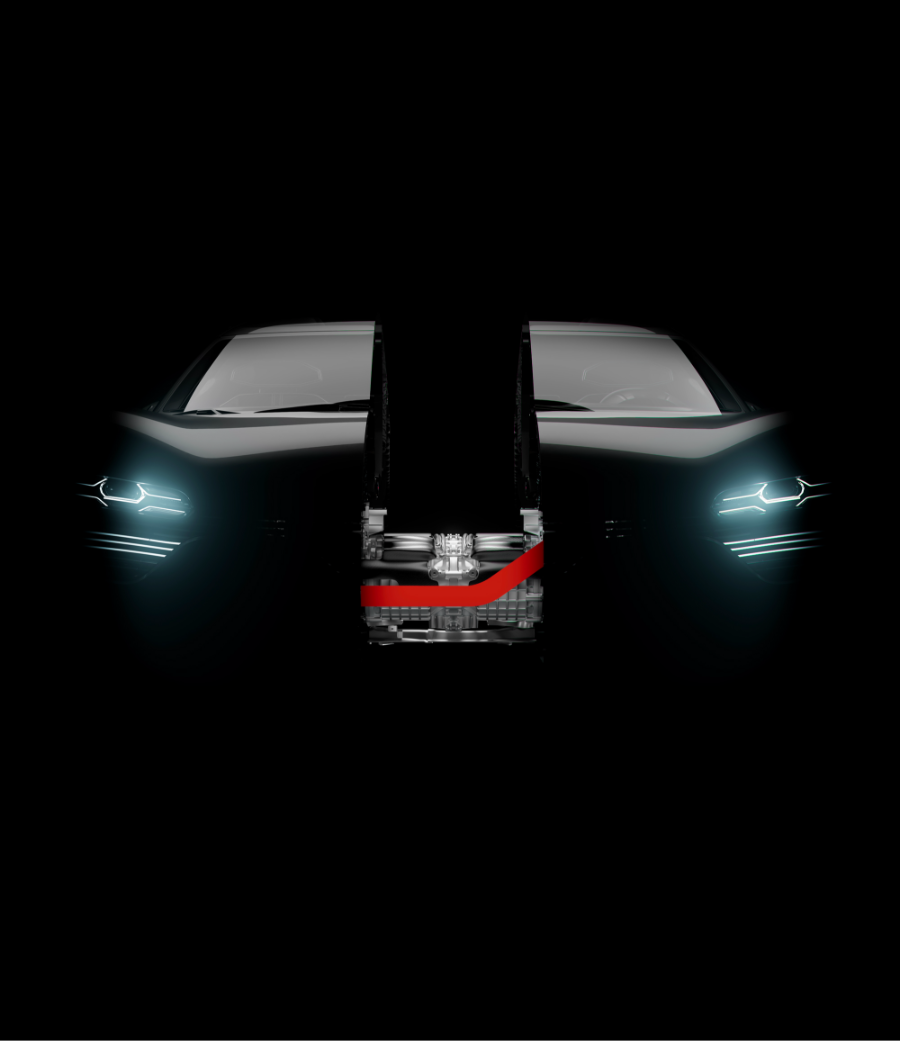

Cell Assembly Solutions

The Cell Assembly machine plays a critical role in the automated assembly of cylindrical lithium-ion batteries. It is specifically designed to carry out a series of precise operations, transforming individual components into a finished battery ready for packaging. This machine is part of a larger production line and manages the mechanical assembly process, handling a variety of components, including pins, lid discs, gaskets, jelly rolls, and cans.

