The Business Unit dedicated to Electric Vehicle Assembly Technologies

The business unit operates with a global footprint, supported by over 300 skilled professionals distributed across five international locations. IMA EV-TECH's facilities are strategically positioned in Italy, Switzerland, the United States, Malaysia, and China, allowing the company to provide comprehensive support to its customers worldwide. This global presence ensures IMA EV-TECH's efficient service for the automotive industry’s diverse and evolving needs with tailored solutions for each market.

One of the key strengths of IMA EV-TECH is its integration within IMA AUTOMATION's extensive network of companies, which includes nearly 600 patents and decades of experience in assembly processes across different sectors. This wealth of knowledge and expertise positions IMA EV-TECH as a leader in innovation and technological advancements for the EV industry. By leveraging these resources, IMA EV-TECH offers turnkey solutions that cover every stage of the production process, from assembly to testing and system integration.

INNOVATION CENTER

Discover the IMA AUTOMATION Innovation Center: where creativity meets technology to shape the future of assembly automation and redefine industry excellence.

IMA EV-TECH

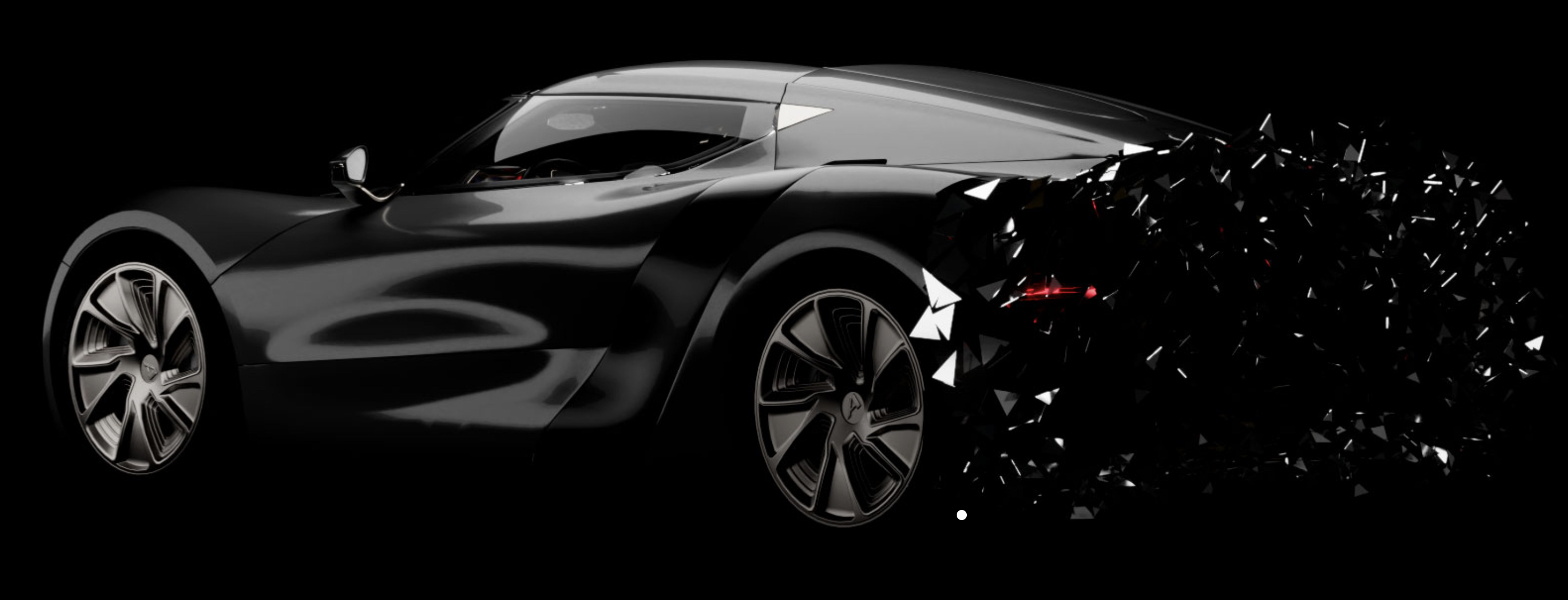

is the business unit of IMA AUTOMATION, entirely committed to electric vehicle (EV) assembly technologies. As a division of the IMA Group and a market leader in the design and manufacture of advanced technological lines for handling and assembling parts, IMA AUTOMATION created IMA EV-TECH to strengthen its presence in the rapidly evolving electric vehicle sector. This unit specializes in the development of complete line and assembly technologies for EV solutions such as battery cells (cylindrical and prismatic), fuel cells, e-axles, e-motors, stators and rotors.

IMA EV-TECH stands out for its ability to meet the specific needs of automotive manufacturers and suppliers. The unit provides cutting-edge assembly platforms, both standardized and fully customized, that are designed to meet the most demanding industry standards. In addition to assembly solutions, IMA EV-TECH delivers robotic systems, digital platforms, and virtual resources, enabling its partners to achieve optimal efficiency and innovation in production processes.

The Business Unit dedicated to Electric Vehicle Assembly Technologies

The business unit operates with a global footprint, supported by over 300 skilled professionals distributed across five international locations. IMA EV-TECH's facilities are strategically positioned in Italy, Switzerland, the United States, Malaysia, and China, allowing the company to provide comprehensive support to its customers worldwide. This global presence ensures IMA EV-TECH's efficient service for the automotive industry’s diverse and evolving needs with tailored solutions for each market.

One of the key strengths of IMA EV-TECH is its integration within IMA AUTOMATION's extensive network of companies, which includes nearly 600 patents and decades of experience in assembly processes across different sectors. This wealth of knowledge and expertise positions IMA EV-TECH as a leader in innovation and technological advancements for the EV industry. By leveraging these resources, IMA EV-TECH offers turnkey solutions that cover every stage of the production process, from assembly to testing and system integration.

INNOVATION CENTER

Discover the IMA AUTOMATION Innovation Center: where creativity meets technology to shape the future of assembly automation and redefine industry excellence.

IMA EV-TECH

is the business unit of IMA AUTOMATION, entirely committed to electric vehicle (EV) assembly technologies. As a division of the IMA Group and a market leader in the design and manufacture of advanced technological lines for handling and assembling parts, IMA AUTOMATION created IMA EV-TECH to strengthen its presence in the rapidly evolving electric vehicle sector. This unit specializes in the development of complete line and assembly technologies for EV solutions such as battery cells (cylindrical and prismatic), fuel cells, e-axles, e-motors, stators and rotors.

IMA EV-TECH stands out for its ability to meet the specific needs of automotive manufacturers and suppliers. The unit provides cutting-edge assembly platforms, both standardized and fully customized, that are designed to meet the most demanding industry standards. In addition to assembly solutions, IMA EV-TECH delivers robotic systems, digital platforms, and virtual resources, enabling its partners to achieve optimal efficiency and innovation in production processes.

