EOL Packaging & Cleaning System

This state-of-the-art system revolutionises the final stages of battery cell production, offering comprehensive inspection,

cleaning, and packaging capabilities. Designed with a focus on quality, efficiency, and automation, this system ensures that only the highest quality cells reach your customers.

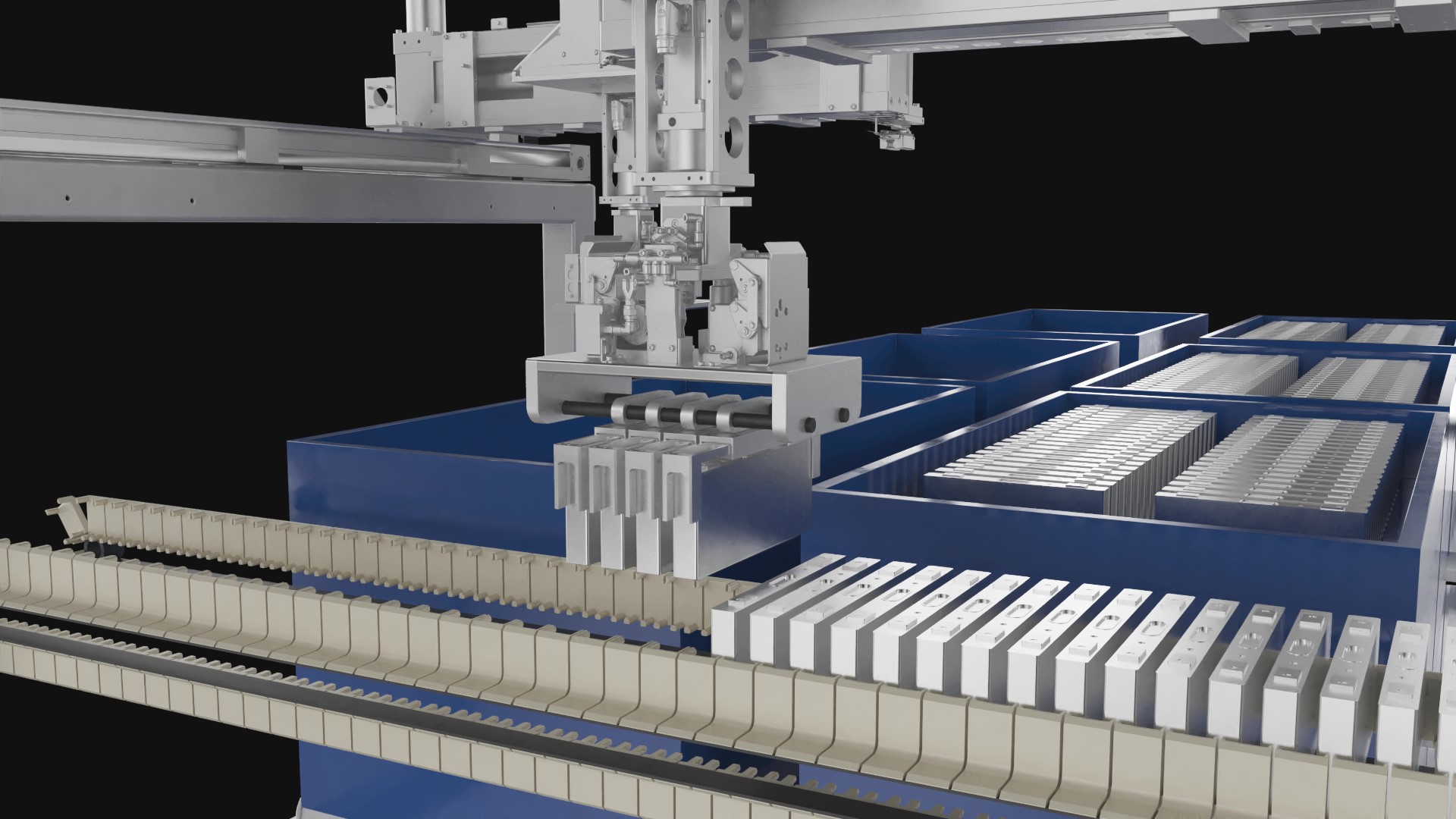

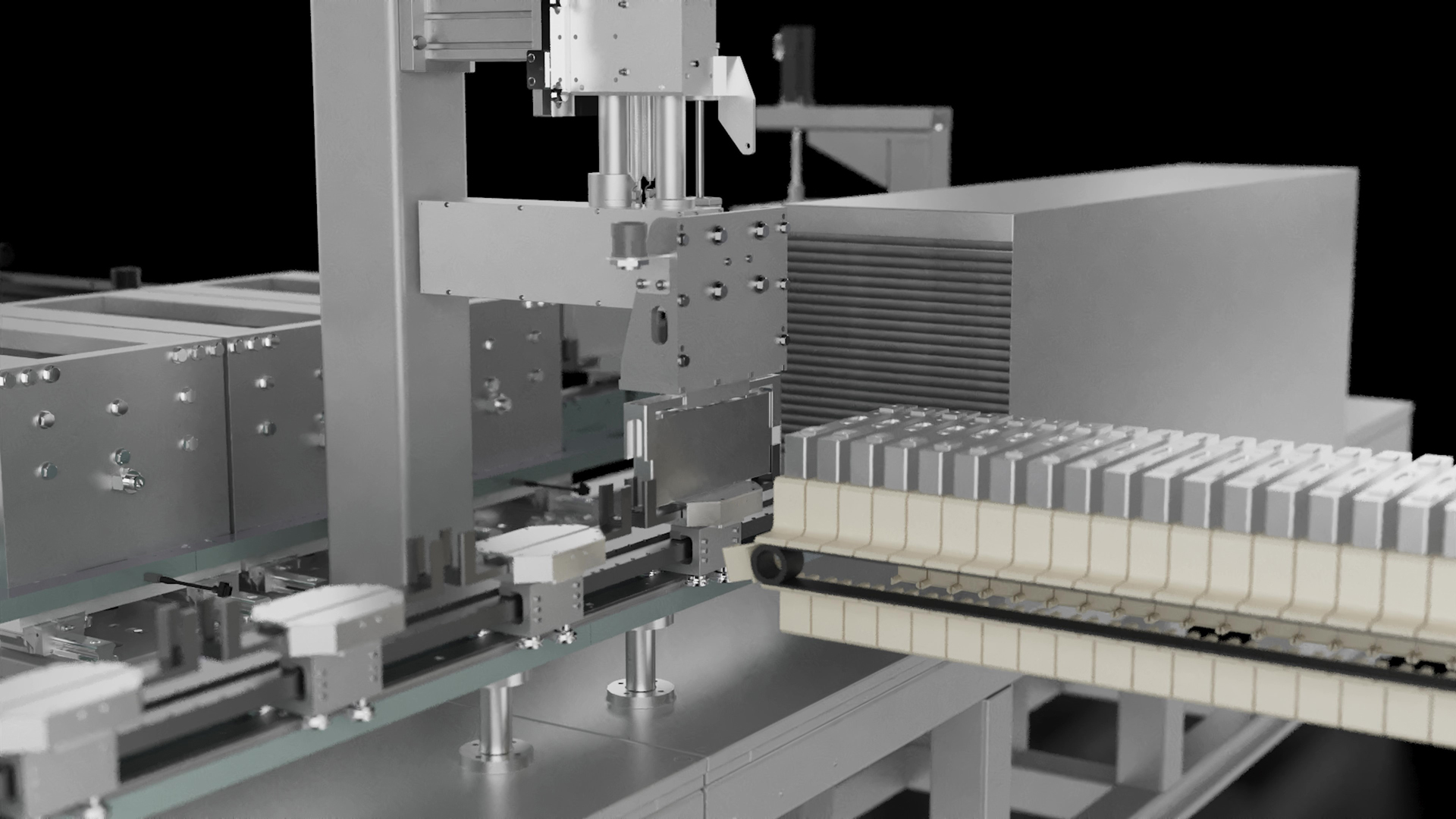

Intelligent Cell Handling and Transport

This system seamlessly transports cells through each stage of the process, minimizing handling time and reducing the risk of damage. It utilizes a network of conveyors, linear carriers, and gantry robots to efficiently move cells between stations, while a delicate gripping mechanism ensures quality by supporting edges without applying harmful pressure. An advanced anti-collision system, combining vision systems, sensors, and motor torque control, further safeguards cells during handling.