Precision Welding Technologies

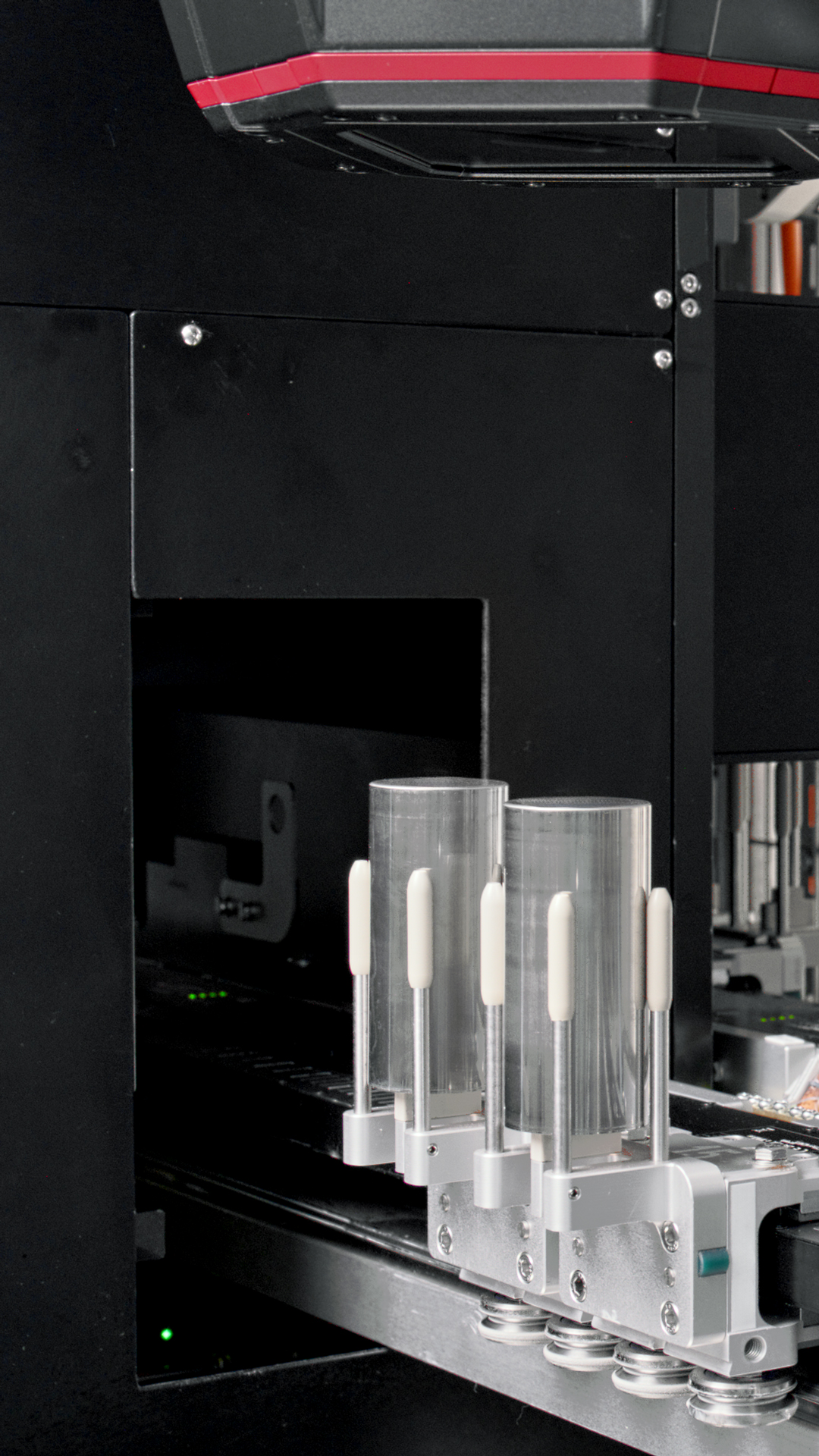

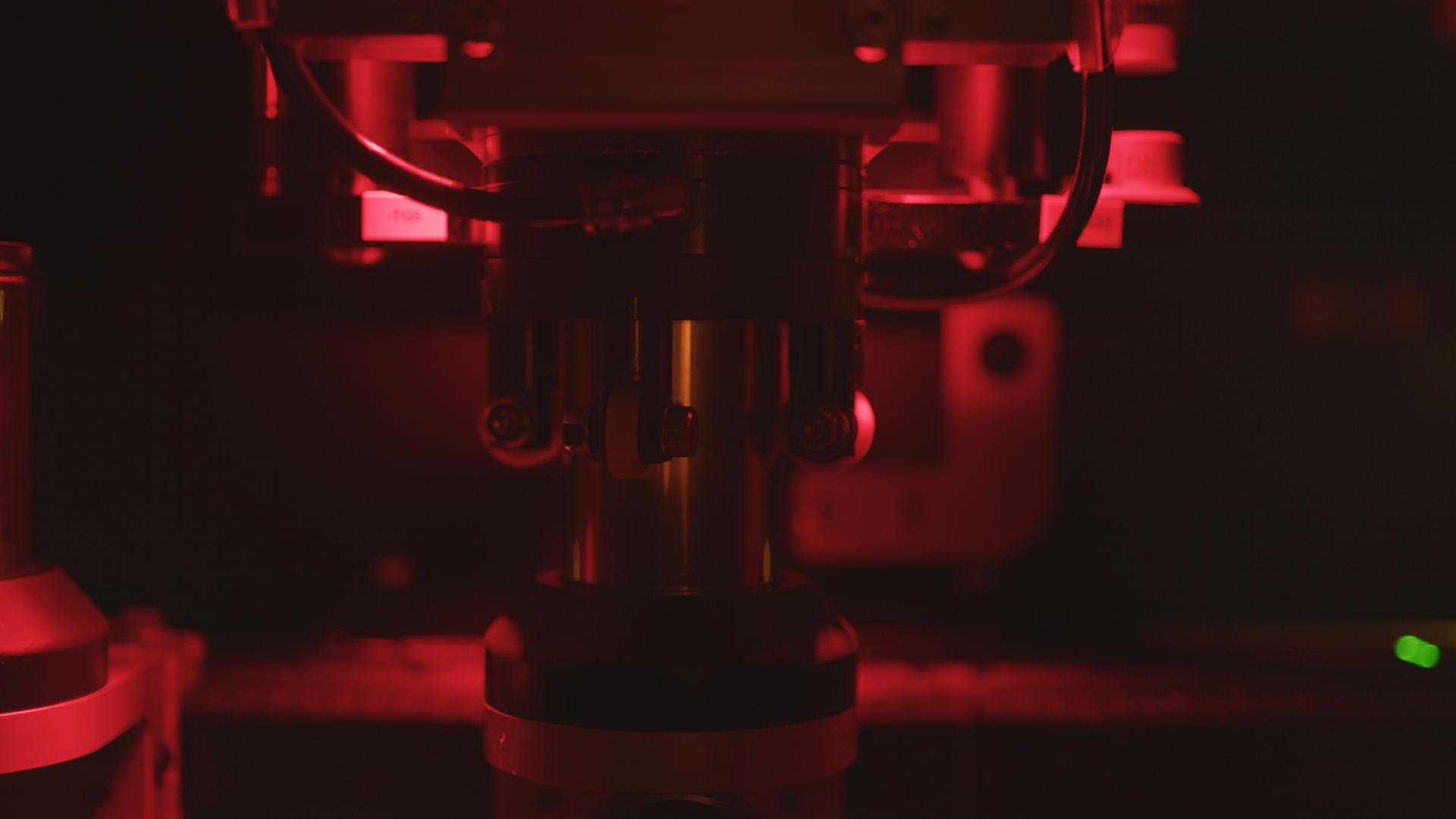

Cathode and Rivet Welding

The CATHODE/RIVET laser welder uses laser technology to create a strong connection between the cathode and RIVET, which is essential for the battery's electrical performance. A visual inspection checks the weld for defects, followed by a resistance test to ensure reliability.

Can and Anode Welding

The ANODE/CAN laser welder then fuses the anode to the CAN, ensuring precise positioning and a durable electrical connection.