EV-Batteries

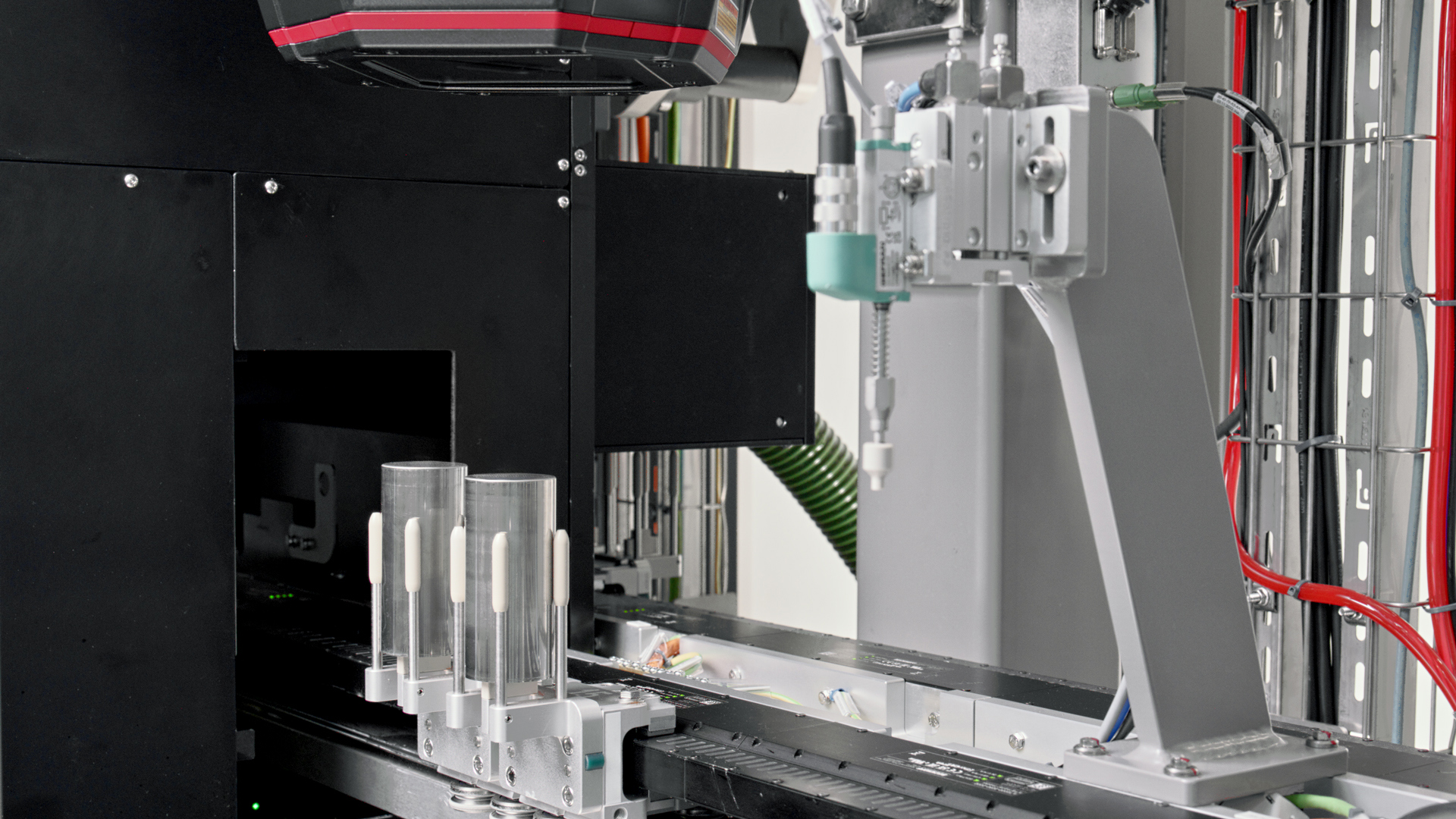

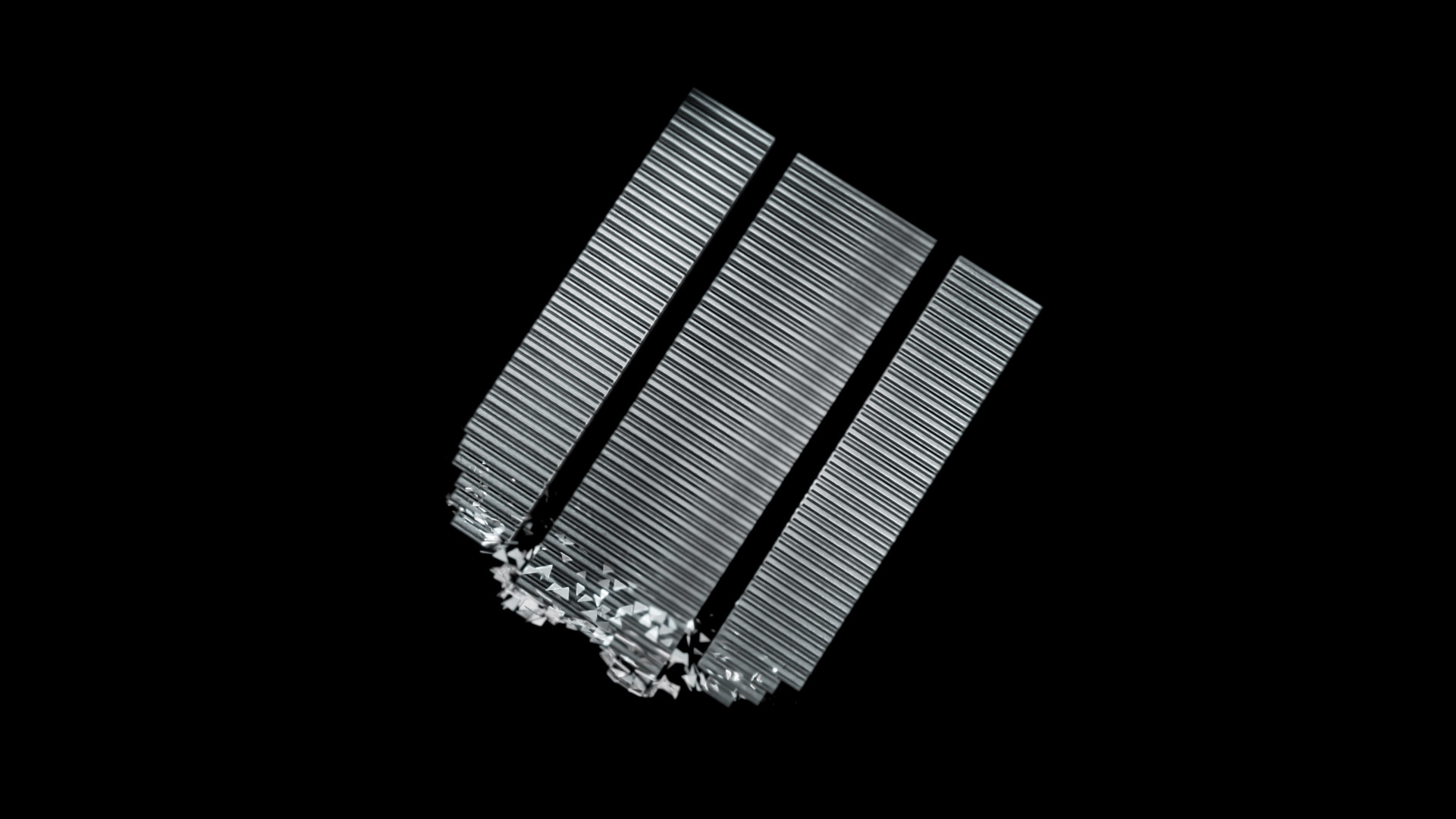

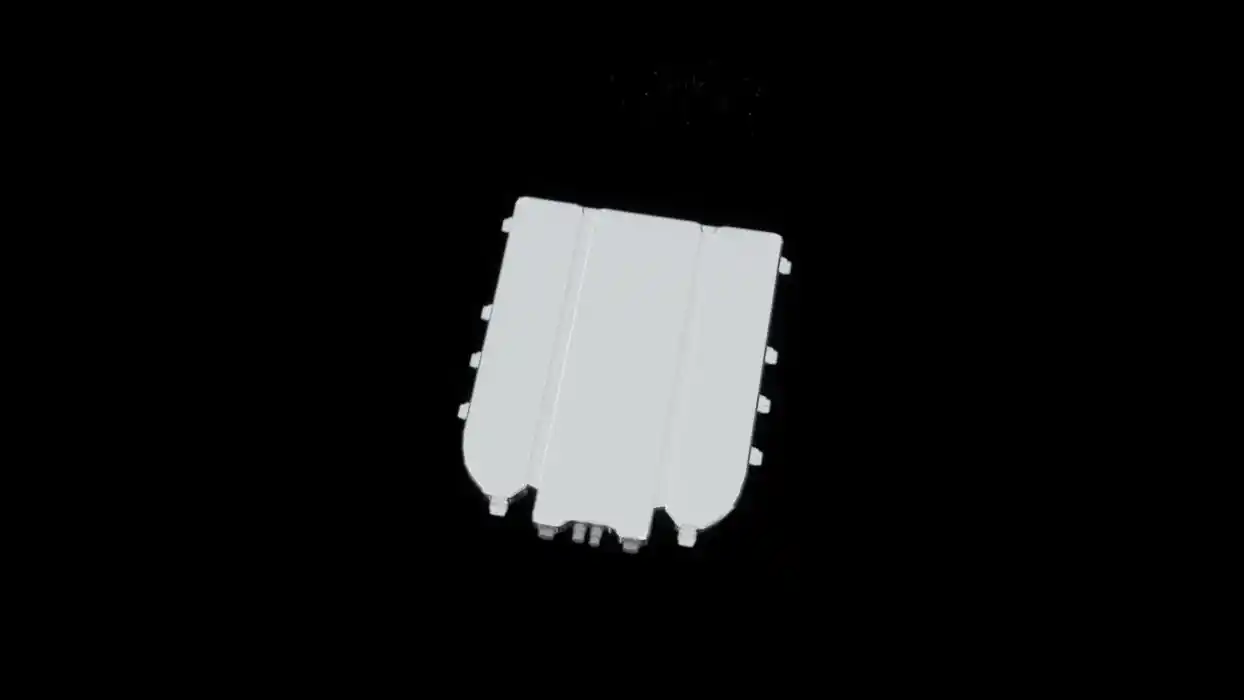

Prismatic Cell Assembly

Discover the latest stacking technology for prismatic cell assembly. Combining innovation and precision to guarantee high quality at each phase. Empower your plant with advanced processes.

Cylindrical Cell Assembly

Explore technological excellence in cylindrical battery cell manufacturing. Our machines ensure precise winding solutions and advanced filling and welding systems, crucial for optimal performance.

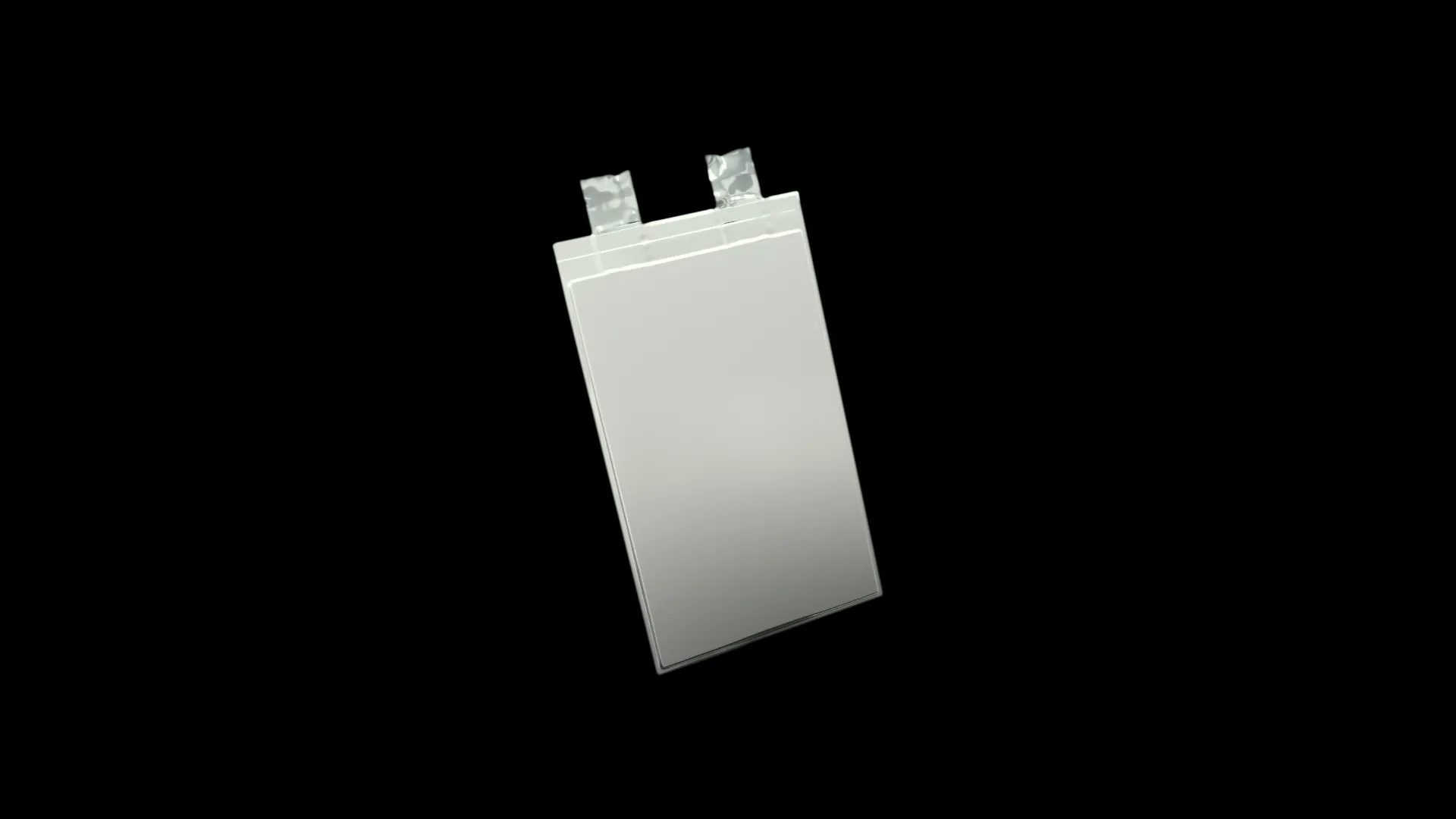

Pouch Cell Assembly

Leveraging the Group's extensive experience in pouch solutions, IMA EV-TECH offers process technologies that combine scalability, precision and speed. Our modular lines are designed to ensure high productivity and optimize assembly quality with cutting-edge welding and control systems.

