Cell Filling Technology

This advanced production line designed by IMA EV-TECH streamlines the crucial filling, degassing, and final sealing stages of battery manufacturing. Engineered for precision, efficiency, and automation, this line ensures the delivery of superior quality battery cells.

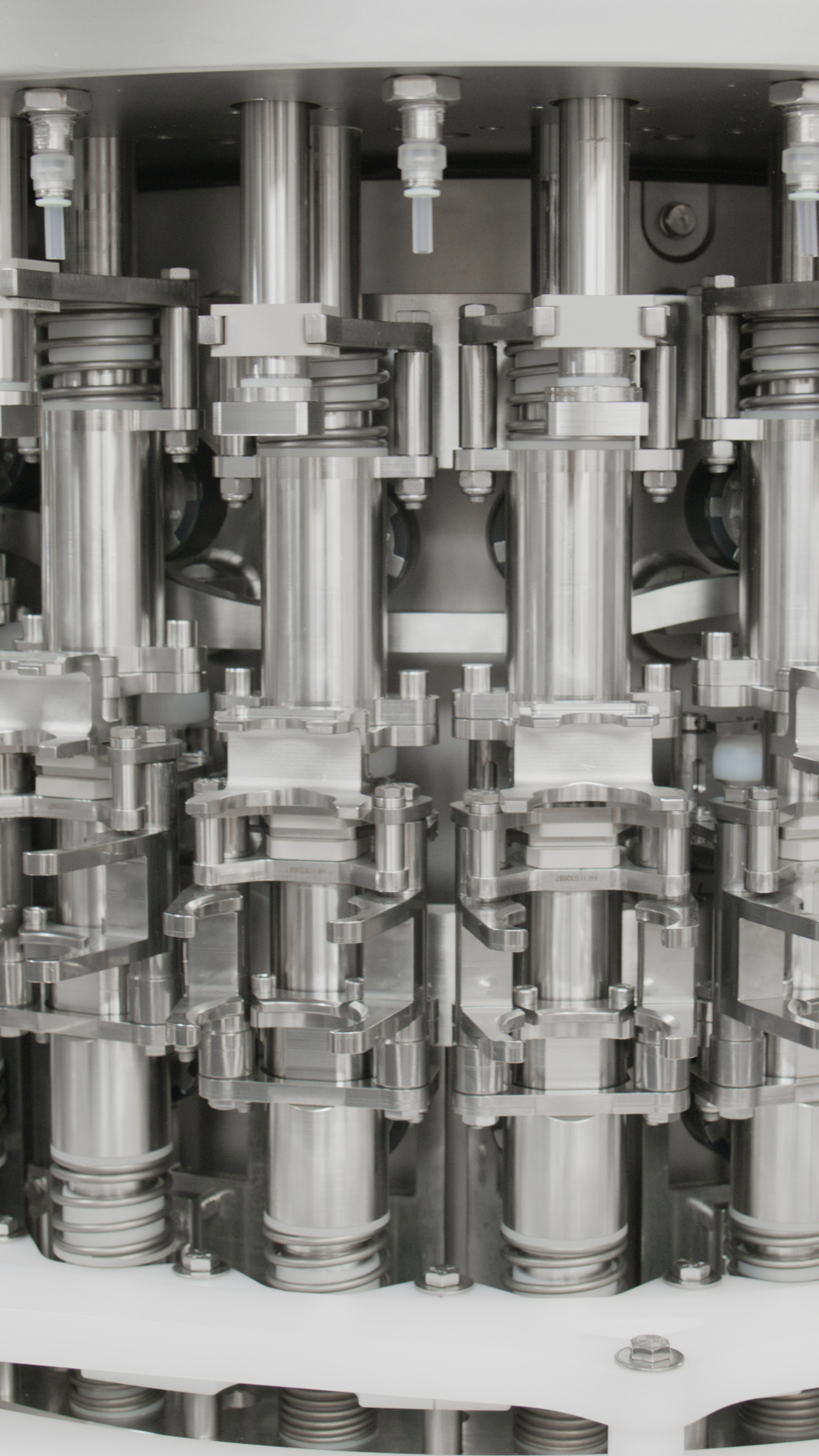

Precision Filling Module

This innovative Filling Module ensures accurate and consistent electrolyte filling, a critical factor for battery performance and durability. It features brushless piston dosing pumps controlled by a PLC system, enabling precise adjustments of dosing volume and filling time to achieve a remarkable accuracy of ±1%. This precision is validated through weight difference measurements. A buffer tank pressurized with nitrogen supplies the filling pumps, while real-time monitoring of product levels and pressure safeguards performance. Safety is enhanced with a pressure valve to prevent overpressure, making this module a cornerstone of consistent battery cell production.

