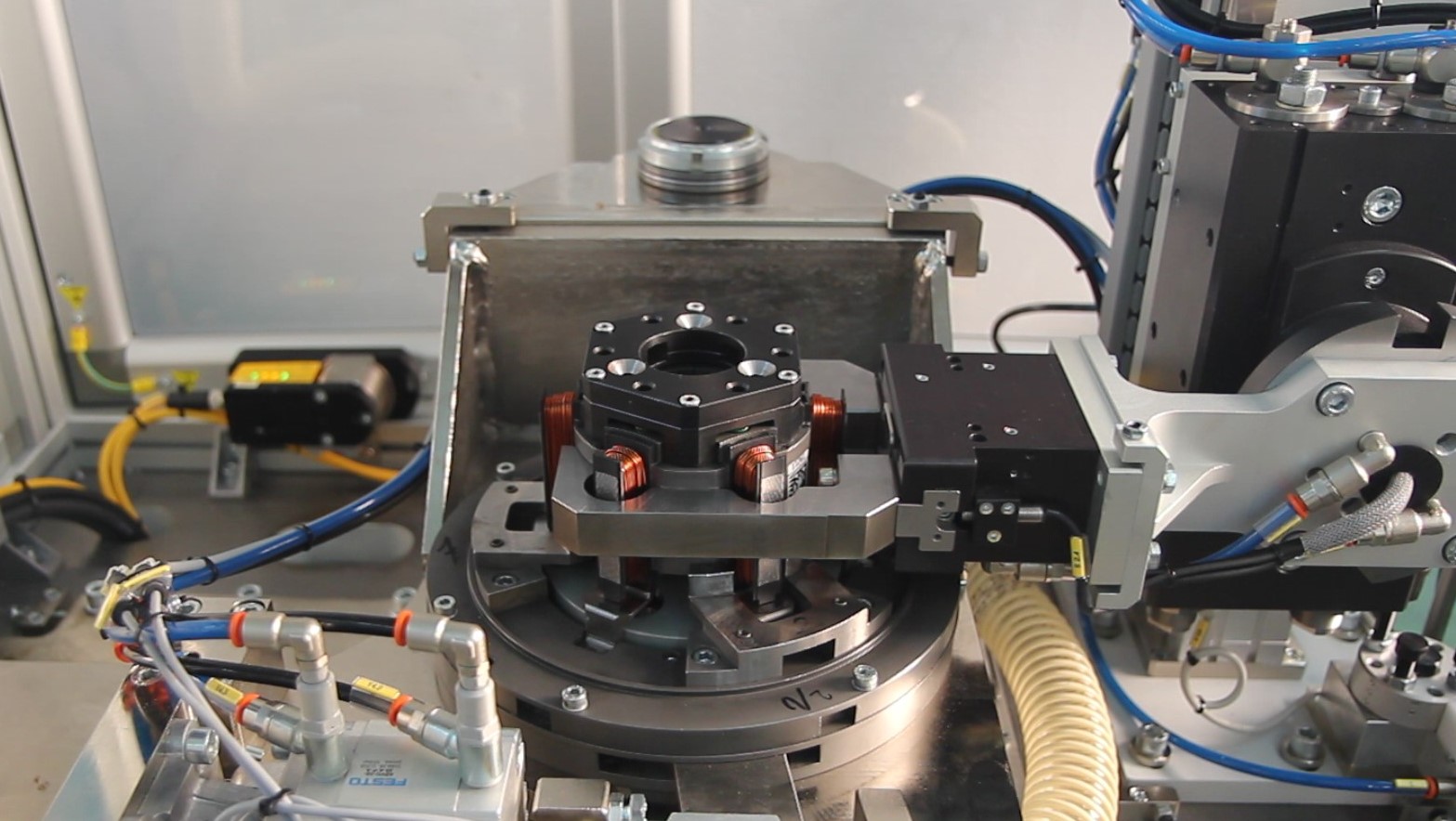

Needle Winding Technology

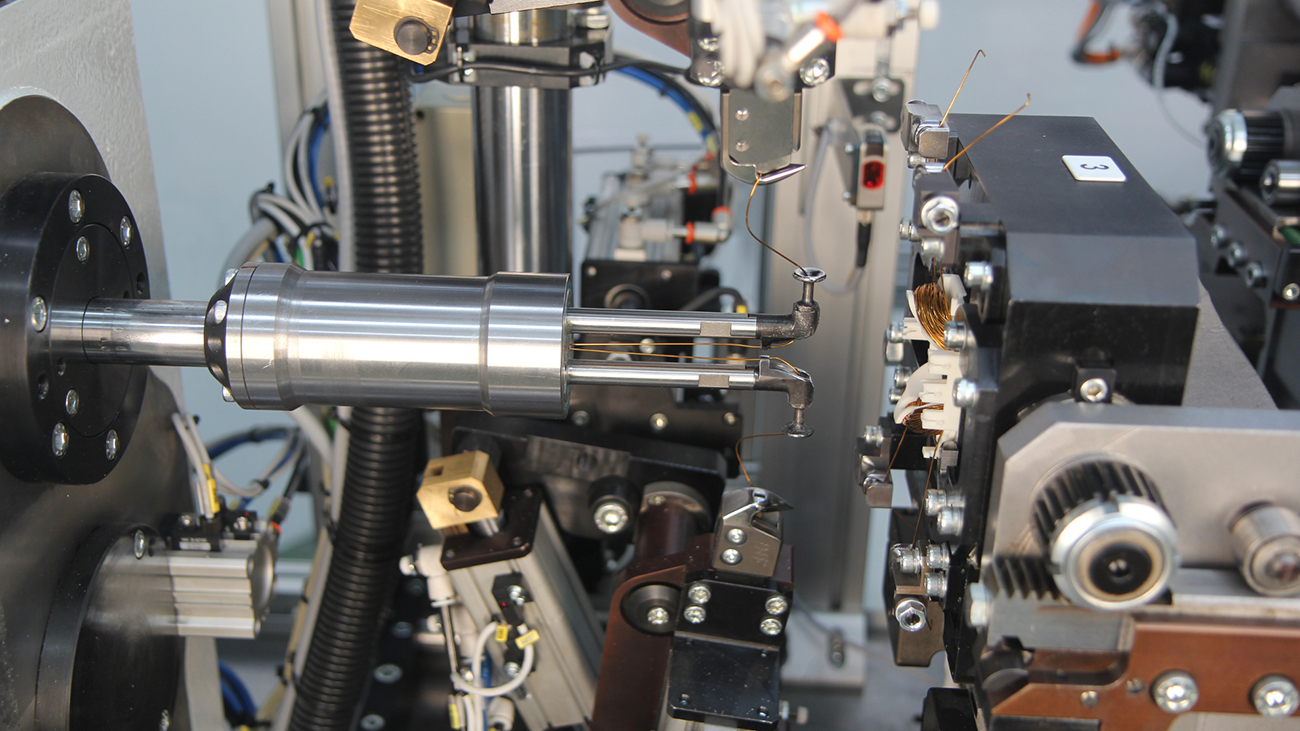

With a great experience in the manipulation of the wire, IMA AUTOMATION can provide many customized solutions. High speed needle winding with single or multiple stations to reach maximum productivity.

This technology is extremely flexible and dynamic. The head of the needle has the characteristic of rotating the head for wire routing on the upper and bottom part of the product. This solution defines an automatic system to increase the productivity and the wire stratification.

IMA AUTOMATION designs and manufatures automatic lines with needle technology for:

- Single pole stators

- Outer slot stators

- Inner slot stators

- Two poles stators

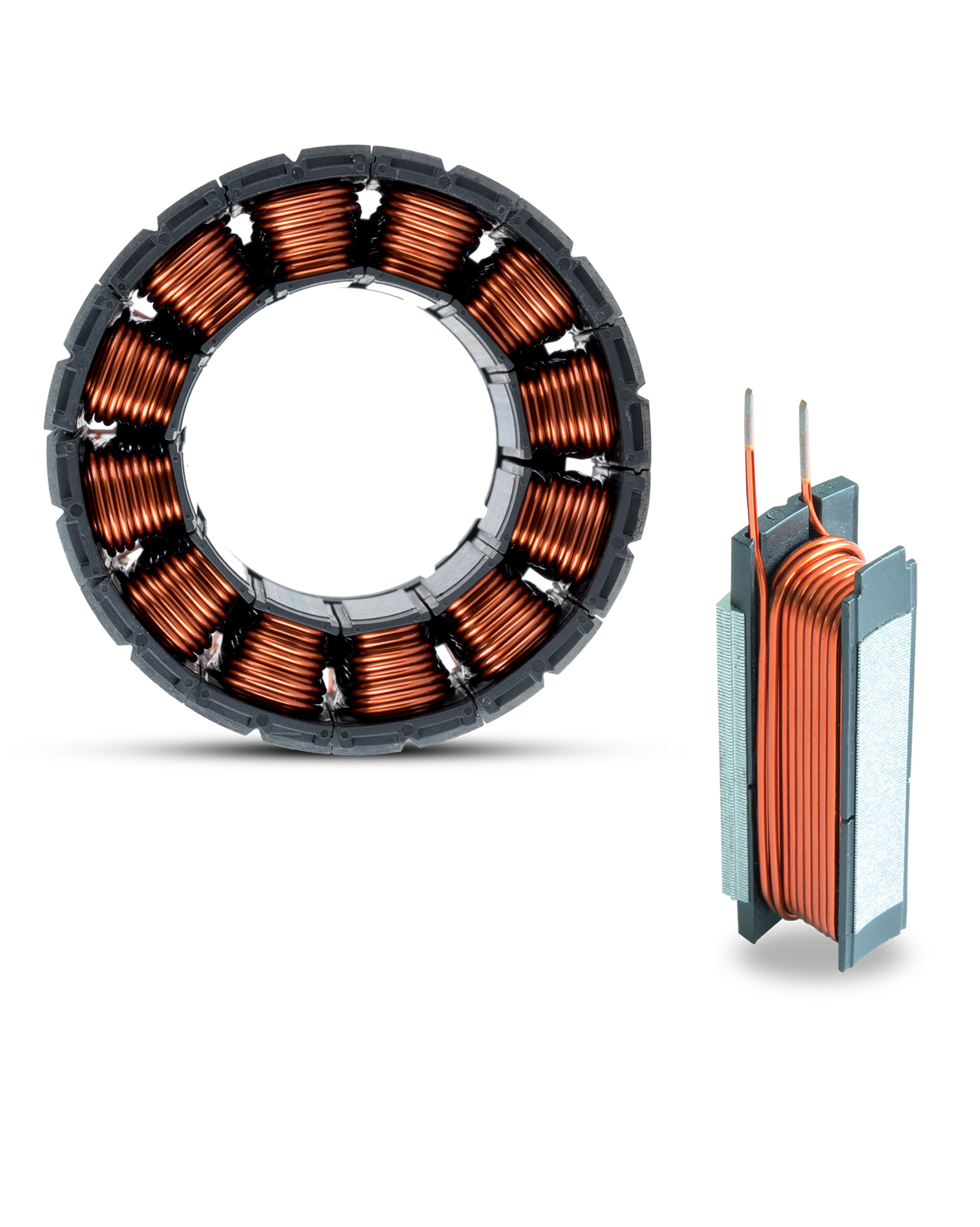

Single pole stator

IMA AUTOMATION offers customized production and fully automatic processes for the single poles assembling, pole laser welding, bus-bar or terminals fusing, hot-drop, and electrical testing. Other custom-made machines and process according to customer’s product. All lines are designed with multiple stations machines to increase productivity and reduce operating space. In addition, is available a quick change-over tooling to optimize production changeover times.