Module and Pack Assembly

IMA EV-TECH offers turnkey solutions for every stage of the production process, from assembly to testing and system integration. Customized platforms integrate battery cell inspection and grading with module/pack assembly, supported by robotic systems and digital platforms to enhance efficiency and innovation.

Innovative Concepts

- Hybrid systems that combine hybrid, continuous and index-motion processes.

- Integration of multiple processes into a modular platform.

- Minimal product manipulation throughout the manufacturing flow.

- Up to a 50% reduction in space needed for clean and dry rooms.

- High reduction of cost of ownership.

EV-Batteries

du

Prismatic Cell Assembly

Discover the latest stacking technology for prismatic cell assembly. Combining innovation and precision to guarantee high quality at each phase. Empower your plant with advanced processes.

du

Cylindrical Cell Assembly

Explore technological excellence in cylindrical battery cell manufacturing. Our machines ensure precise winding solutions and advanced filling and welding systems, crucial for optimal performance.

du

Pouch Cell Assembly

Leveraging the Group's extensive experience in pouch solutions, IMA EV-TECH offers process technologies that combine scalability, precision and speed. Our modular lines are designed to ensure high productivity and optimize assembly quality with cutting-edge welding and control systems.

du

Module and Pack Assembly

IMA EV-TECH offers turnkey solutions for every stage of the production process, from assembly to testing and system integration. Customized platforms integrate battery cell inspection and grading with module/pack assembly, supported by robotic systems and digital platforms to enhance efficiency and innovation.

du

Innovative Concepts

- Hybrid systems that combine hybrid, continuous and index-motion processes.

- Integration of multiple processes into a modular platform.

- Minimal product manipulation throughout the manufacturing flow.

- Up to a 50% reduction in space needed for clean and dry rooms.

- High reduction of cost of ownership.

