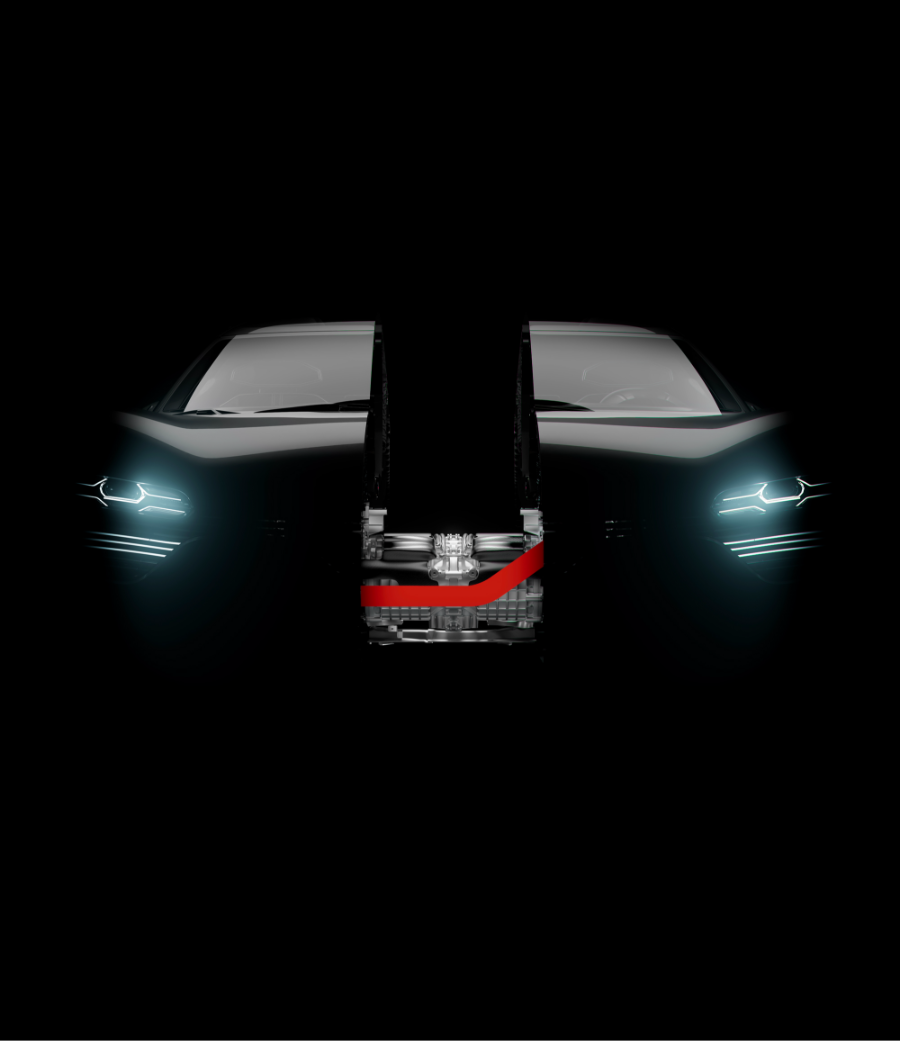

Cylindrical Winding Technology

The High Speed Winder revolutionizes Cylindrical Jelly Rolls manufacturing by combining precision, speed, and advanced automation in a reduced footprint. Each phase is designed to optimize workflow, minimize materials waste, and ensure consistent quality. Thanks to its modular structure and integrated functions, this technology is perfectly suited for any advanced industrial production environment, enabling the production of different product configurations and dimensions, with a linear speed up to 3m/s

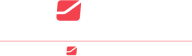

Intelligent Reel Loading and Seamless Splicing

With a motorized reel support system and CPC detection technology, reel loading and material alignment are fast, accurate, and fully automated. The automatic splicing feature joins new reels seamlessly as the previous one nears completion, ensuring uninterrupted production and boosting efficiency. Zero downtime and fully automated reel management reduce manual intervention, increasing productivity and minimizing errors.

