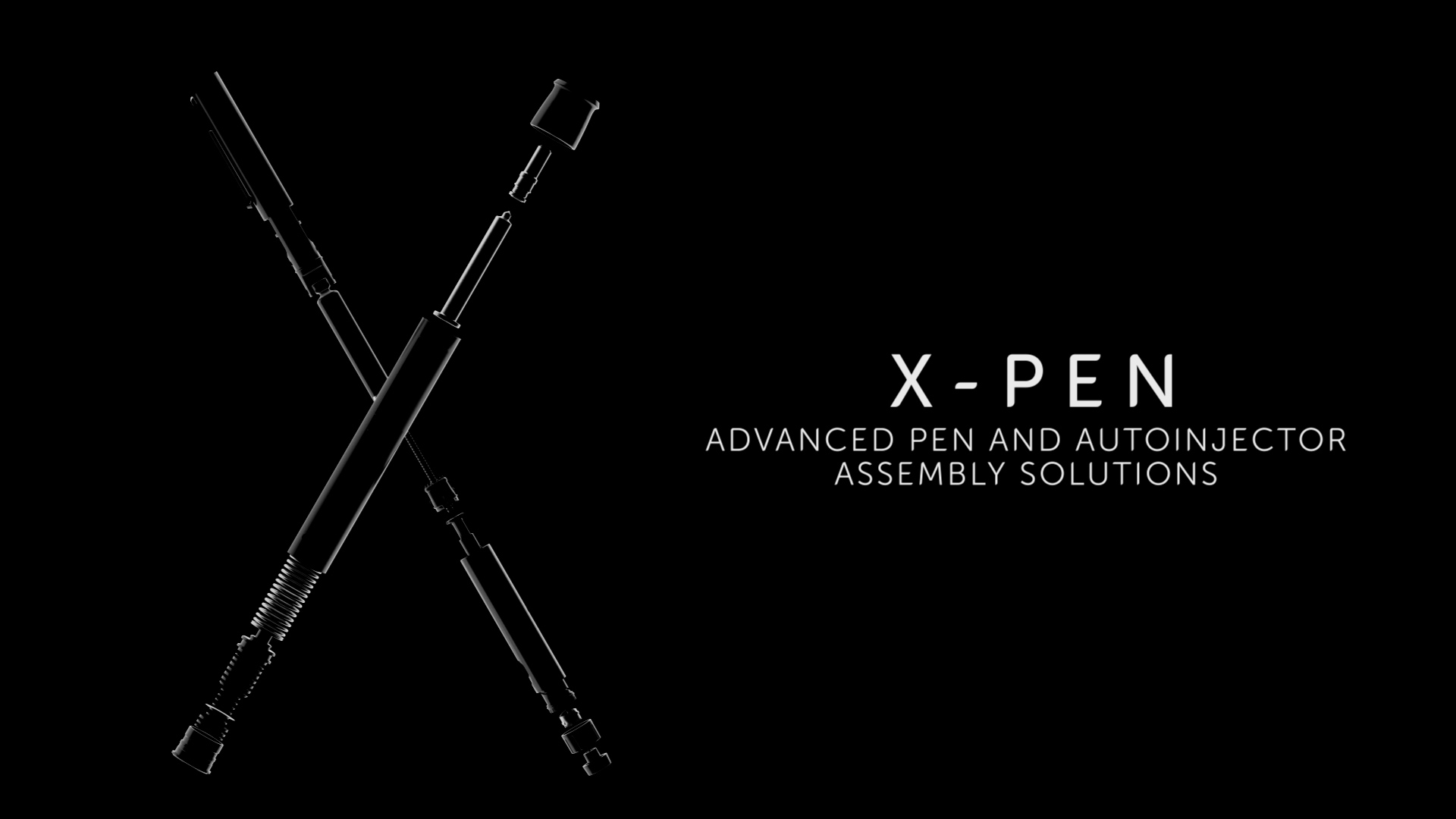

X-PEN advanced pen and autoinjector assembly solutions

A new approach for pens, autoinjectors and needle safety devices final assembly systems.