EV-Traction

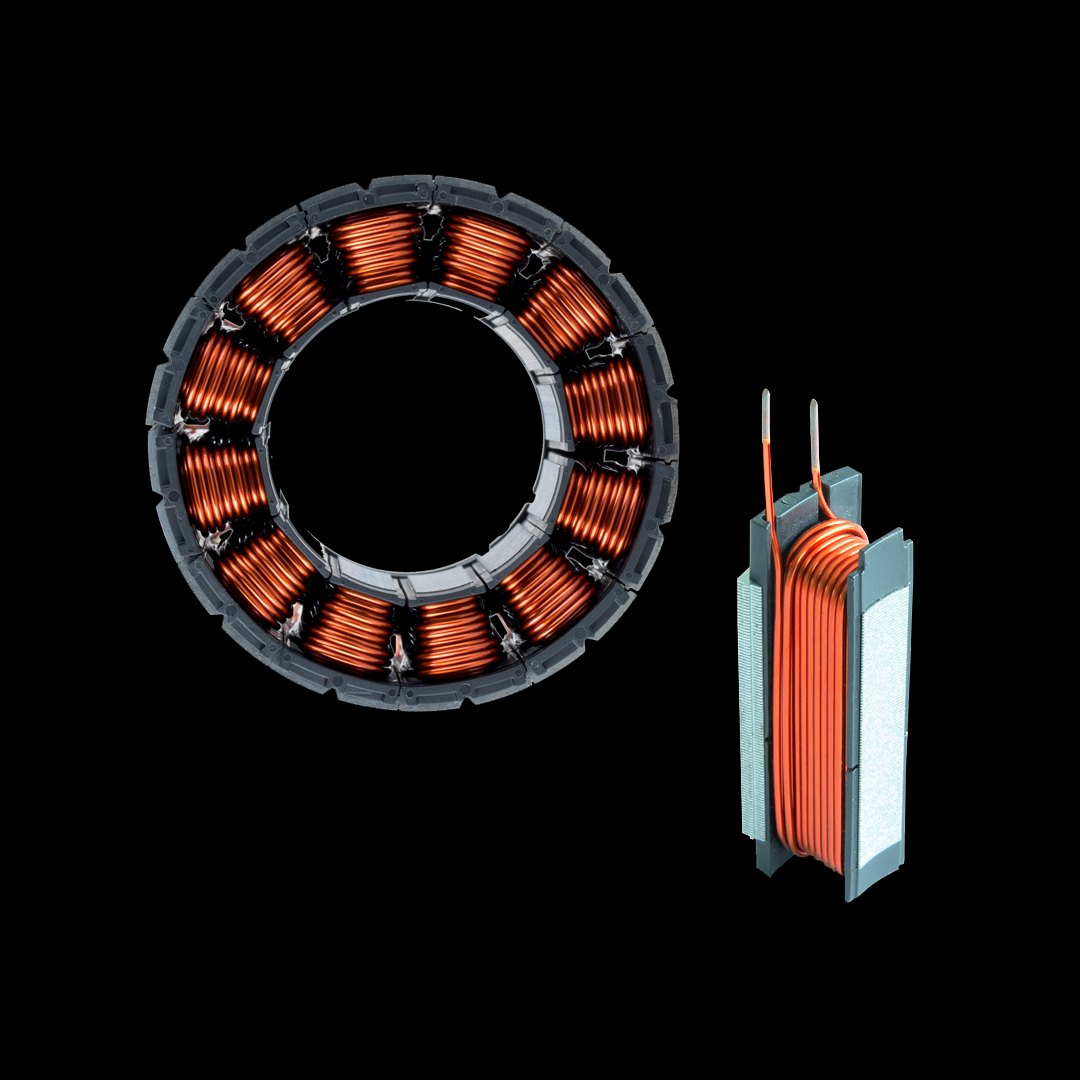

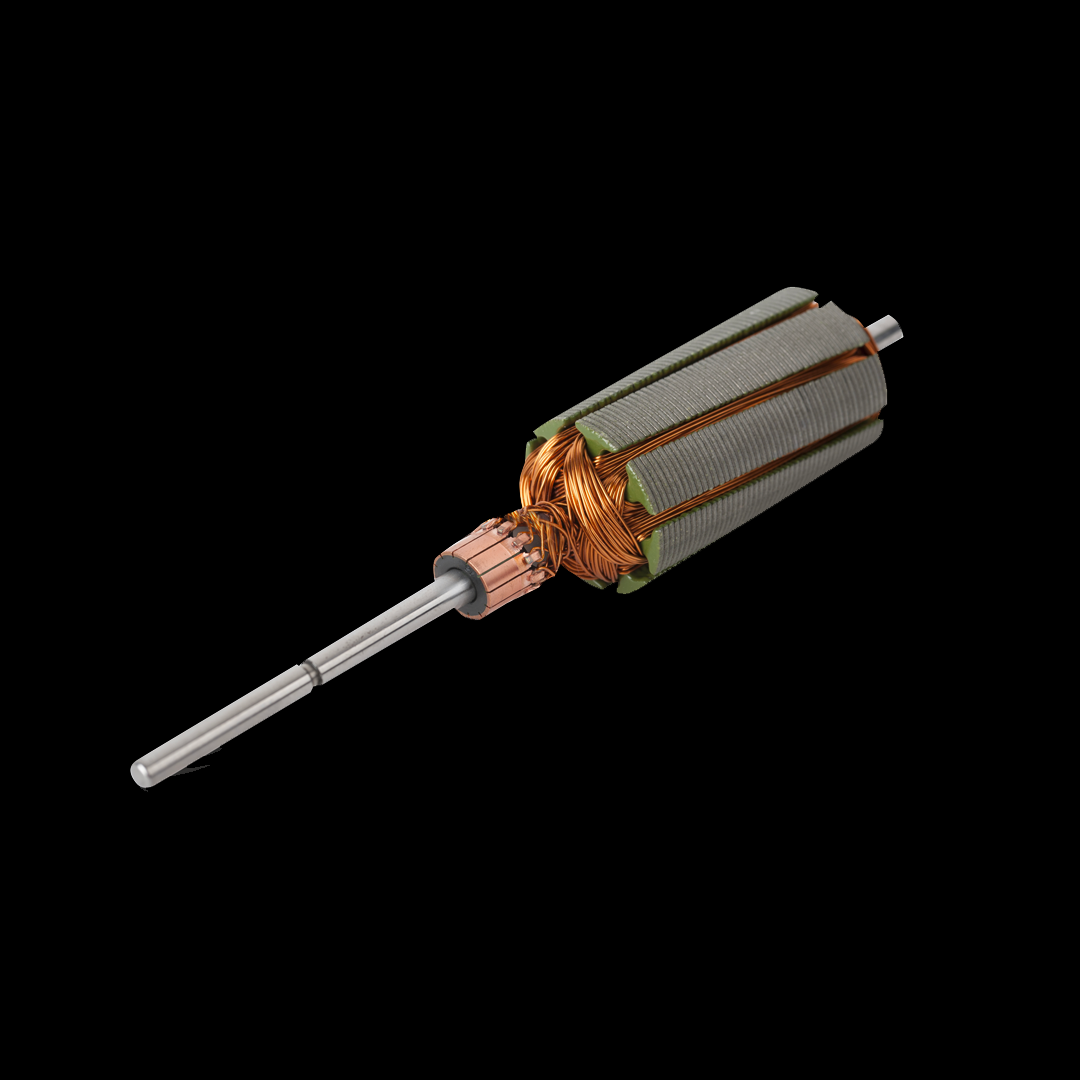

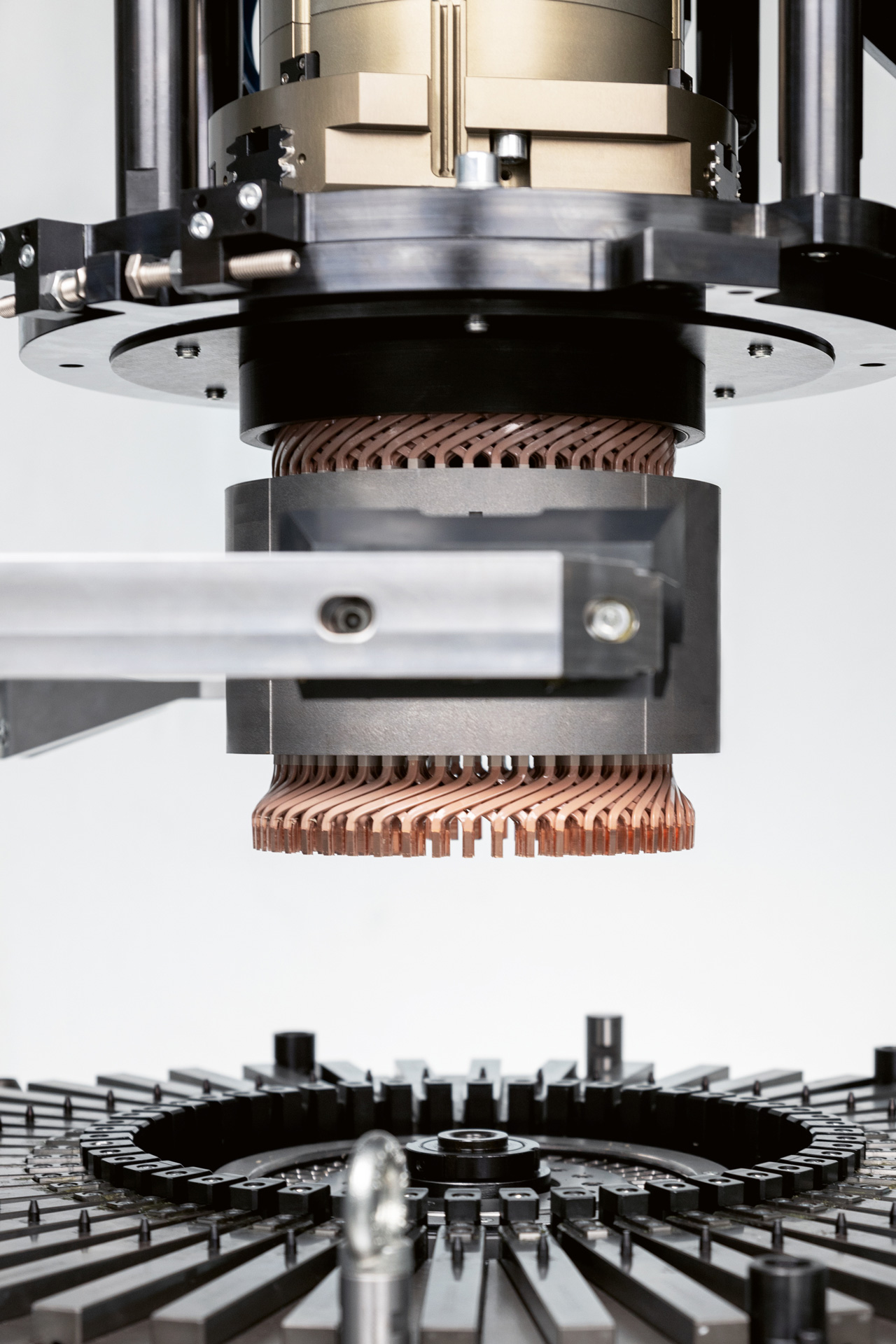

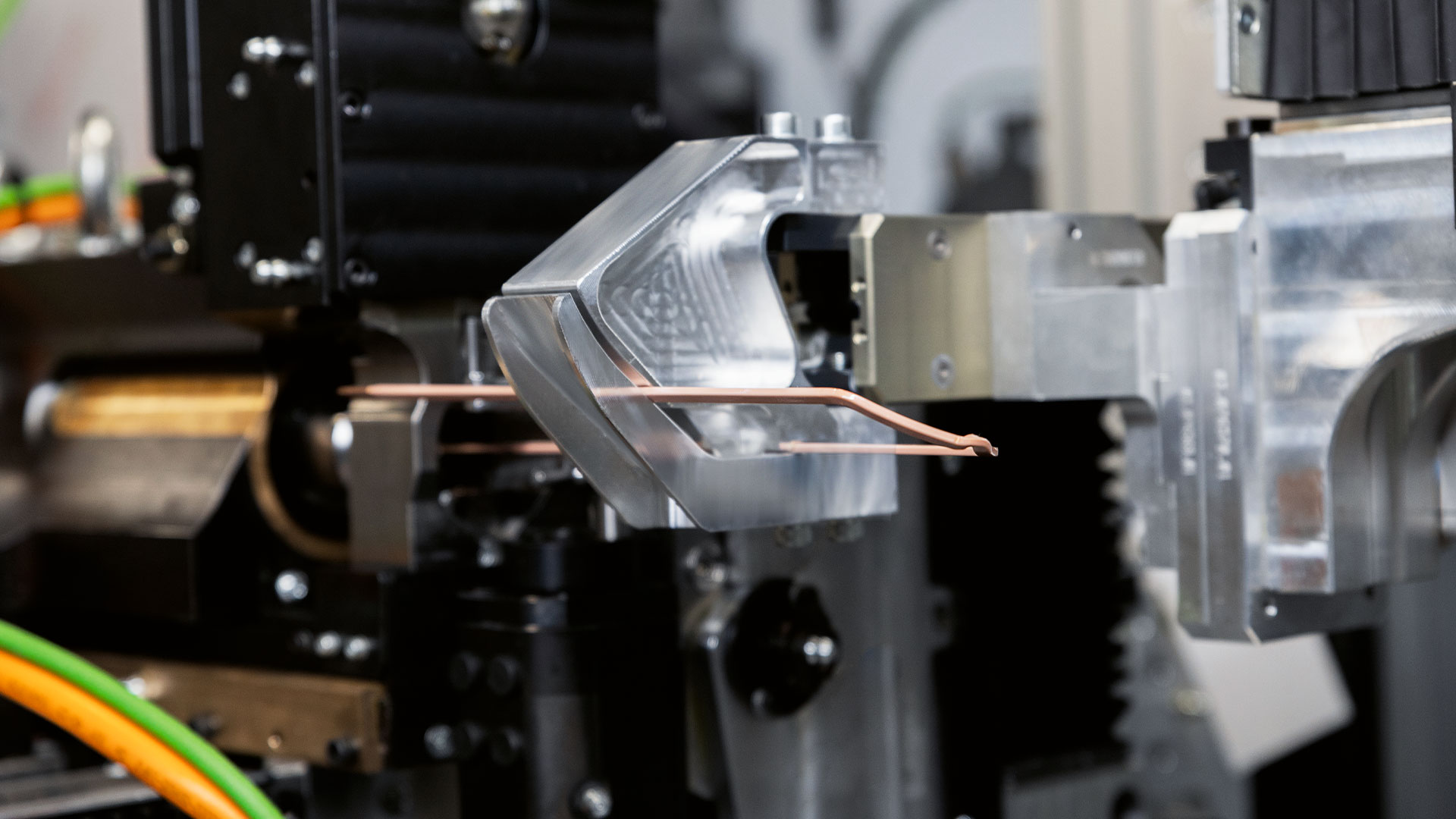

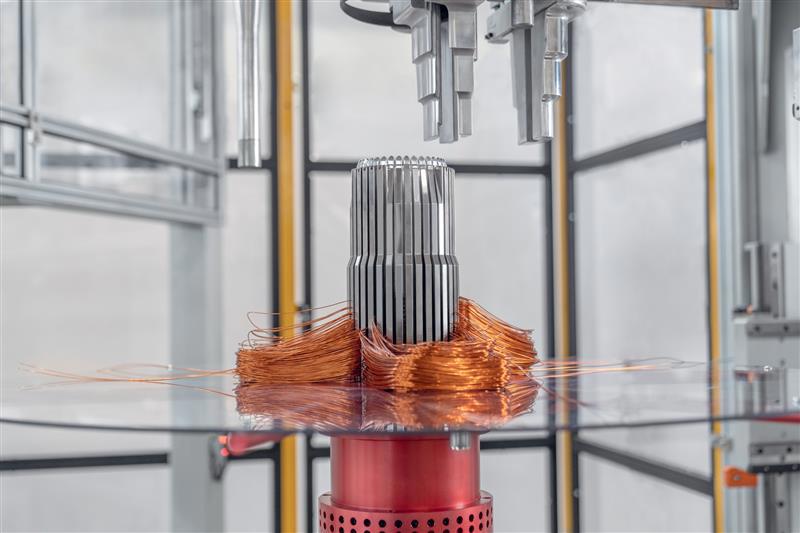

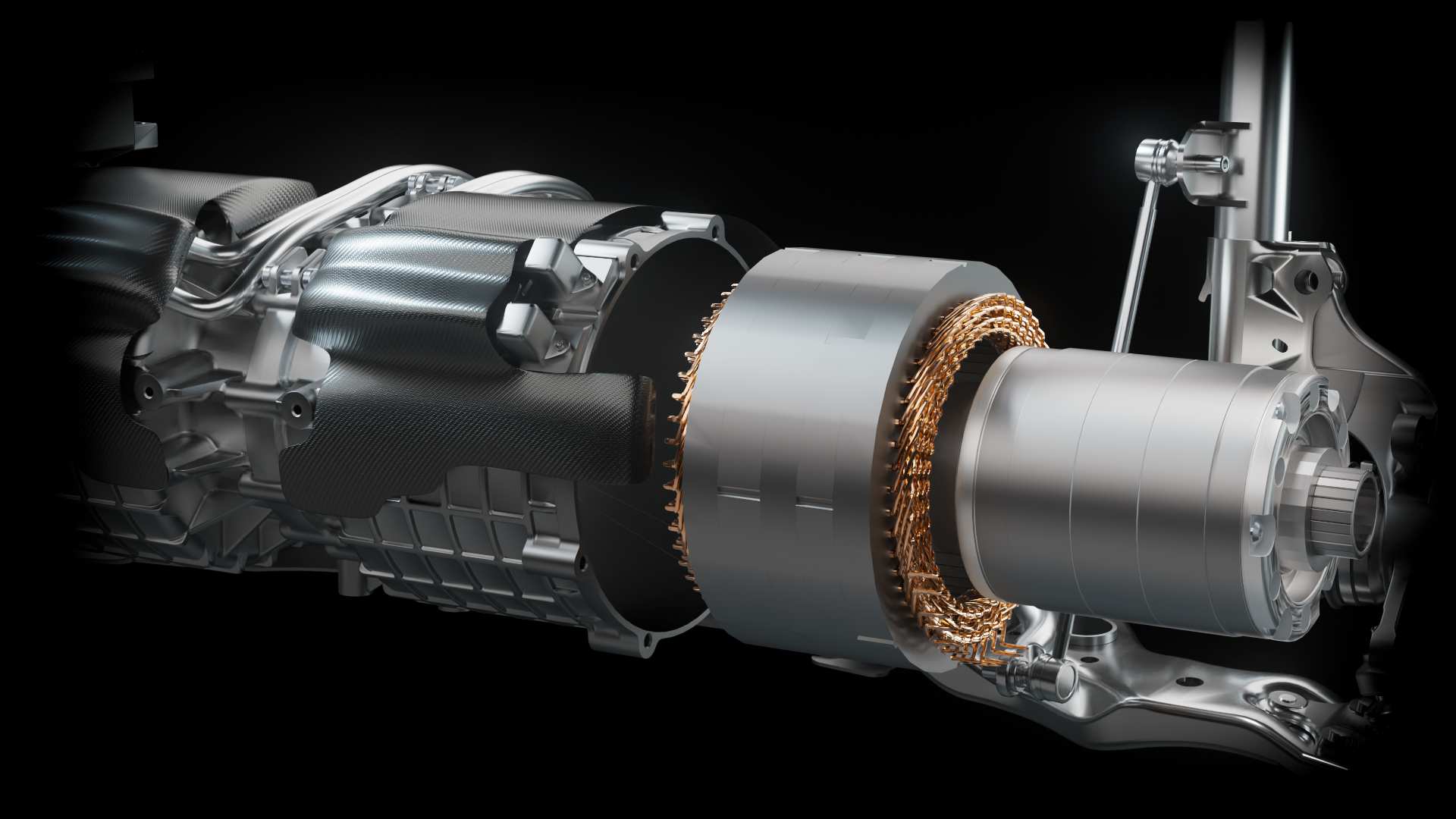

Stator and rotor

Advanced technology solutions for large scale production of stators for traction electric motors.