Structural Assembly Processes

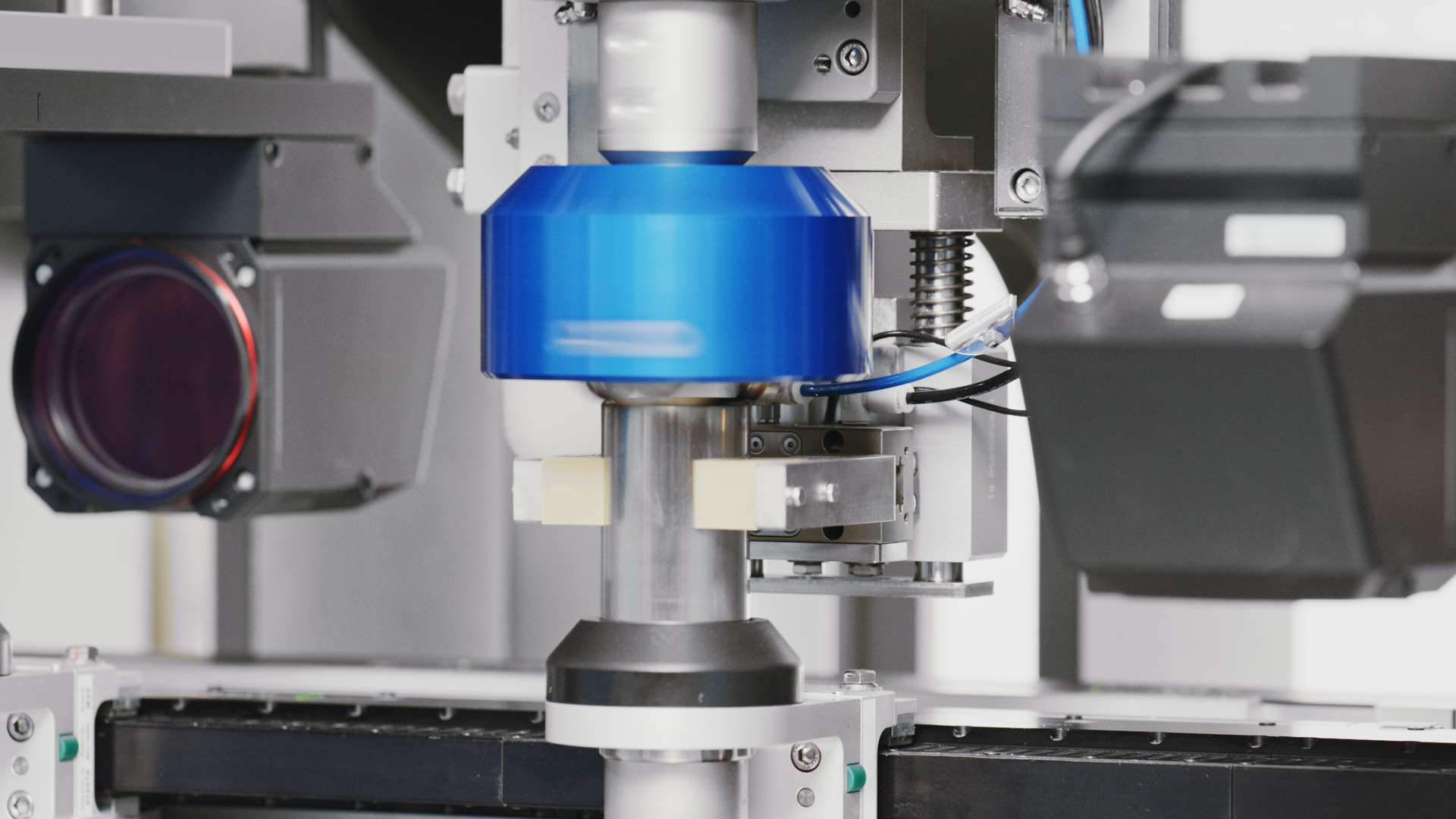

Grooving and initial processing

The CAN is shaped at the GROOVING station to prepare it for subsequent sealing and assembly. Optical measurements verify the accuracy of this initial processing step.

Cleaning and Weld Inspection

A cleaning station removes contaminants from the CAN surface using compressed air and ionisation. This is followed by a visual inspection to confirm the weld's integrity, maintaining high-quality standards.

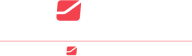

Gasket and Lid Assembly

The GASKET and LID DISC feeders supply components to the LID/GASKET assembly system, which combines and loads them into the machine. This process creates a sealed environment that protects the battery's internal components and ensures safe operation.

Crimping and Shaaping

The CAN undergoes a two-step crimping process to form an airtight seal. The first and second CRIMPING stations shape the CAN, with telecentric optical measurements after each step to ensure precision. The SIZING station completes the process by pressing the CAN to its final shape.

Final Testing and Quality Control

Grooving and initial processing

The CAN is shaped at the GROOVING station to prepare it for subsequent sealing and assembly. Optical measurements verify the accuracy of this initial processing step.

Cleaning and Weld Inspection

A cleaning station removes contaminants from the CAN surface using compressed air and ionisation. This is followed by a visual inspection to confirm the weld's integrity, maintaining high-quality standards.