The Business Unit Dedicated to Medical Assembly & Process Technologies

IMA MED-TECH’s team, comprising +600 professionals across 6 international locations, boasts top-tier technical skills and a solid market reputation with more than 60 complete assembly lines installed worldwide. This expertise ensures that IMA MED-TECH can provide advanced assembly solutions, both standard and customized, alongside robotic solutions and digital platforms, fully compliant with strict industry standards.

By leveraging the cutting-edge solutions and extensive experience of IMA AUTOMATION, IMA MED-TECH positions itself as a strategic partner for CMOs and large pharmaceutical companies, offering turnkey solutions from assembly to packaging. This integration of capabilities reinforces the IMA Group’s dedication to continuous innovation, higher quality standards, and sustainable production in the MedTech sector.

INNOVATION CENTER

Discover the IMA AUTOMATION Innovation Center: where creativity meets technology to shape the future of assembly automation and redefine industry excellence.

IMA MED-TECH

is the business unit of IMA AUTOMATION, focused exclusively on medical assembly technologies. As part of the IMA GROUP, IMA MED-TECH leverages the group’s strength and over 60 years of industry experience to drive innovation and excellence in automation, assembly and process.

With its global network of companies, IMA MED-TECH designs and manufactures advanced technology lines for the assembly of medical devices, drug delivery injectors, inhalers, in vitro diagnostics, point-of-care solutions, wearables, pharma caps and complete processing and packaging lines for contact lenses and ophthalmic inserters.

This business unit centralizes expertise in medical technology, enhancing the IMA Group’s commitment to the MedTech sector.

The Business Unit Dedicated to Medical Assembly & Process Technologies

IMA MED-TECH’s team, comprising +600 professionals across 6 international locations, boasts top-tier technical skills and a solid market reputation with more than 60 complete assembly lines installed worldwide. This expertise ensures that IMA MED-TECH can provide advanced assembly solutions, both standard and customized, alongside robotic solutions and digital platforms, fully compliant with strict industry standards.

By leveraging the cutting-edge solutions and extensive experience of IMA AUTOMATION, IMA MED-TECH positions itself as a strategic partner for CMOs and large pharmaceutical companies, offering turnkey solutions from assembly to packaging. This integration of capabilities reinforces the IMA Group’s dedication to continuous innovation, higher quality standards, and sustainable production in the MedTech sector.

INNOVATION CENTER

Discover the IMA AUTOMATION Innovation Center: where creativity meets technology to shape the future of assembly automation and redefine industry excellence.

IMA MED-TECH

is the business unit of IMA AUTOMATION, focused exclusively on medical assembly technologies. As part of the IMA GROUP, IMA MED-TECH leverages the group’s strength and over 60 years of industry experience to drive innovation and excellence in automation, assembly and process.

With its global network of companies, IMA MED-TECH designs and manufactures advanced technology lines for the assembly of medical devices, drug delivery injectors, inhalers, in vitro diagnostics, point-of-care solutions, wearables, pharma caps and complete processing and packaging lines for contact lenses and ophthalmic inserters.

This business unit centralizes expertise in medical technology, enhancing the IMA Group’s commitment to the MedTech sector.