A consolidated know-how in rotor assembly solutions to meet specific customer requests, even the most complex.

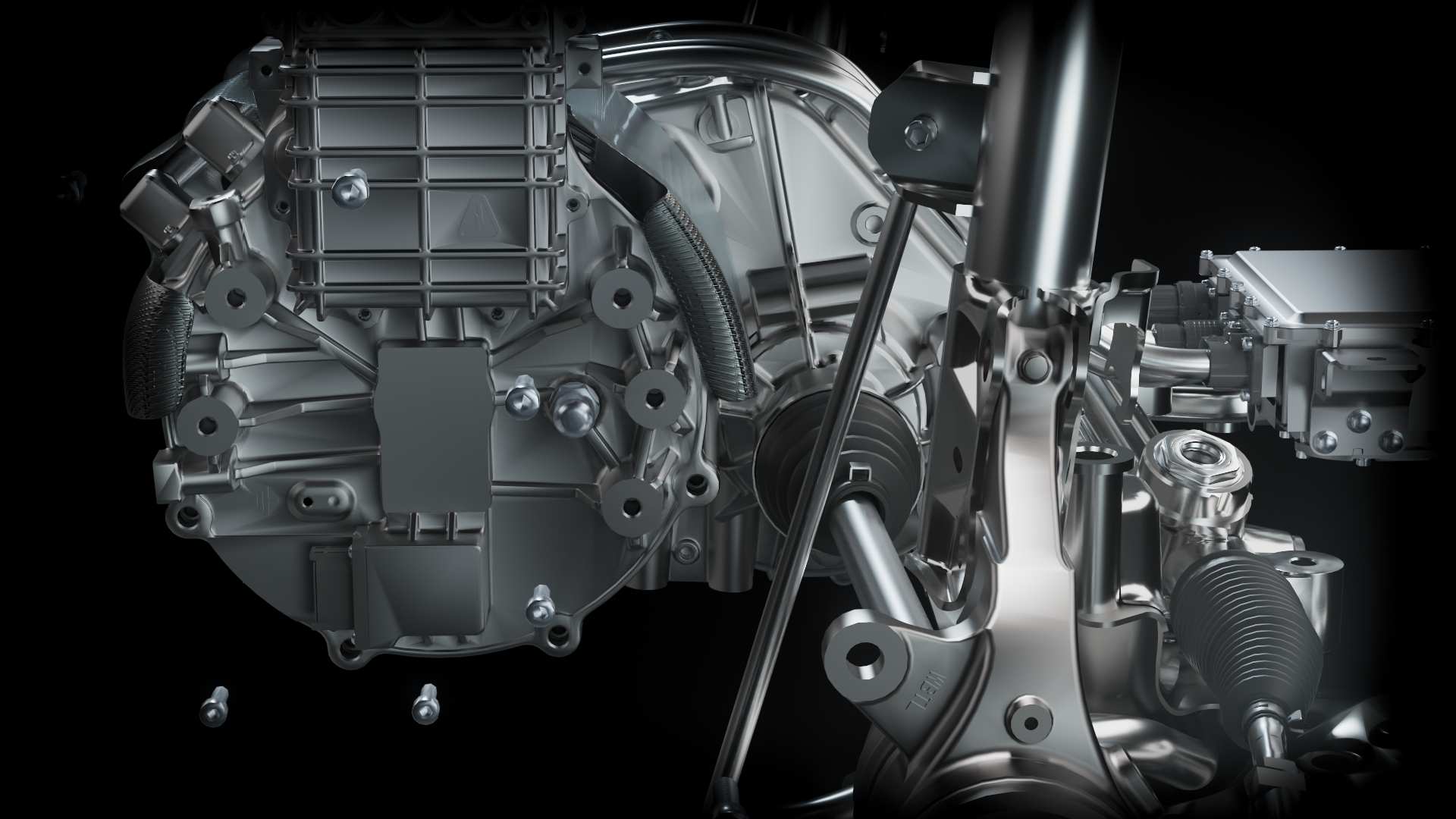

Transmission assembly

Highly flexible lines capable of manage extremely complex transmission components. The drive system is assembled with innovative and customized technological solutions.