Quality Control

A quality control station ensures only high-quality batteries proceed to packaging. Conforming products are directed to the downstream 7R6 machine, while nonconforming ones are rejected.

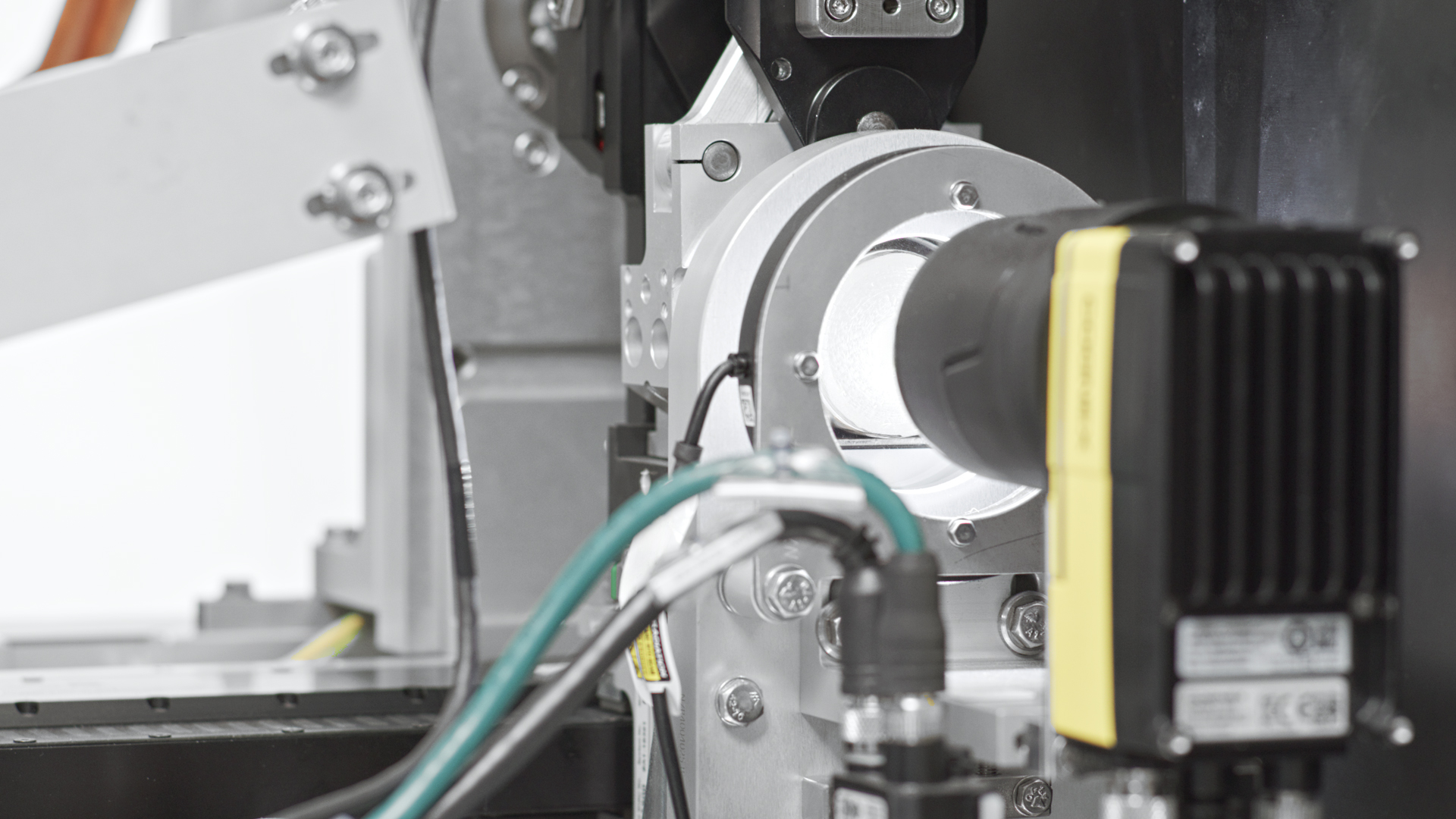

X-Ray Inspection

For enhanced quality assurance, the X-ray unit examines the battery's internal structure. Products passing this inspection proceed to packaging, while defective ones are rejected.