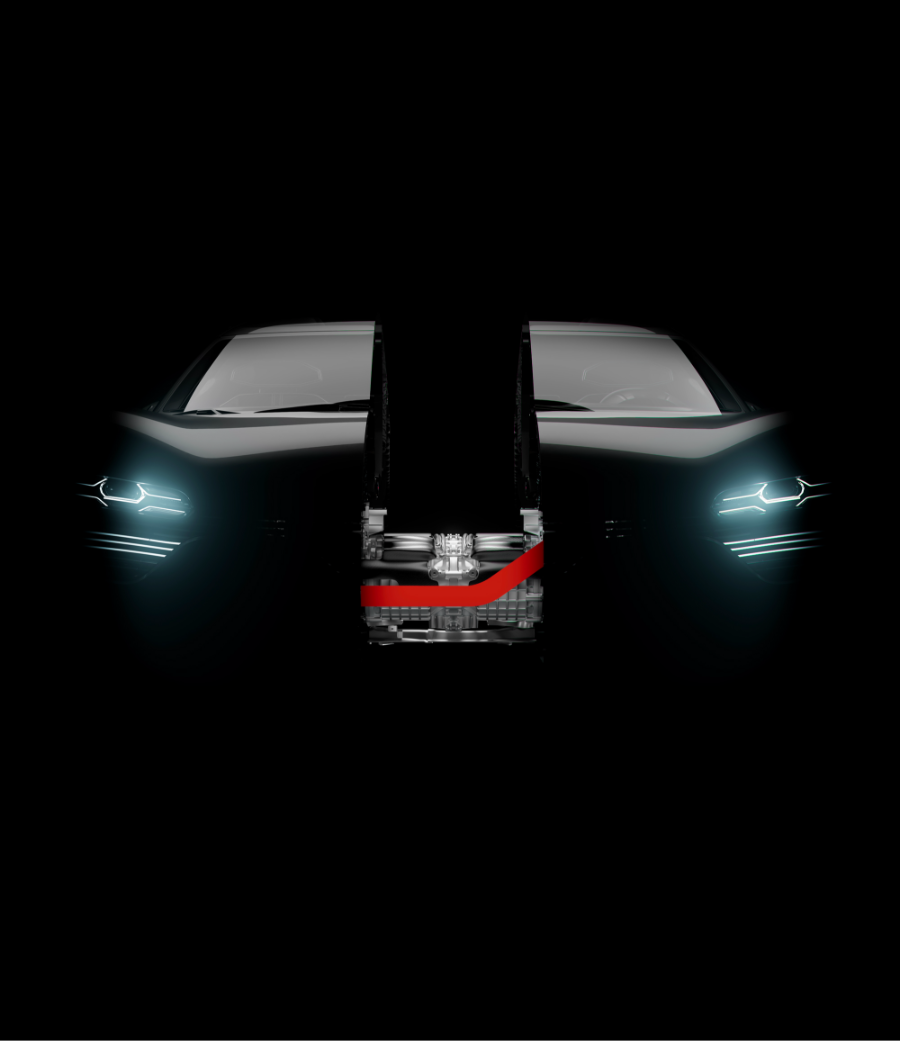

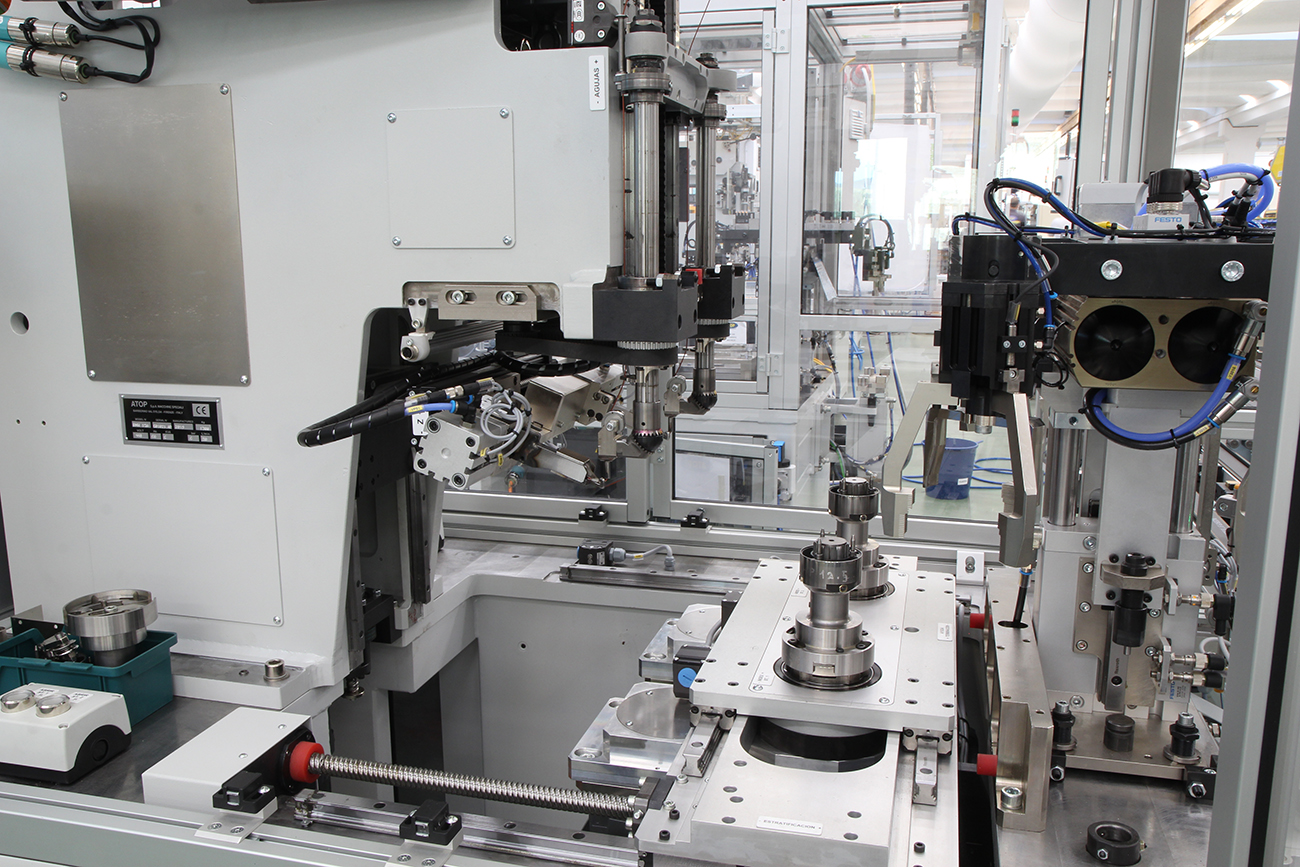

Outer slot stator

IMA AUTOMATION provides line for stators designed with outer slots. The machines are able to wind a high number of turns at hight speed and to guarantee maximum performance, efficiency, process repeatability , flexibility and reliability. The fully automatic wire startification guarantees an high slot fill and an excellent control of each phase of the process.