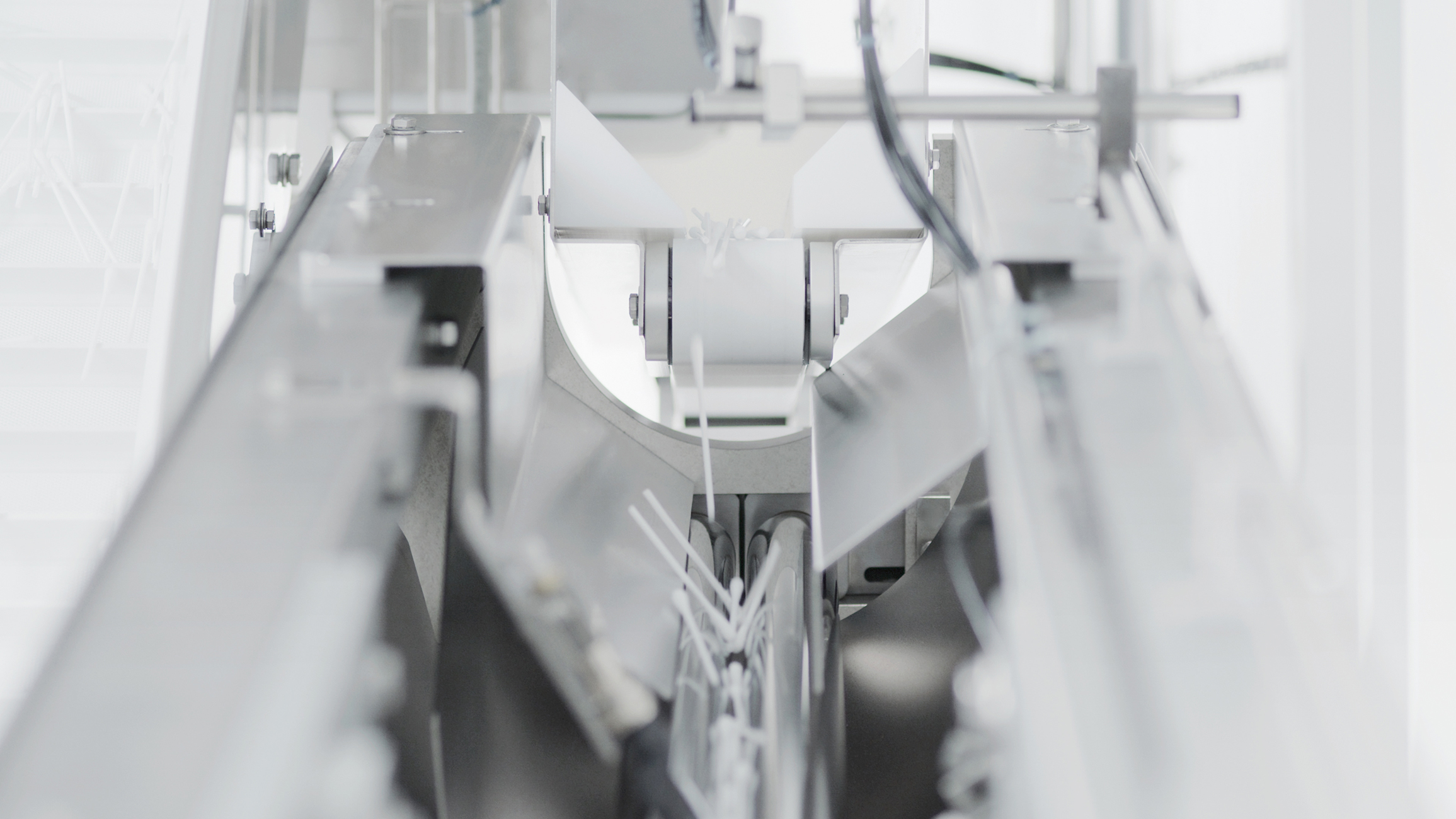

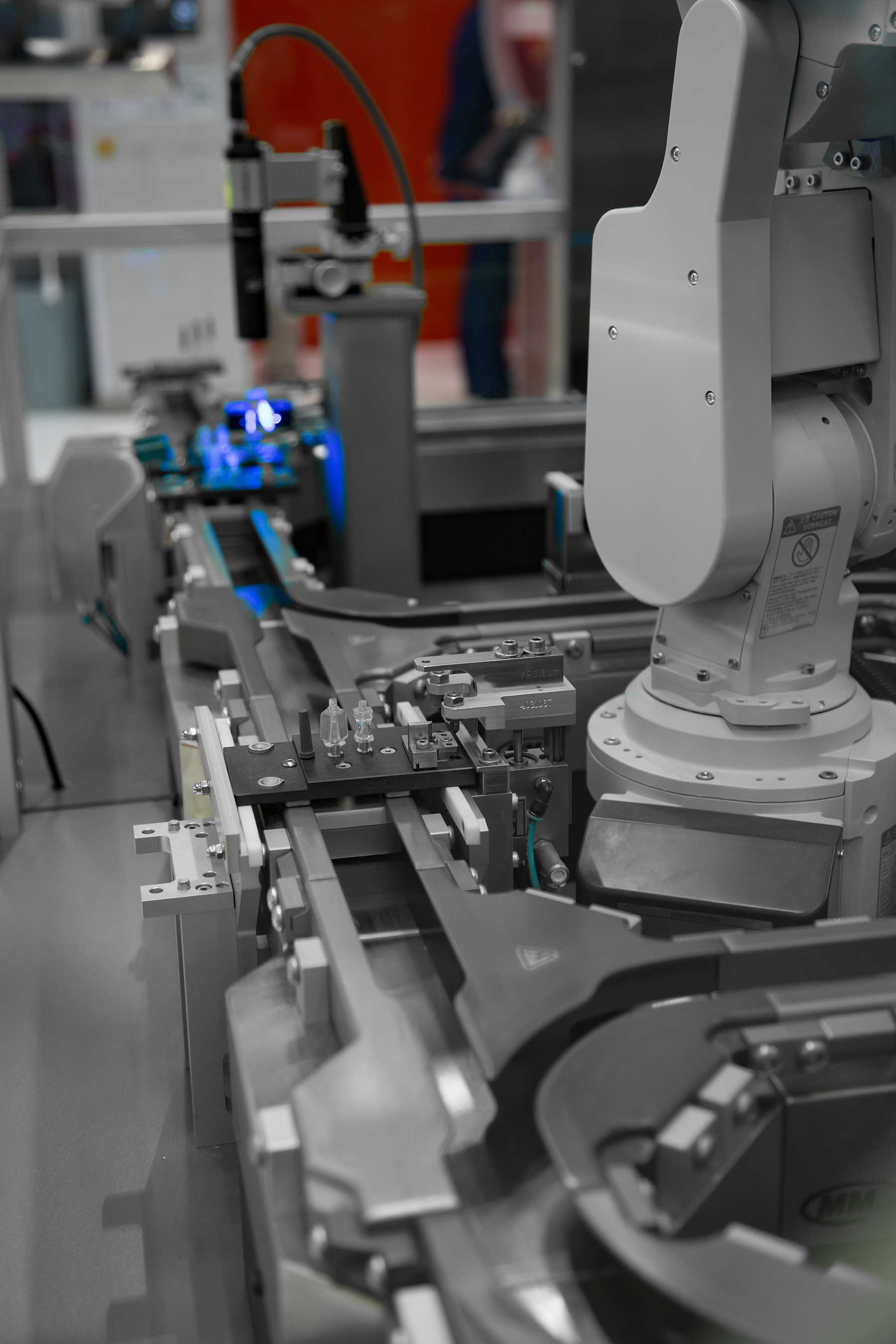

Flexible and reliable assembly solutions

Each device has its own unique challenges. With a range of standard platforms, linear and rotary, along with indexing and continuous motion assembly capabilities at our disposal, we are able to optimize the design to suit the individual needs of the assembly process, taking into account production requirements and at the same time optimising the available floor space in your clean room.

Flexible and reliable assembly solutions

Each device has its own unique challenges. With a range of standard platforms, linear and rotary, along with indexing and continuous motion assembly capabilities at our disposal, we are able to optimize the design to suit the individual needs of the assembly process, taking into account production requirements and at the same time optimising the available floor space in your clean room.