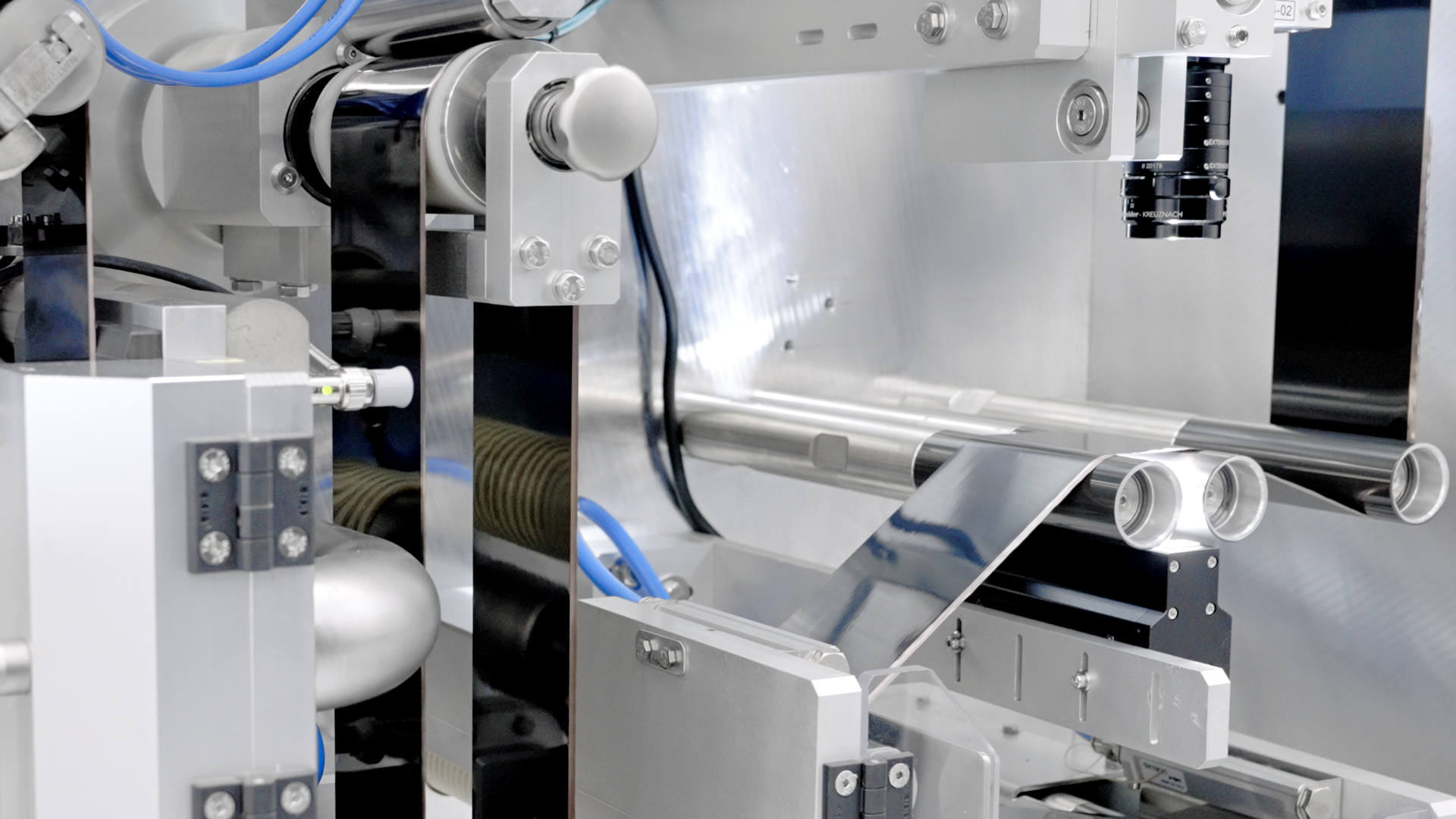

Optimal Materials Tensioning and Positioning

Maintaining ideal tension at every stage, the system’s tensioning unit ensures that the material remains stable and optimally positioned, reducing imperfections and production waste. This continuous control over tension and positioning translates to higher efficiency and consistently high-quality output. Precise tension control minimizes waste and enhances the quality of every single electrode, leading to cost savings and consistent production quality.