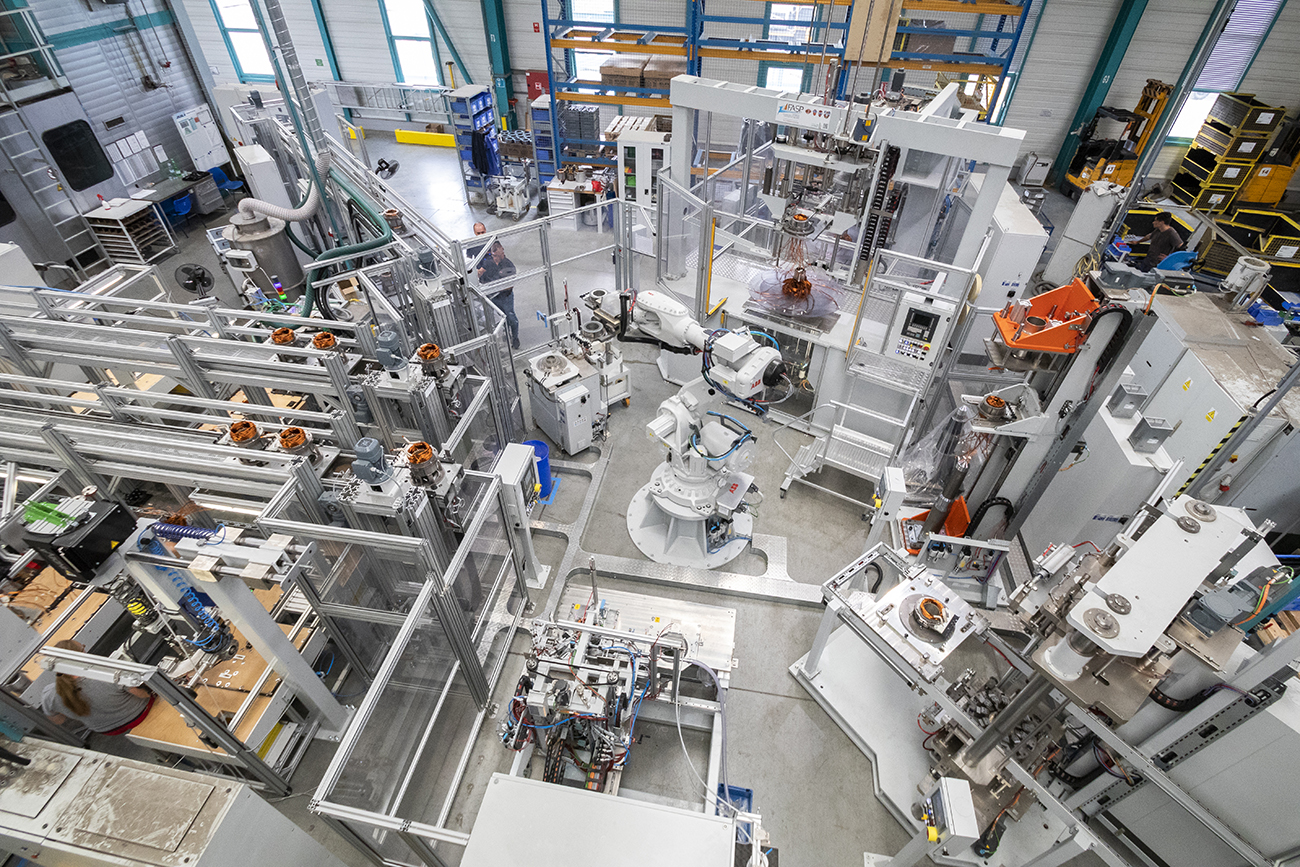

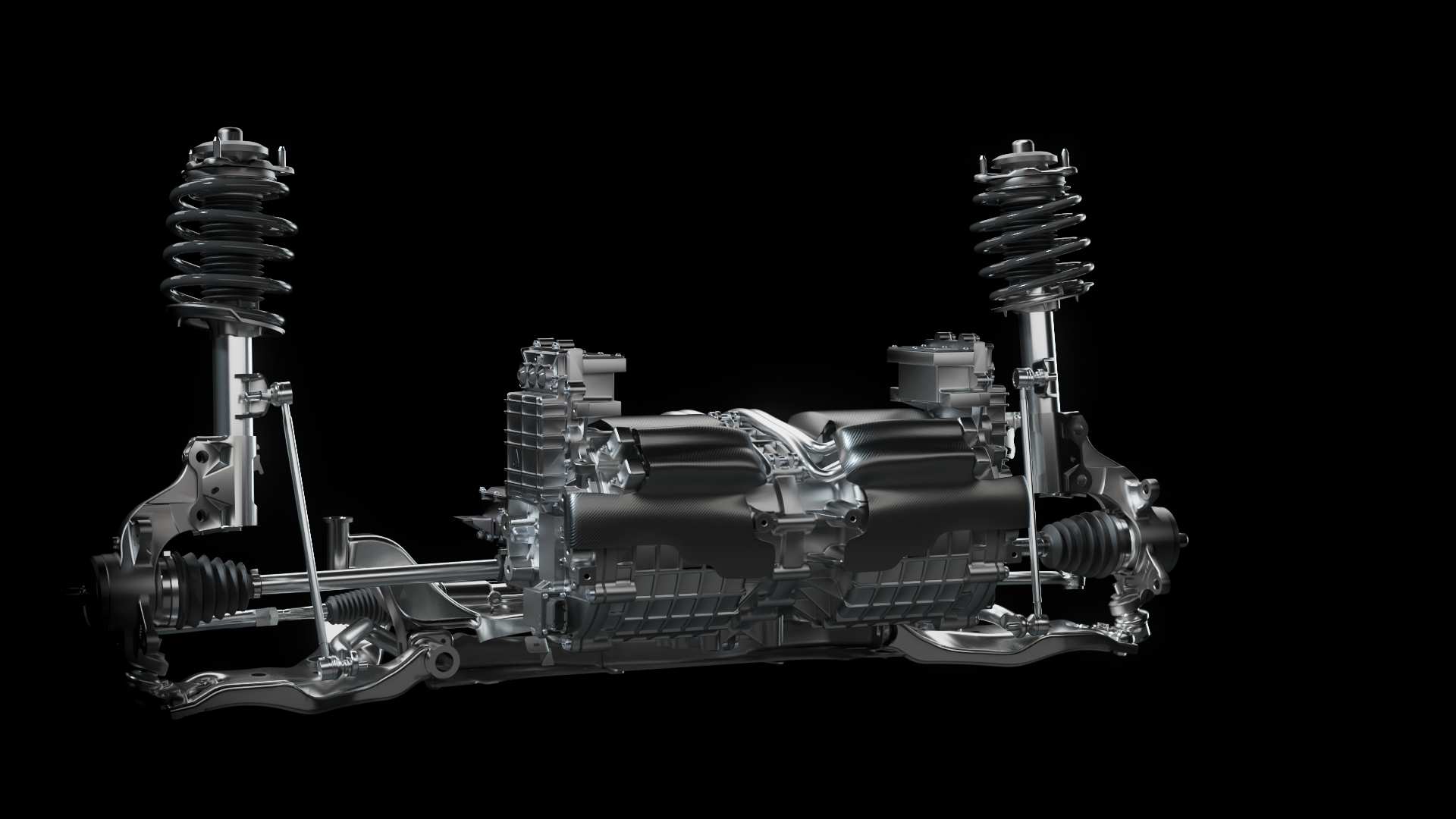

E-Motors assembly

Cutting-edge and modulated technology for the E-motor final assembly. Fully automatic and integrated system solutions with rotor and stator production lines.

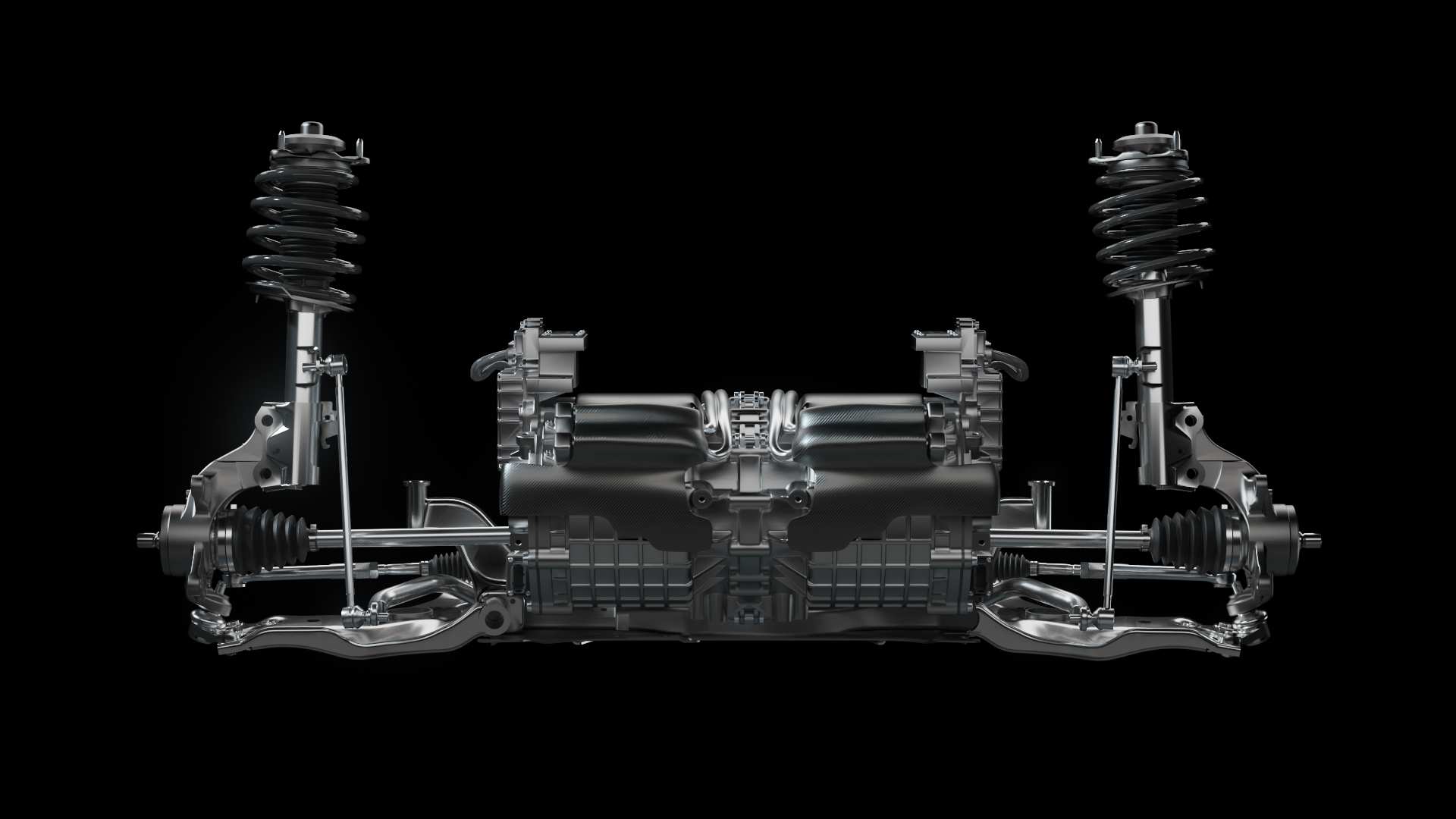

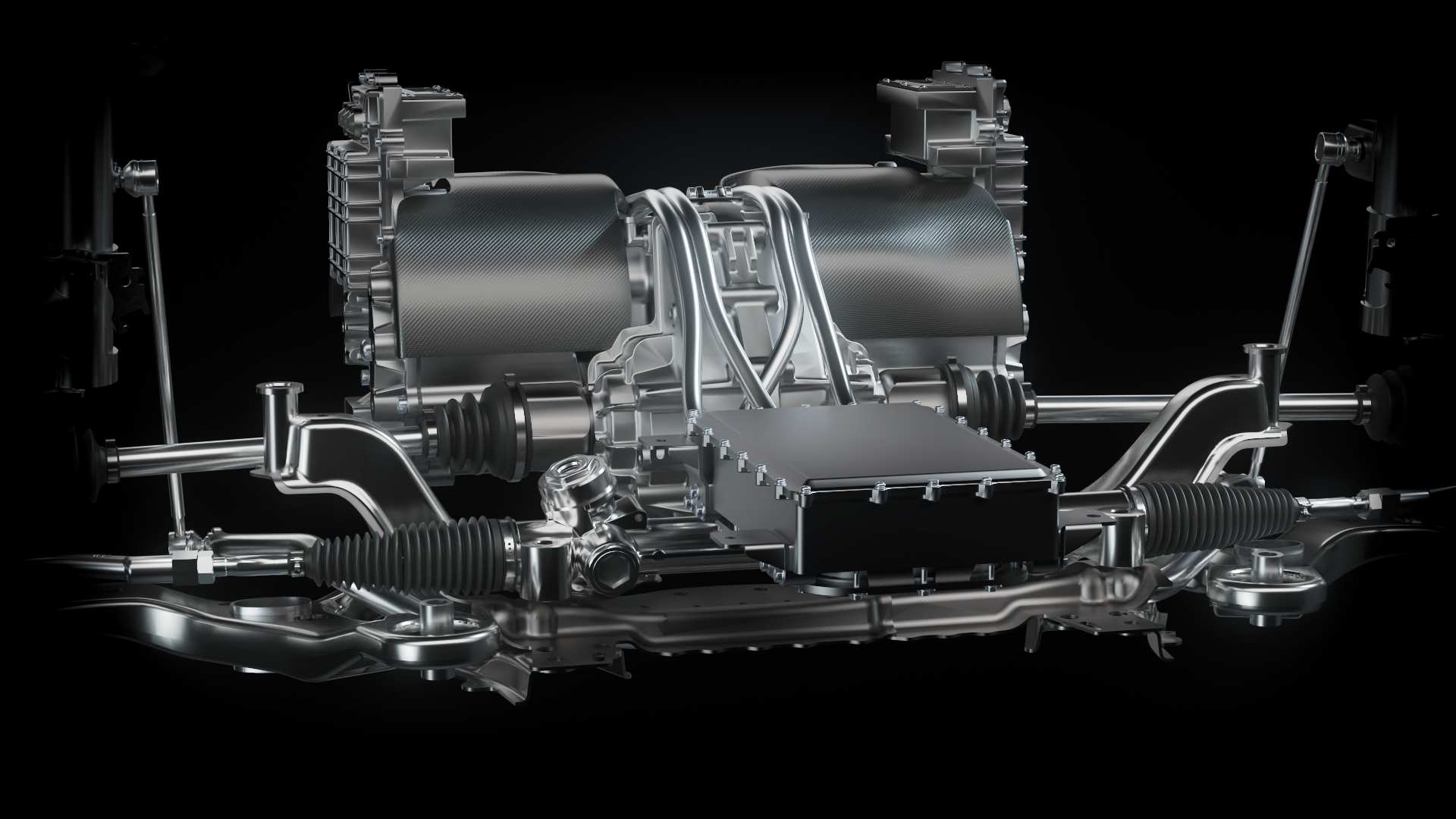

E-Axle assembly

While covering the full spectrum of technologies, IMA EV-TECH is your strategic partner for the E-Axle assembly, integrating e-motor, transmission and power electronics into a single highly performing solution. Tailored technologies to meet quality and production requirements in all assembly processes.

EV-Traction

du

Stator and rotor

Advanced technology solutions for large scale production of stators for traction electric motors.