Drug Delivery

Injectables

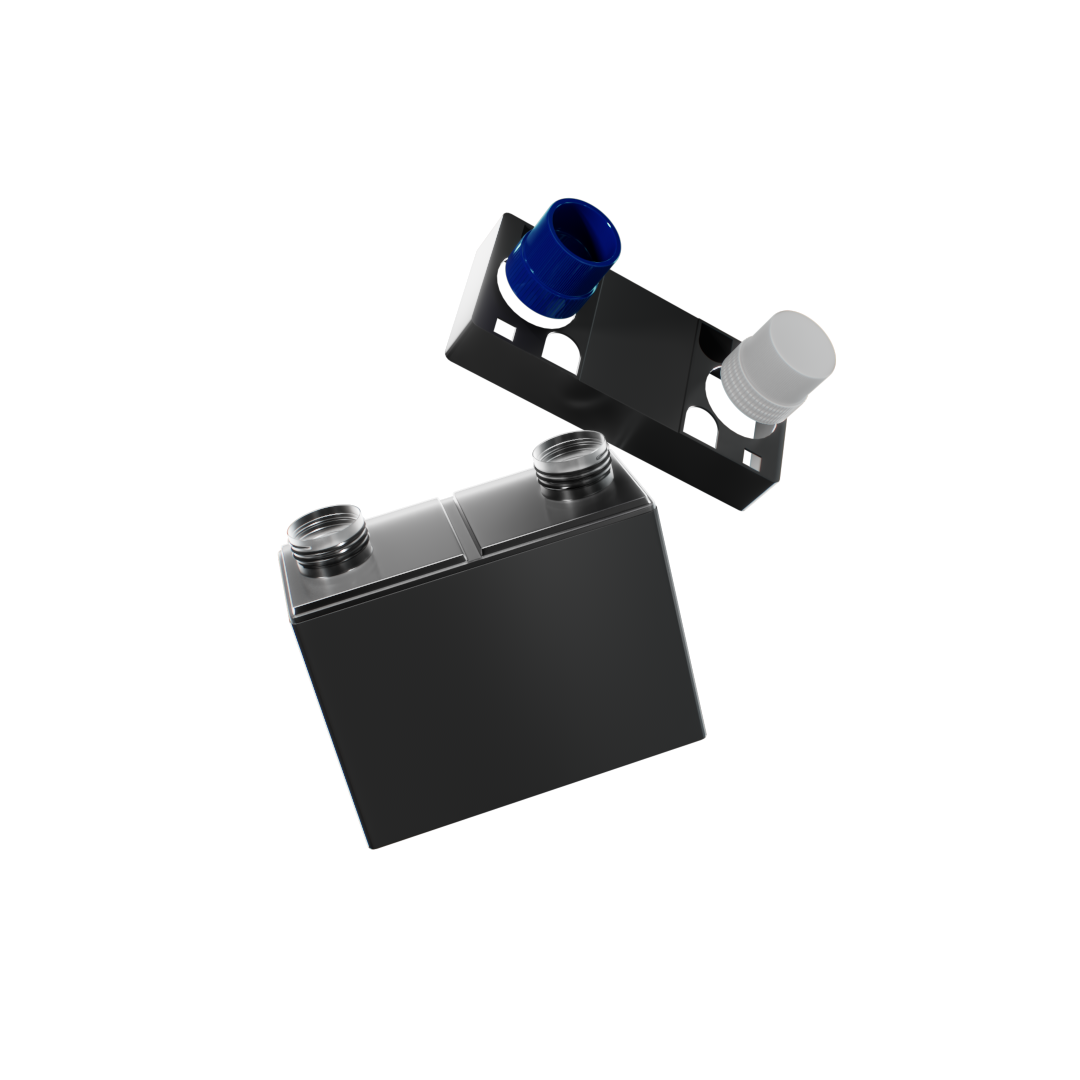

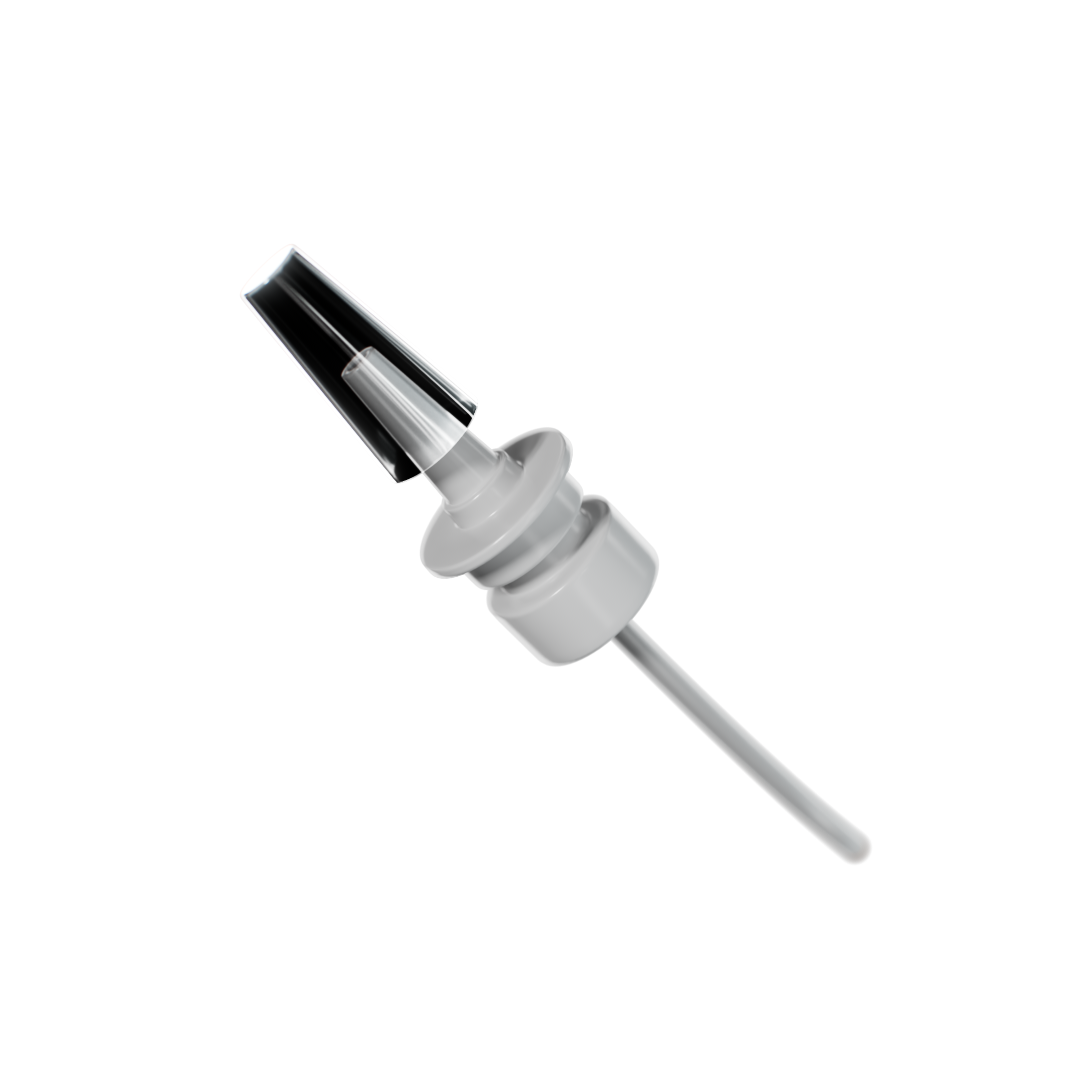

Deeply experienced in the assembly of pens and auto-injectors: from automatic denesting systems for pre-filled syringes to dosing mechanisms, in addition to power-pack assembly and final product assembly including drug manipulation.

Inhalers

IMA AUTOMATION’s expertise ranges from pre-assembly phases to the product’s final assembly stage, including drug manipulation, packaging and all of the challenges that come with the developing and manufacturing of DPIs, MDIs and Dose Counters.

DPIs

IMA MED-TECH offers advanced, flexible solutions for dry powder inhaler (DPI) assembly, covering every stage from initial development to high-performance automation. In collaboration with IMA Active, which delivers precision dosing and sophisticated processing, IMA MED-TECH provides cutting-edge solutions for DPI production and assembly, ensuring accuracy, efficiency, and reliability.

Eye Care

Contact Lenses

Designing space saving and high performance contact lens manufacturing lines, IMA AUTOMATION provides total control of the contact lens manufacturing process for coloroured, daily or semipermanent contact lenses. Lines are designed to implement robotizing, filling, laser and inspection systems, in order to duly execute lens releasing, washing and packaging operations. This also ensures high versatility in the handling of different sizes of lenses, thanks to quick mechanical and control changeovers.