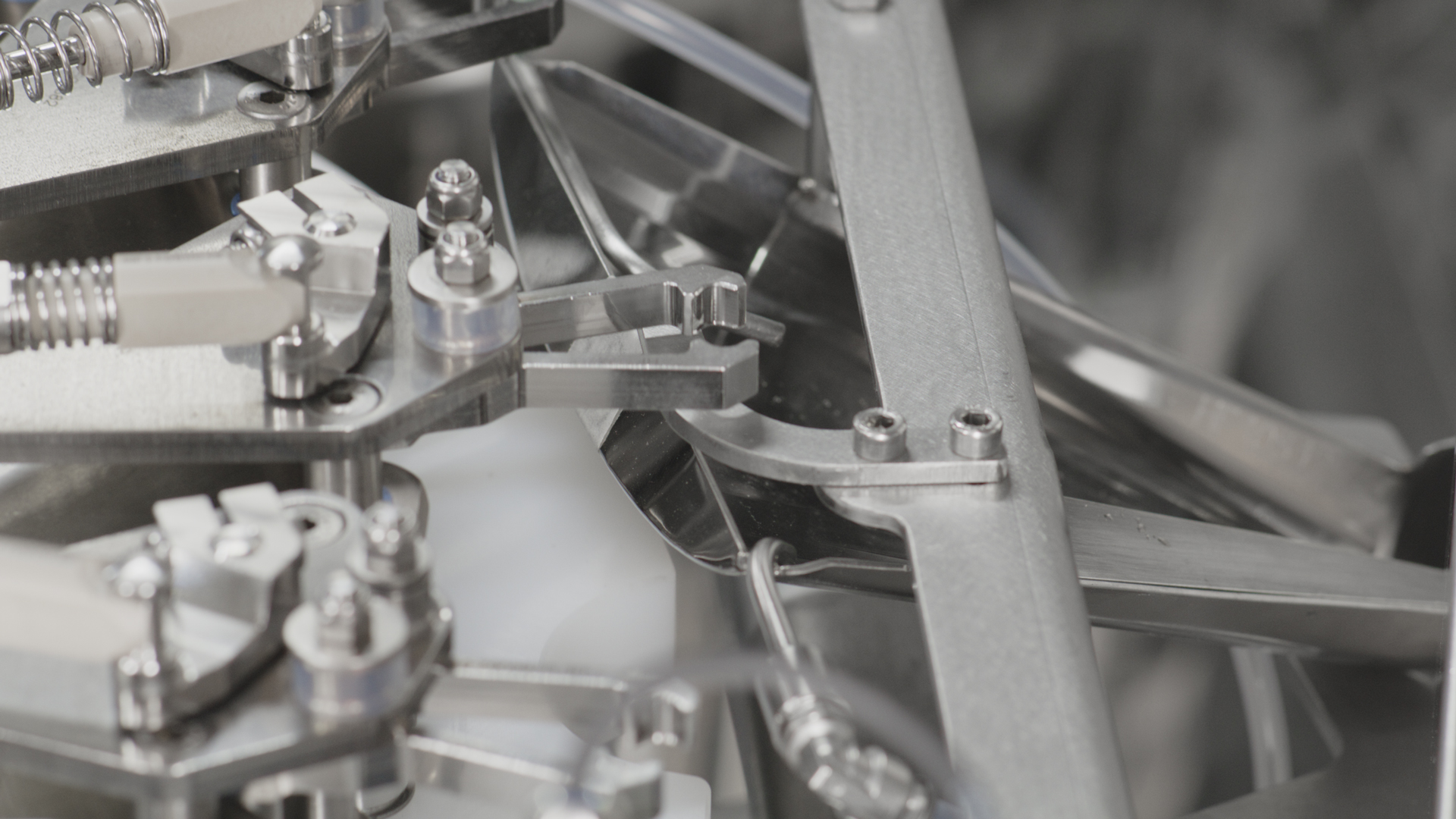

Advanced Degassing & Sealing Module

The IMA EV-TECH Degassing & Sealing Module is designed to eliminate trapped gas from the electrolyte, a crucial step in enhancing battery efficiency and safety. Its dedicated degassing station achieves optimal results within a cycle time of up to 60 seconds. Additionally, DMC rinsing and drying stations ensure the filling hole is clean and prepared for sealing. For final integrity, the module employs laser etching and laser welding stations, delivering permanent and high-quality seals that guarantee cell reliability.

Contamination Control and Traceability

Maintaining a clean environment is critical, and the Contamination Control and Traceability features achieve this by protecting cells from contamination during handling. Working trays and pocket chains are designed to prevent cross-contamination, while the system tracks and traces each cell and operation. This IMA EV-TECH's meticulous approach not only ensures product quality but also supports process optimization and robust quality assurance measures.

Streamlined Operation and Flexibility

With a nominal production speed of 20–24 cells per minute, IMA EV-TECH offers exceptional efficiency lines. Its compact design and manipulators, compatible with various tray configurations, ensure adaptability to diverse production requirements. Automatic format changeover and single adjustment points further streamline operations, reducing downtime and enabling seamless production of different cell formats.

Superior Cleaning Features

To uphold product integrity, IMA EV-TECH developed Cleaning Features that include fully cleanable components designed for use with DMC solvents during flushing cycles. Automatic sanitation cycles eliminate the need for manual cleaning, reducing operator intervention and enhancing efficiency. Components in contact with the product are constructed from AISI 316L stainless steel, renowned for its corrosion resistance and compatibility with battery materials, further ensuring product quality.

A Safer Working Environment

The system incorporates features that prioritize operator safety. Manipulators operate outside the ATEX zone, minimizing exposure to potentially hazardous materials and reducing risks in explosive environments. Automated cleaning and handling systems enhance operator safety, reflecting the system's commitment to providing a secure and efficient workplace.