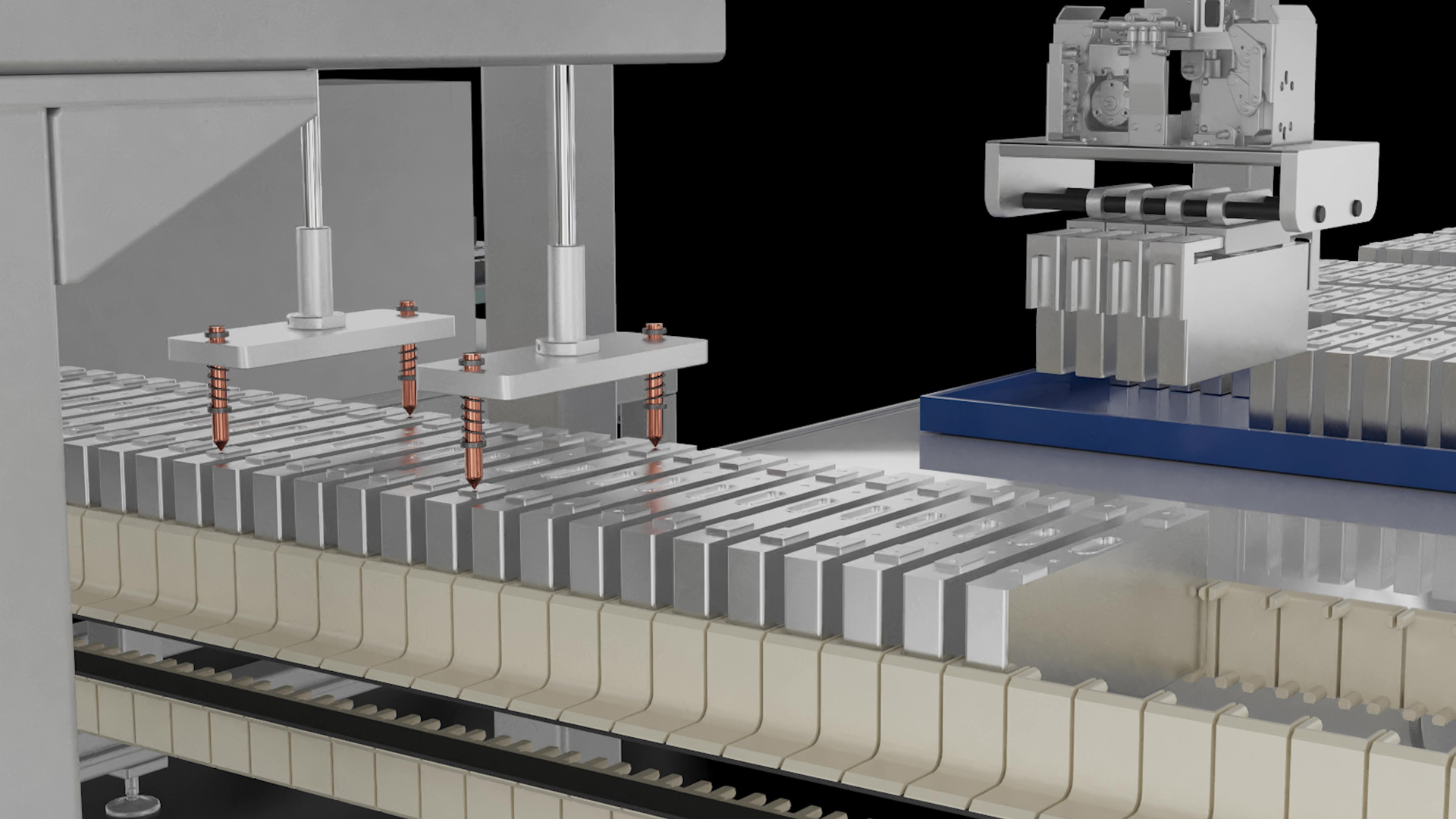

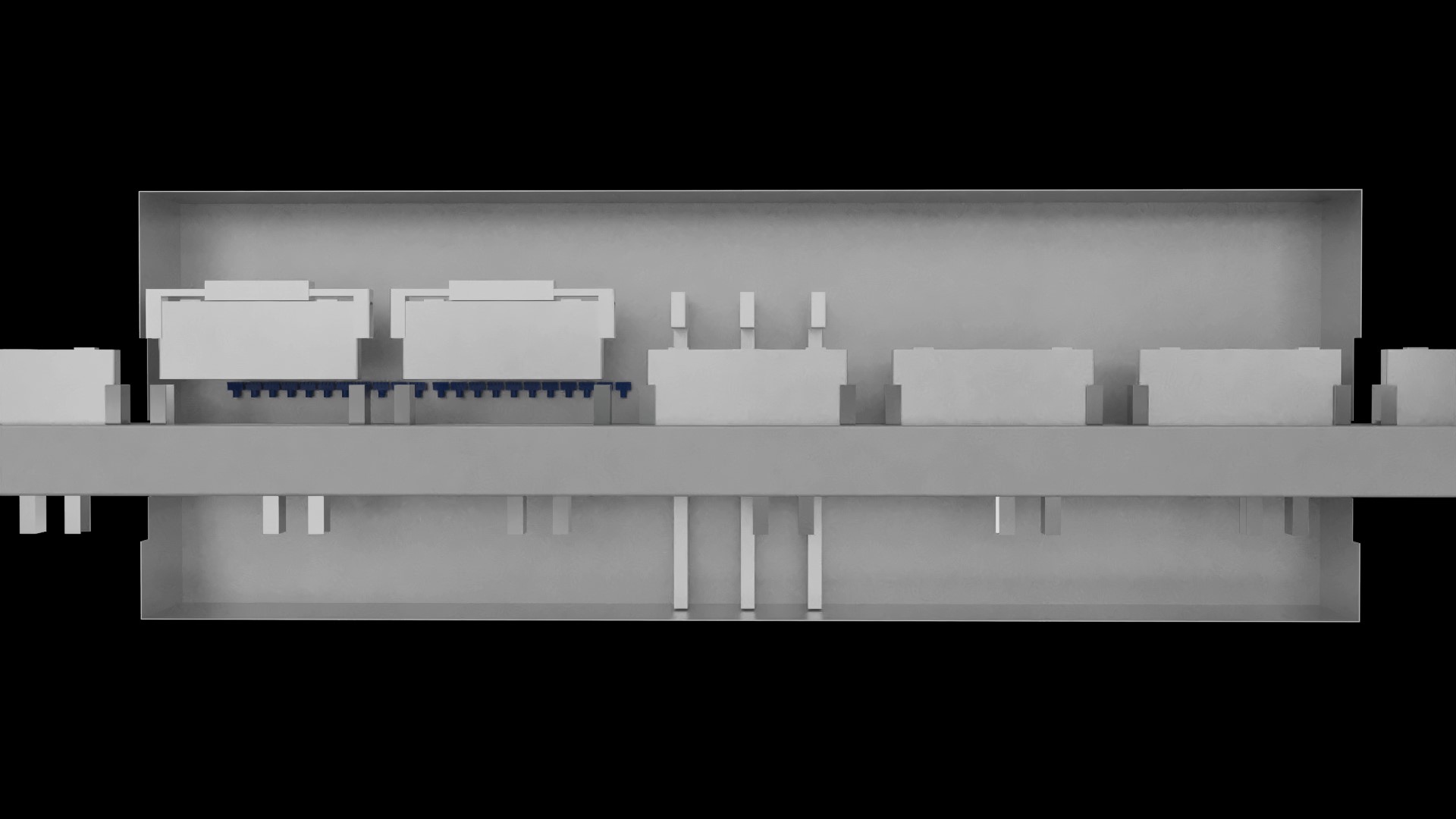

Comprehensive Cell Inspection

Rigorous inspection protocols guarantee that every cell meets the highest quality standards, minimizing the risk of defects and ensuring optimal performance. The system achieves this through a network of specialized inspection stations, each designed to evaluate different aspects of cell quality:

- Cell ID Inspection: Each cell's ID is scanned using a QR code reader to ensure proper tracking and traceability.

- Electrical Inspection (ACIR/OCV): High-precision testers measure AC internal resistance (ACIR) and open-circuit voltage (OCV), identifying potential electrical defects. De-ionised air flow cleans terminals before testing to ensure accurate measurements.