Ophthalmic Inserters

Complete assembly and functional testing of lens inserters, lens processing and final device with all necessary coatings in place. Each assembly equipment consists of a platform that forms the basis for a tailor made solution, where stations and assembly technologies are added in accordance with customer needs and requirements.

Diagnostics

Wearables

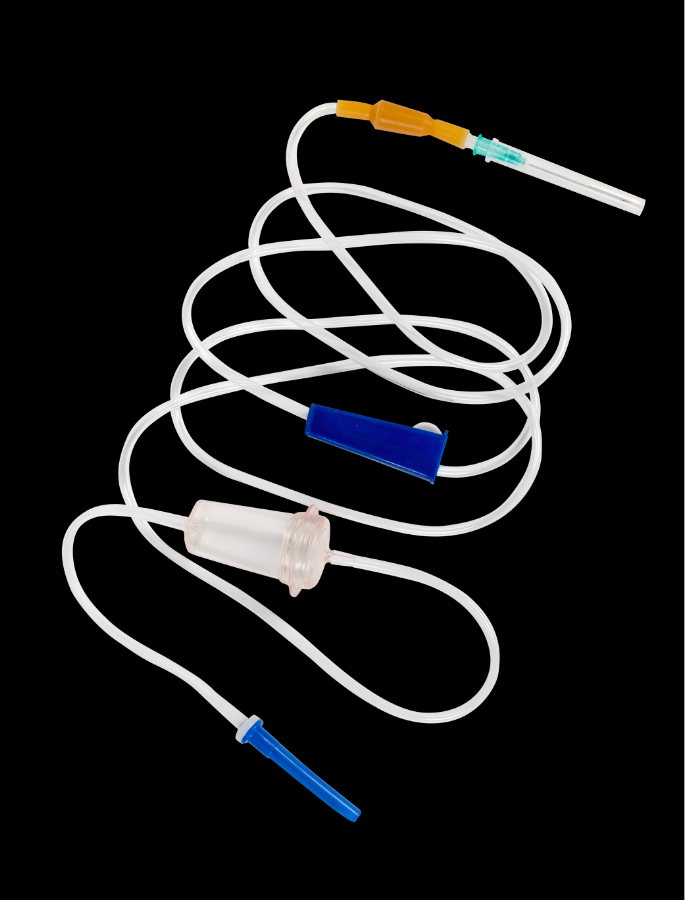

Tubing Sets

Surgical Instruments

Sutures

Flexible automated solutions for multivariant surgical sutures assembly and crimping. A wide range of needles and threads can be handled and a fast product changeover time provides the flexibility of producing large or small batches. Each suture is subjected to a pull test to guarantee a constant high quality thread needle combination. The finished and tested product is then unloaded into stainless steel receptacles for easy handling.

Pharma Caps

Advanced Medical Devices assembly from within

Technologies

Each assembly system consists of a platform that forms the basis for a made-to-measure solution to satisfy specific needs. Stations and assembly technologies are added in accordance with customer requirements.

All technological platforms designed by IMA AUTOMATION are a step up from the most advanced electronic and mechanical automation technologies available on the market. This is why we call our technology “Advanced Assembly Technology“.

Technologies

Each assembly system consists of a platform that forms the basis for a made-to-measure solution to satisfy specific needs. Stations and assembly technologies are added in accordance with customer requirements.

All technological platforms designed by IMA AUTOMATION are a step up from the most advanced electronic and mechanical automation technologies available on the market. This is why we call our technology “Advanced Assembly Technology“.

Discover more, download the brochure

Check

latest news

Locations

Via Kennedy, 17 - Via Parini, 1

Zola Predosa, 40069

Bologna | Italy

Tianyi Road, Building 1,

No 605 - 607,

Qingpu District, 201712

Shanghai | China

Plot 96, Solok Bayan Lepas,

Bayan Lepas Industrial Park,

Phase IV, 11900

Penang | Malaysia