A consolidated know-how in rotor assembly solutions to meet specific customer requests, even the most complex.

du

Transmission assembly

Highly flexible lines capable of manage extremely complex transmission components. The drive system is assembled with innovative and customized technological solutions.

du

E-Motors assembly

Cutting-edge and modulated technology for the E-motor final assembly. Fully automatic and integrated system solutions with rotor and stator production lines.

du

E-Axle assembly

While covering the full spectrum of technologies, IMA EV-TECH is your strategic partner for the E-Axle assembly, integrating e-motor, transmission and power electronics into a single highly performing solution. Tailored technologies to meet quality and production requirements in all assembly processes.

du

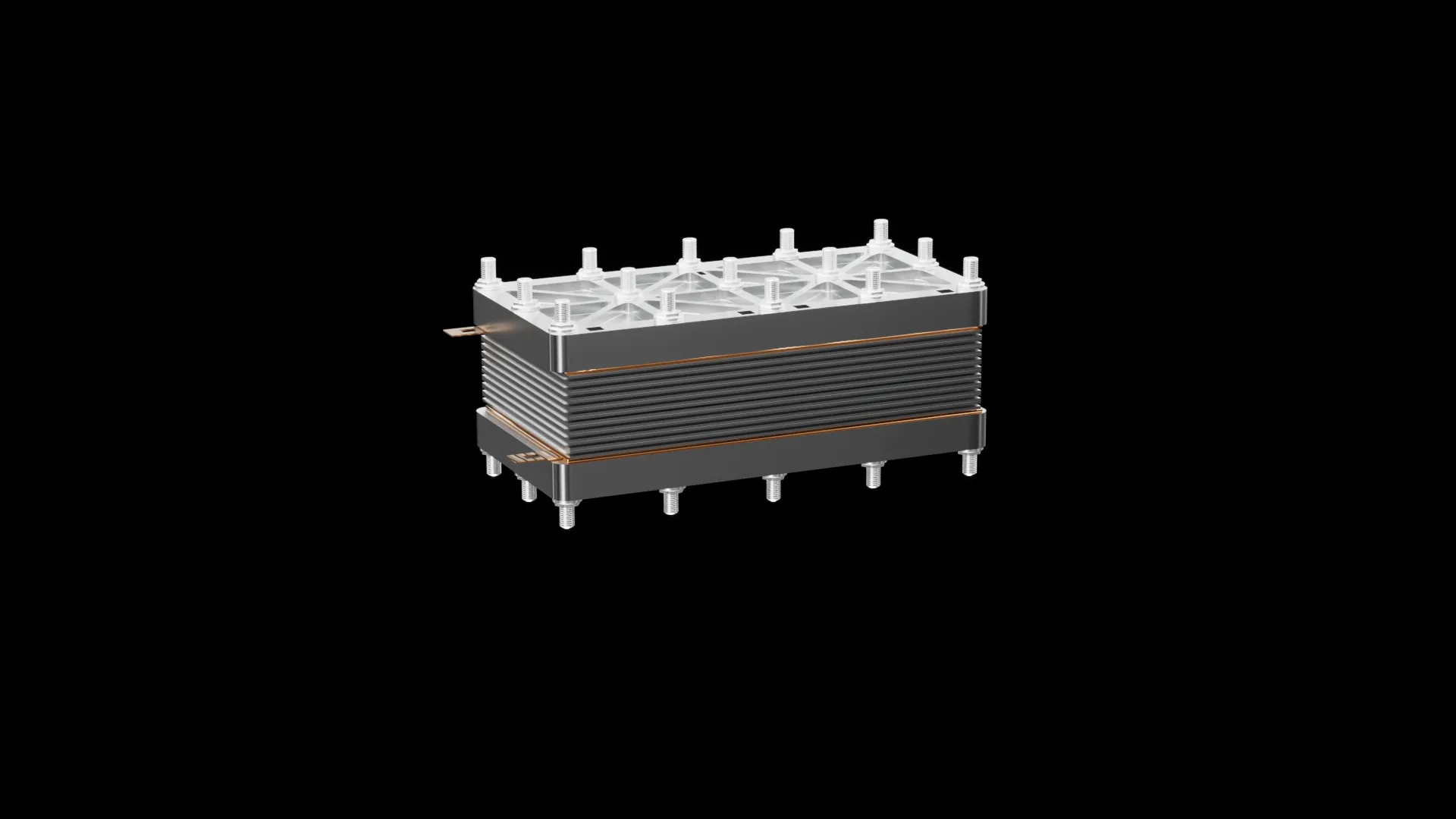

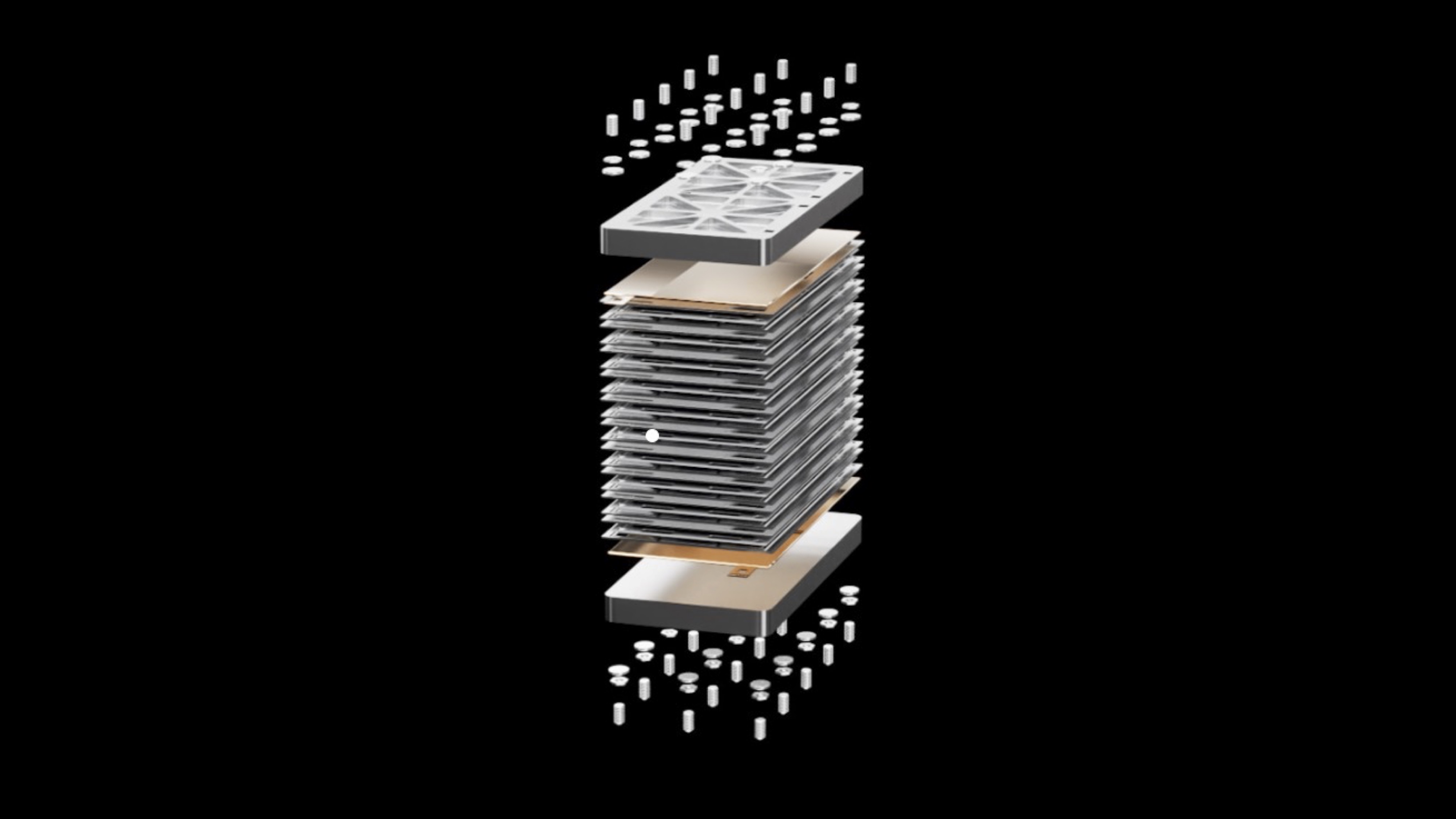

Fuel Cells

Powering Hydrogen Innovation

IMA EV-TECH provides a comprehensive range of technical solutions for the hydrogen fuel cell assembly sector. Our expertise includes the development of machines and assembly lines for membrane-electrode assemblies, stack and system production to meet the evolving demands of the fuel cell industry.

Membrane-Elecrocode Assemblies

IMA EV-TECH solutions are designed to handle critical components in the hydrogen fuel cell assembly process, including the polymer electrolyte membrane (PEM), gas diffusion layer (GDL), and catalyst-coated membrane (CCM), comprising the anode, membrane, and cathode layers.

Fuel Cells

du

Powering Hydrogen Innovation

IMA EV-TECH provides a comprehensive range of technical solutions for the hydrogen fuel cell assembly sector. Our expertise includes the development of machines and assembly lines for membrane-electrode assemblies, stack and system production to meet the evolving demands of the fuel cell industry.

du

Membrane-Elecrocode Assemblies

IMA EV-TECH solutions are designed to handle critical components in the hydrogen fuel cell assembly process, including the polymer electrolyte membrane (PEM), gas diffusion layer (GDL), and catalyst-coated membrane (CCM), comprising the anode, membrane, and cathode layers.