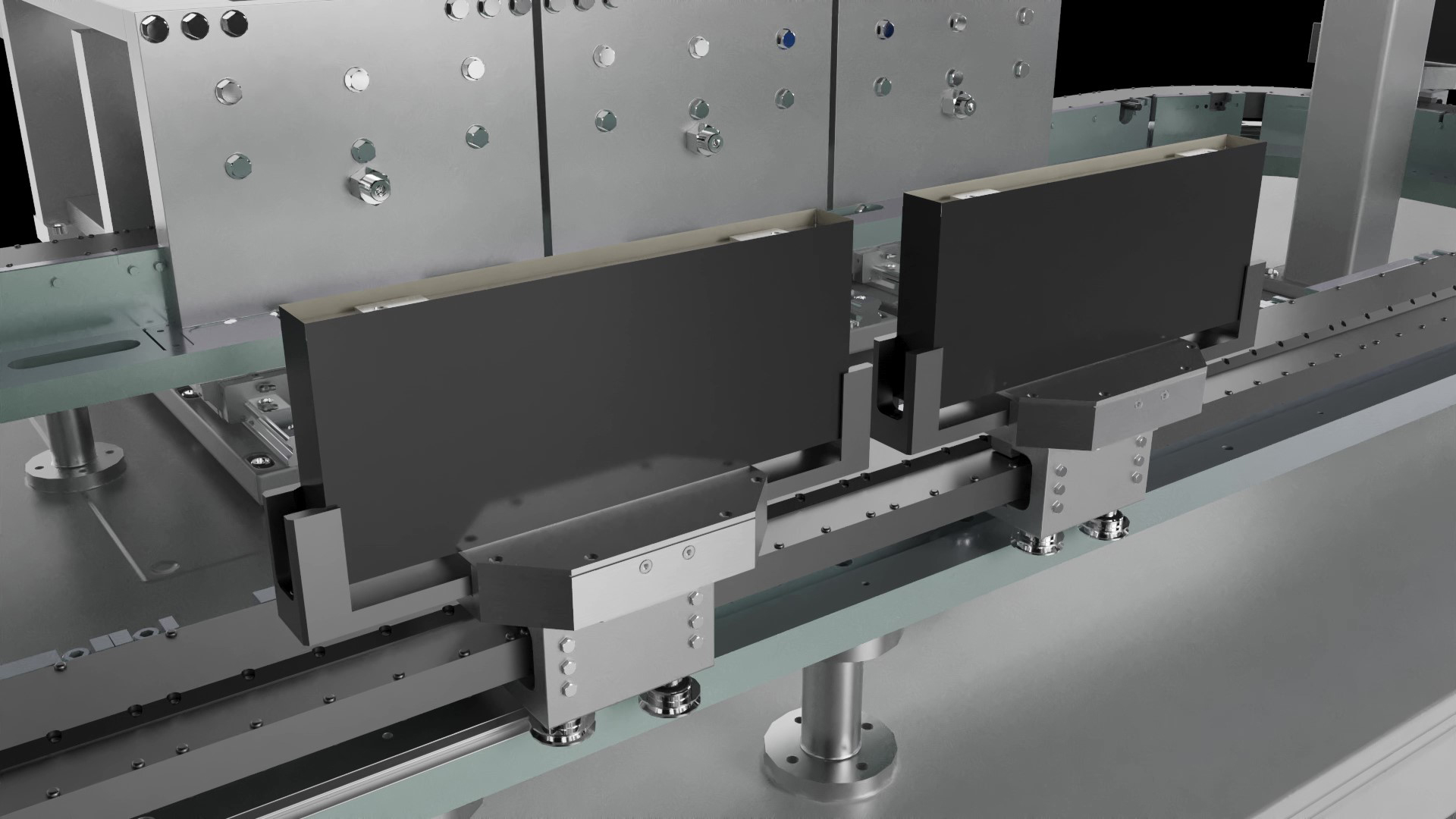

- Dimension Checks: Non-contact sensors precisely measure cell length, width, and thickness, ensuring dimensional accuracy.

- Compression Test: Horizontal electrical presses apply controlled compression force to assess cell robustness and structural integrity.

- Hi-Pot Insulation Test: Hi-Pot testers apply high voltage to check insulation resistance, ensuring electrical safety.

- Weight Check: High-accuracy scales measure cell weight, identifying any deviations from specified tolerances.

- Vision Inspection: Multiple high-speed cameras inspect cell surfaces (bottom, top, front, back, and sides) for visual defects. The system includes calibration procedures, golden samples, and master blocks to ensure accurate and reliable inspection.

Advanced Cleaning Technologies

Thorough cleaning processes remove contaminants, enhancing cell performance, longevity, and safety. The Cell Cleaning Station employs de-ionized air knives to clean cell surfaces and workpiece carriers, effectively minimizing cross-contamination. Dust collection and filtration systems ensure a consistently clean environment. Additionally, an optional standalone cleaning system is available to clean outbound packaging components, such as bins, lids, and inner layers, eliminating residual contaminants and ensuring the cleanliness of the final packaged product.

Self adhesive film wrapping

Automated processes streamline operations, increase throughput, and ensure consistent, high-quality wrapping. The system features a servo-driven wrapping station that applies a protective film around the cell, securing packaging and minimizing the risk of damage during transport. A plasma micro-fine cleaning system prepares cell edges for optimal tape adhesion, enhancing packaging integrity. Additionally, a heating frame folds and adheres the film's protruding edges securely to the cell's upper surface, further strengthening packaging security.

Automated Non-Conforming Cell Handling

The system efficiently manages non-conforming cells, ensuring that only high-quality cells proceed to packaging while providing valuable data for process improvement. Cells that fail any inspection are automatically diverted to dedicated NC ports, where a gantry robot transfers them to specific drawers based on the type of failure. For additional analysis, the system offers an optional manual visual inspection station, enabling a deeper evaluation of non-conforming cells.