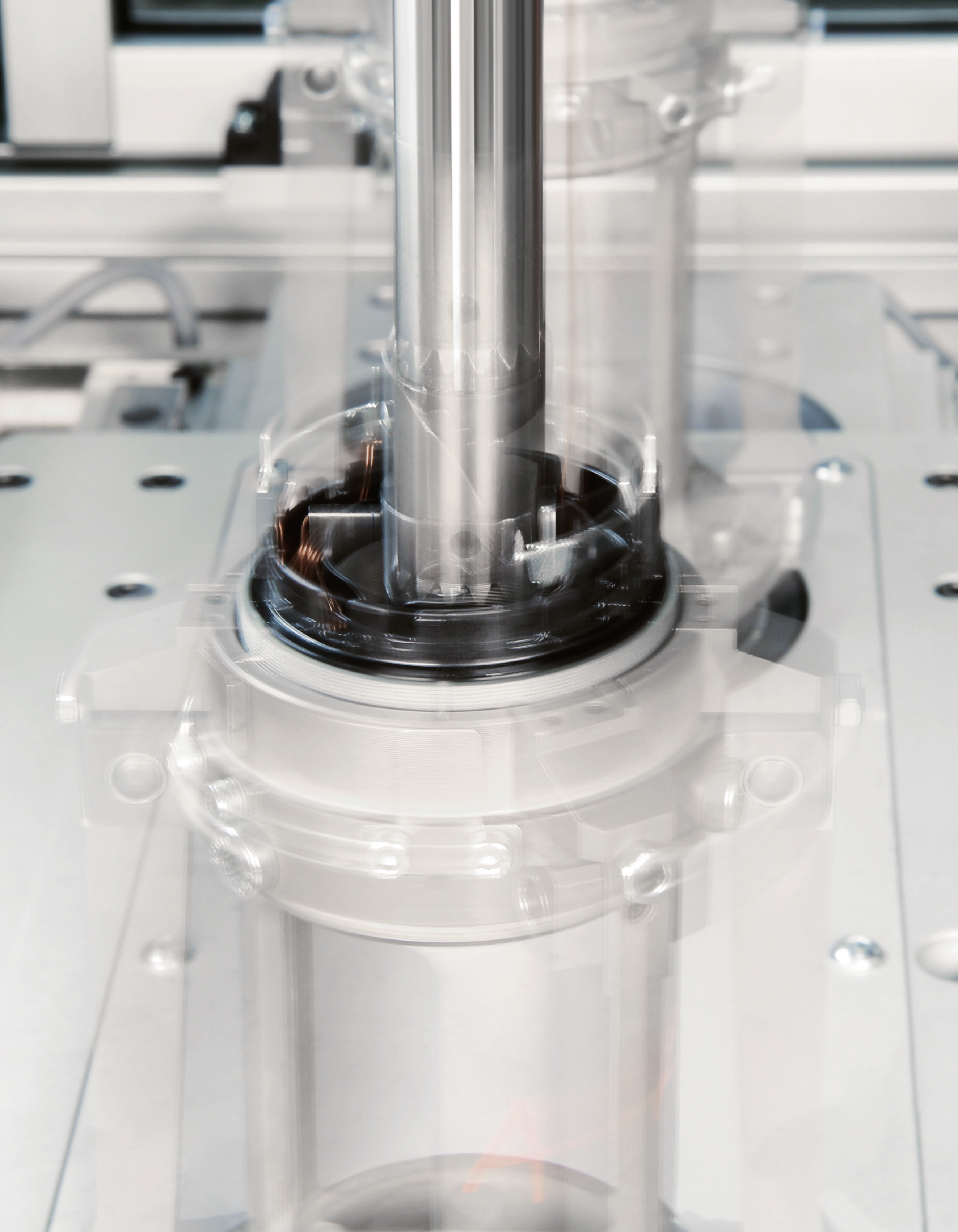

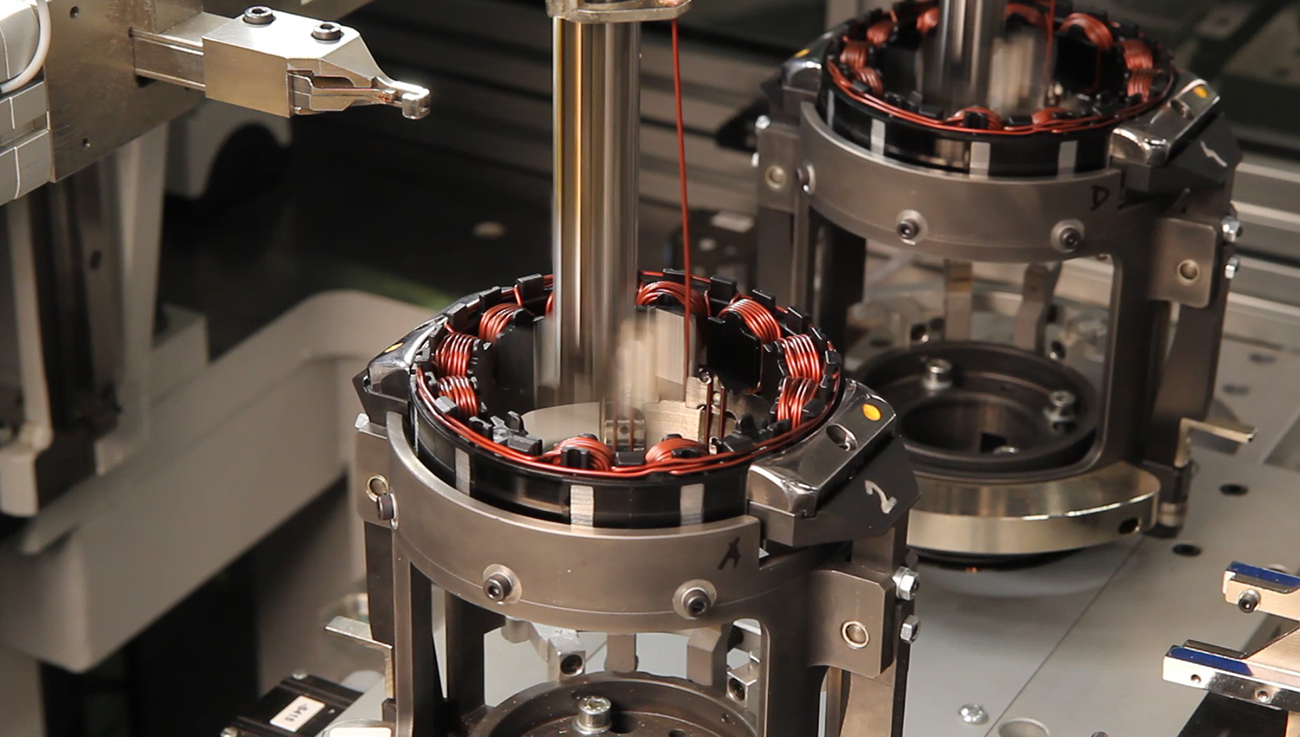

Inner slot stator

IMA AUTOMATION know-how and continuous innovation allow to supply tailored solutions with high technological content to produce the latest generation electric motors, which are more and more efficient, compact and with reduced energy consumption. The geometries of the inner slot stators permit to design fully programmable wire stratification by needle winding technology for high slot fill and accurate coil wire positioning.

Two poles stator

Automatic lines are deisgned by IMA AUTOMATION for the production of universal stator windings in a two-pole electric motor. The wire is wound by a needle automatic process through the two poles.