du

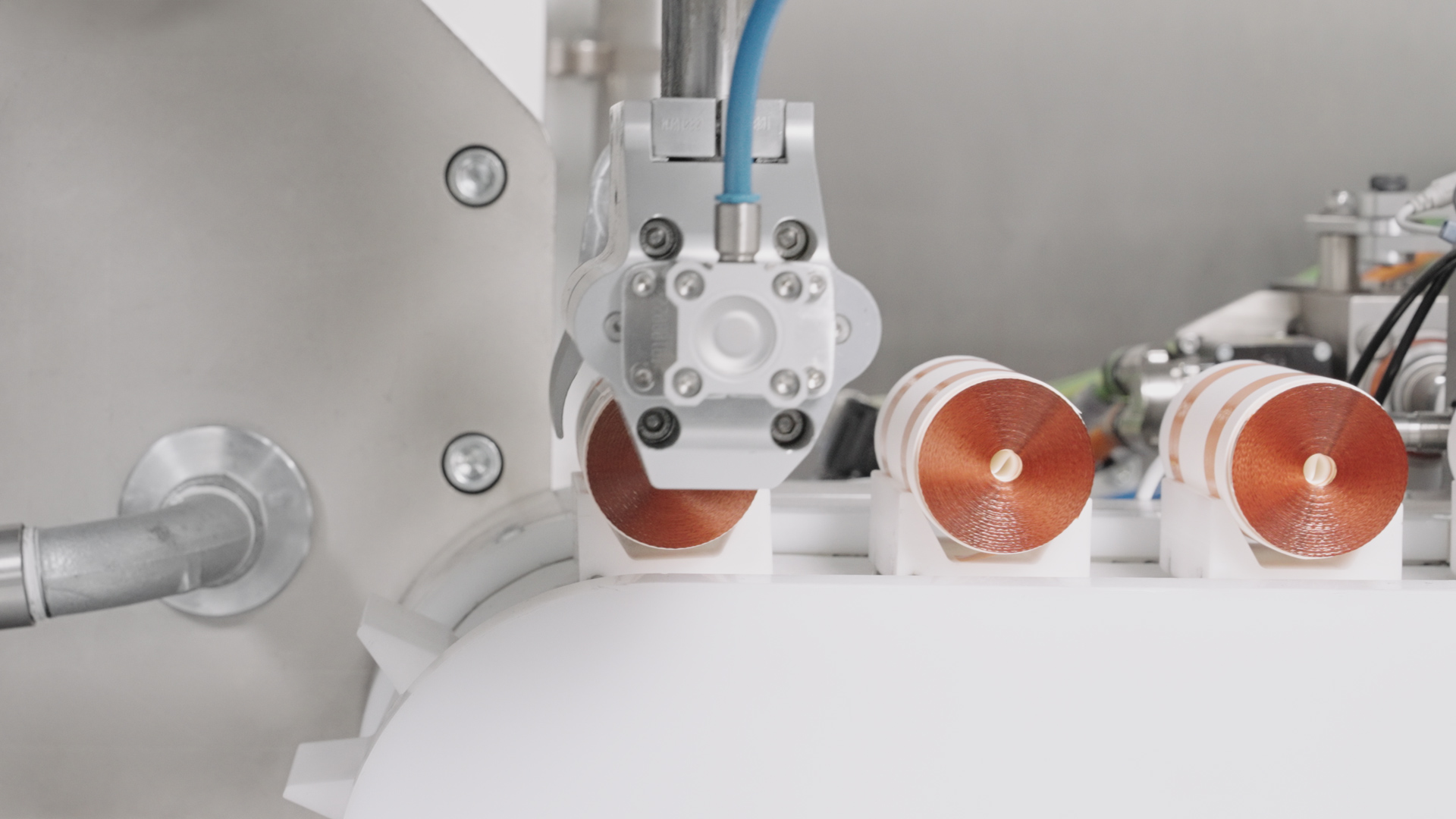

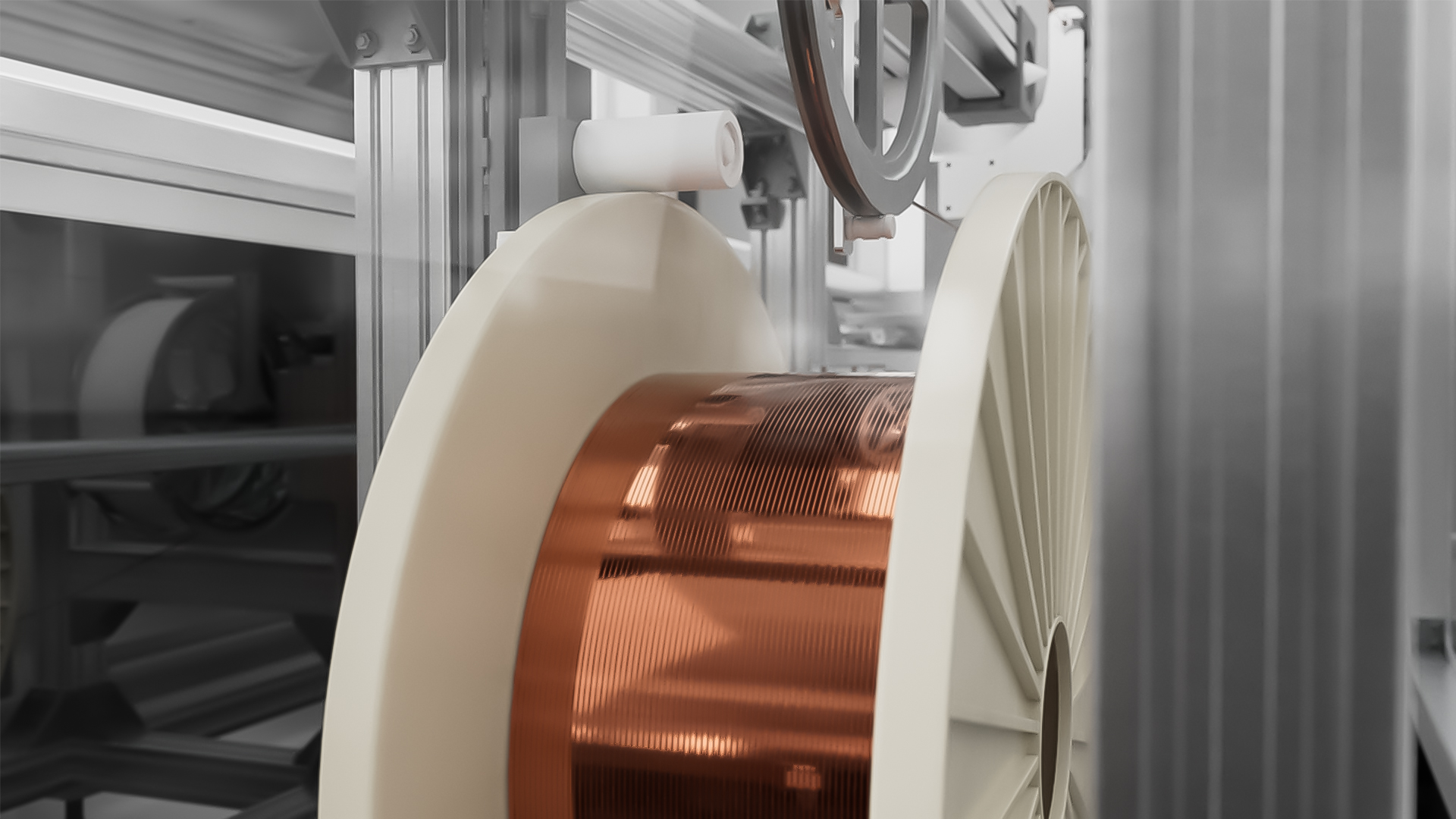

Auxiliary Motors

Tailored Solutions for Auxiliary Motors

IMA EV-TECH, with its extensive experience in winding technologies, specializes in designing and manufacturing cutting-edge automatic lines,for the production of high-precision auxiliary motors, engineered to reduce energy consumption and increase the reliabilityof electric vehicles.

Auxiliary Motors

du

Tailored Solutions for Auxiliary Motors

IMA EV-TECH, with its extensive experience in winding technologies, specializes in designing and manufacturing cutting-edge automatic lines,for the production of high-precision auxiliary motors, engineered to reduce energy consumption and increase the reliabilityof electric vehicles.

du

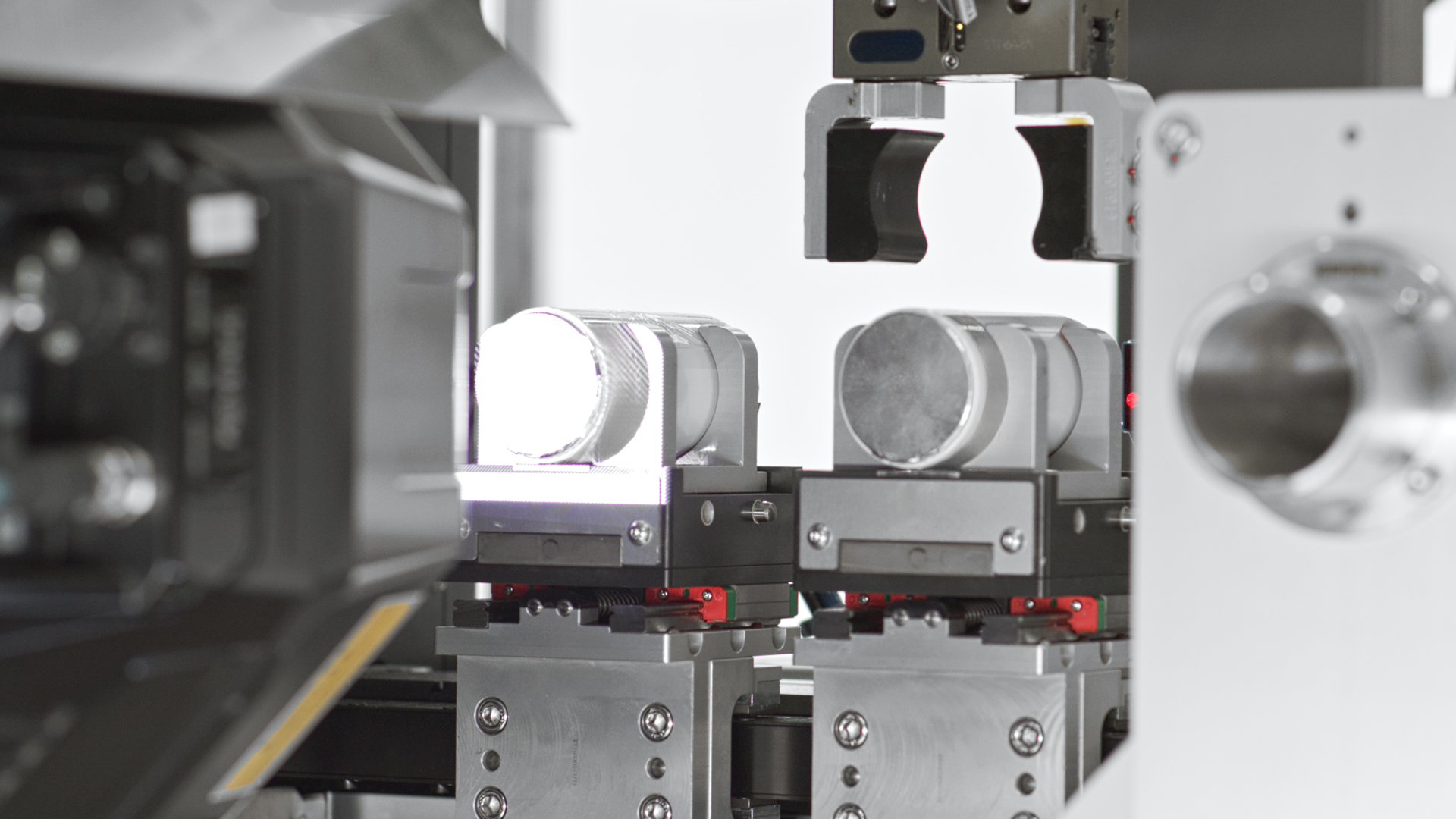

Technologies

Check

latest news

Exhibitions

Locations

IMA EV-TECH is composed of leading companies in the assembly industry, with over 60 years of experience, which design and manufacture advanced technology solutions for handling and assembling parts for different application fields. With six manufacturing plants, IMA EV-TECH integrated network of companies guarantees a worldwide coverage and a unique excellent offer, regardless of where the lines is realized.

Via Kennedy, 17 - Via Parini, 1

Zola Predosa, 40069

Bologna | Italy

Strada S. Appiano, 8/A

Barberino Tavarnelle, 50028

Firenze | Italy

Via Chemello, 22

Montecchio Maggiore, 36075

Vicenza | Italy

Tianyi Road, Building 1,

No 605 - 607,

Qingpu District, 201712

Shanghai | China