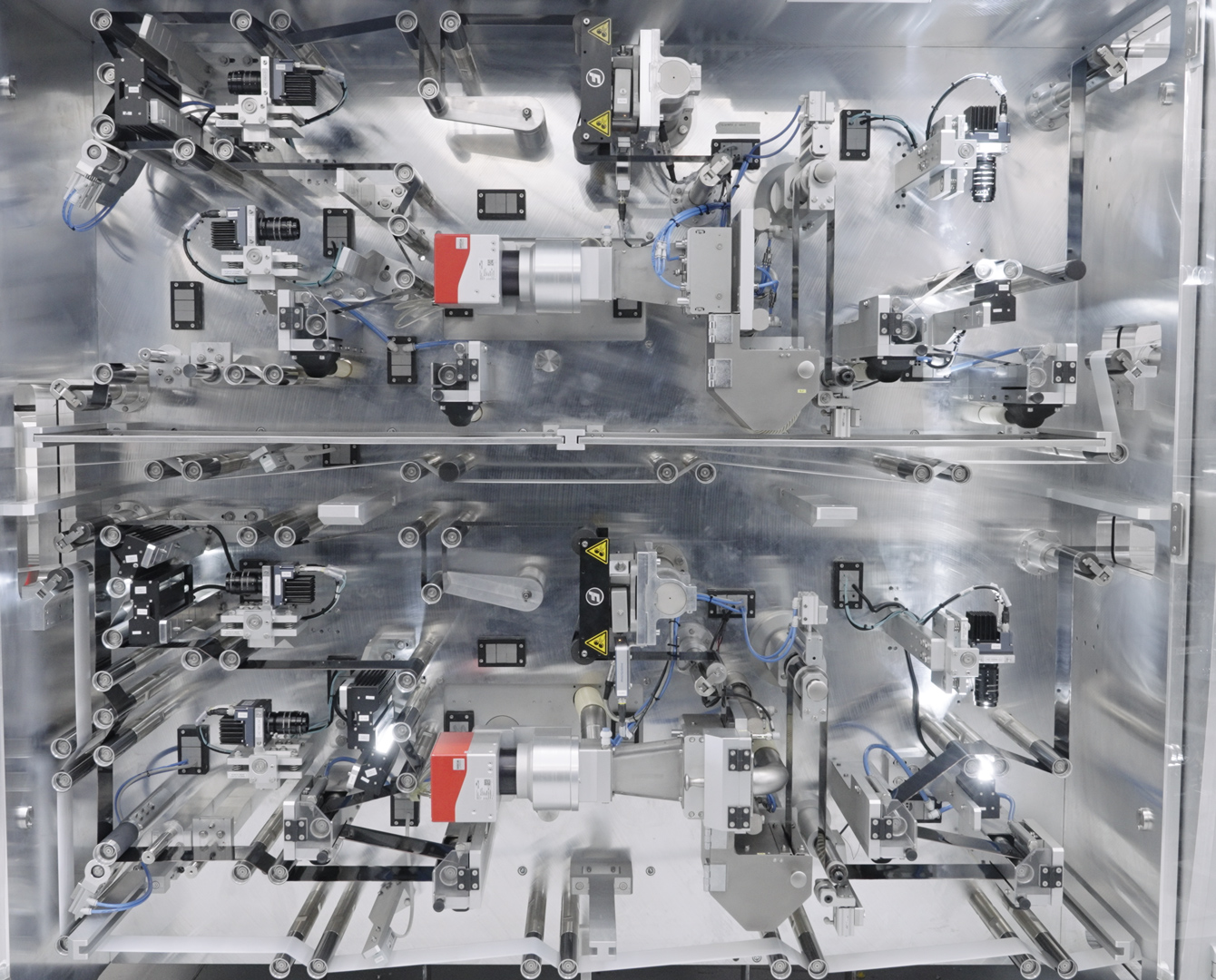

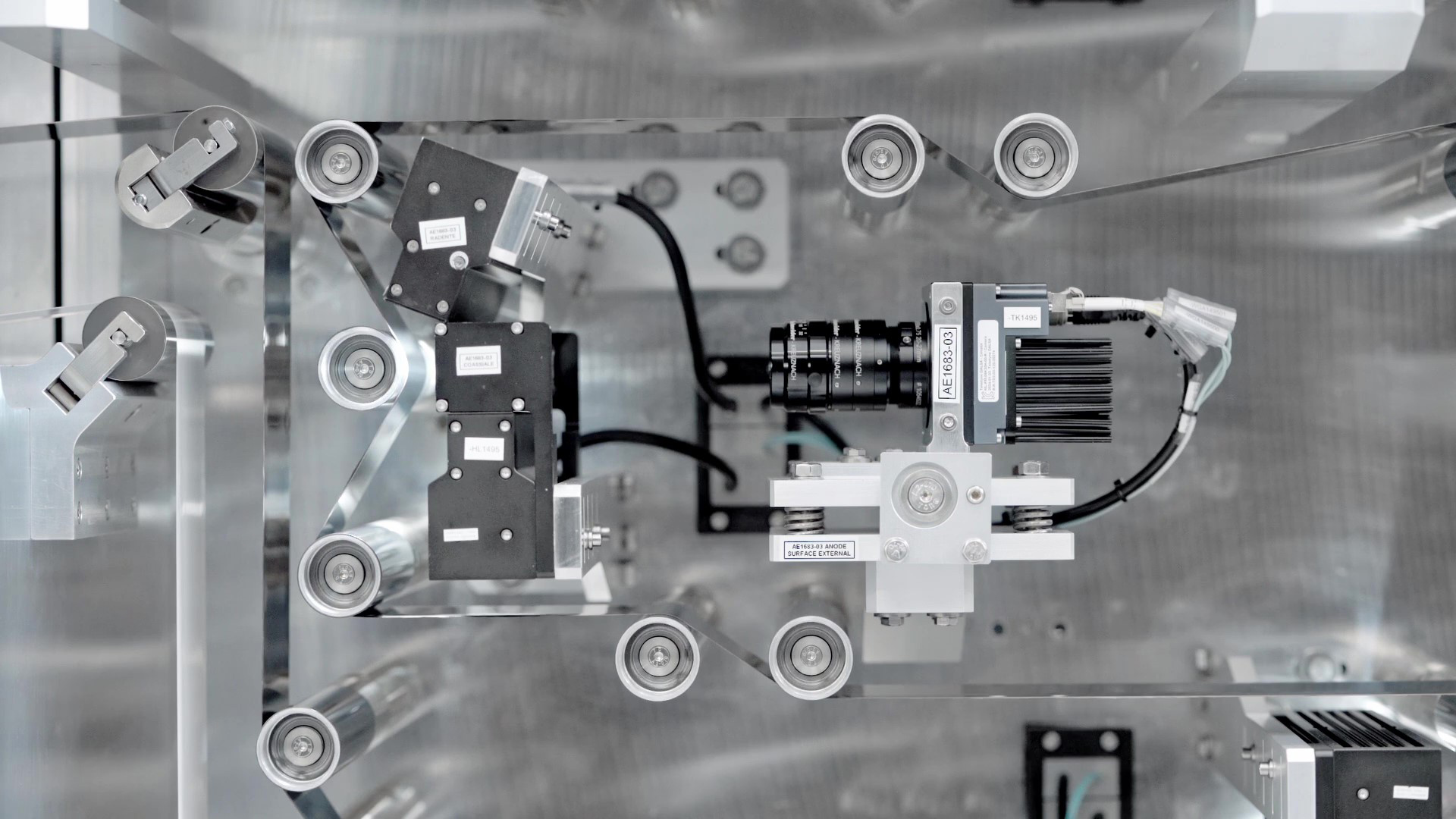

High-Precision Laser Notching and Quality Control

High-power laser notching unit, equipped with dual lasers for unparalleled accuracy in electrodes cuts. The particle extraction system keeps the area clean and free of contaminants, ensuring a safe and spotless work environment. To uphold stringent quality standards, our integrated CCD vision inspection system continuously analyzes coating depth and notch/flags execution, offering an advanced quality assurance solution with unmatched accuracy.

Cleaning and Tab/flags Management

For superior cleanliness, the system features a dedicated cleaning unit that removes any residue from the electrode tabs, both top and bottom, at critical stages like electrodes web notching and cutting. This thorough cleaning enhances the durability, quality, and consistency of each electrode, delivering an end product with improved quality and reliability.

Accurate Winding and Controlled Tensioning with minimum materials waste

Following the cuts of electrodes and separators preparation, motorized winding stations overlap the materials with unrivaled precision and tension control. When a splicing occure on one of the four reels, only one short section of that web is rejected, while the remaining three materials are not rejected at all, without machine stop

Maximum Safety with AGV Integration

The Cylindrical Jelly Rolls Winding system is designed to seamlessly integrate with AGVs, supporting a fully automated, safe, and highly efficient production environment. By minimizing human intervention, this system not only improves safety but also enhances productivity, offering a flexible, high-performance technology for forward-thinking manufacturing operations.