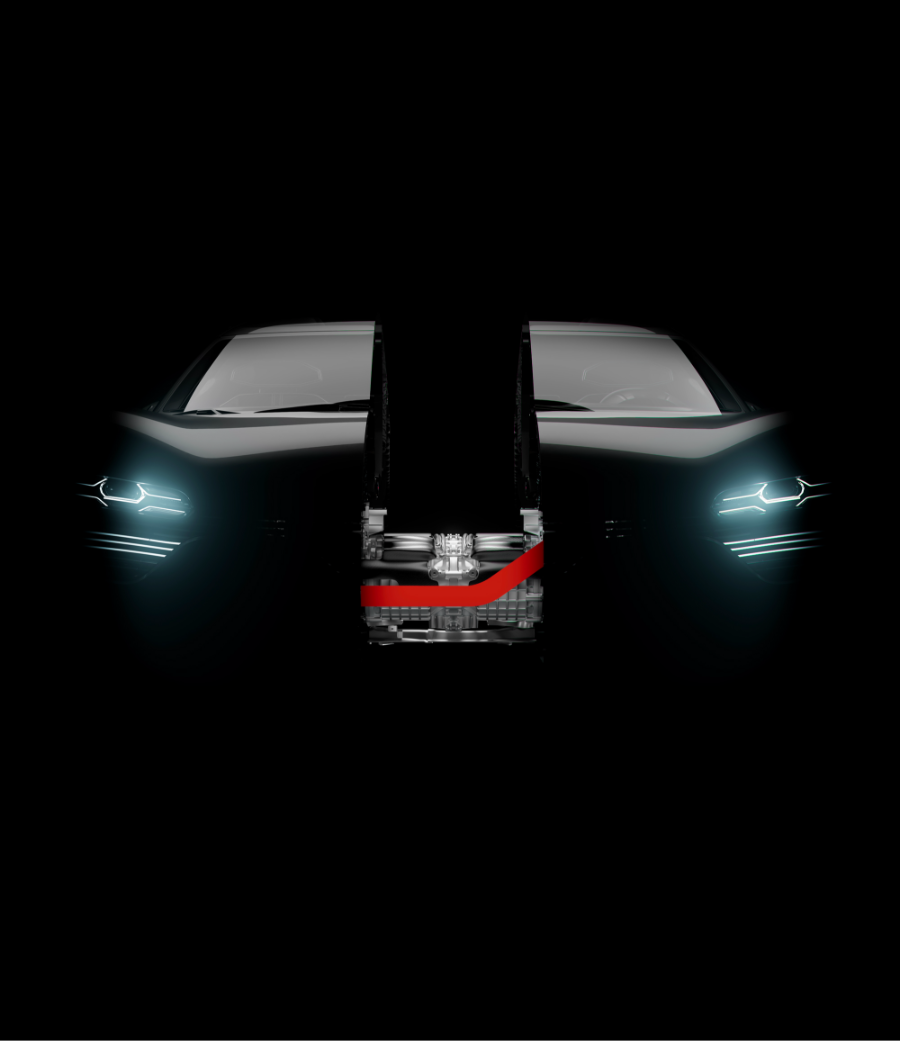

Can Riveting Technology

The Can riveting technology is an advanced solution for assembling cylindrical components of lithium-ion batteries. This technology mechanically assembles

the rivet and gasket components inside the Can, providing a secure and durable connection critical for the structural integrity of the final product.

Following the riveting process, the technology enables the precise insertion of the insulator into the Can. Capable of operating at a speed of 30 products per minute,

Can riveting technology is seamlessly integrated into automated production lines, making it an ideal choice for high-productivity battery cell manufacturing.

Can Handling and Assembly Process

The Can Inlet Belt enables seamless transfer of Cans between machines using a magnetic toothed belt driven by a motor, with sensors ensuring precise positioning. The Main Conveyor ensures efficient Can transport through assembly and inspection stations via linear motors and guided trolleys, reducing handling time and ensuring consistent processing.

Cleaning Solutions

The Cleaning Stations enhance product quality and process reliability by removing contaminants from Cans before and after critical processing stages. Using de-ionised air knives, these stations effectively clean the Cans while integrated extraction systems and filters maintain a clean environment, preventing cross-contamination and ensuring consistent production standards.

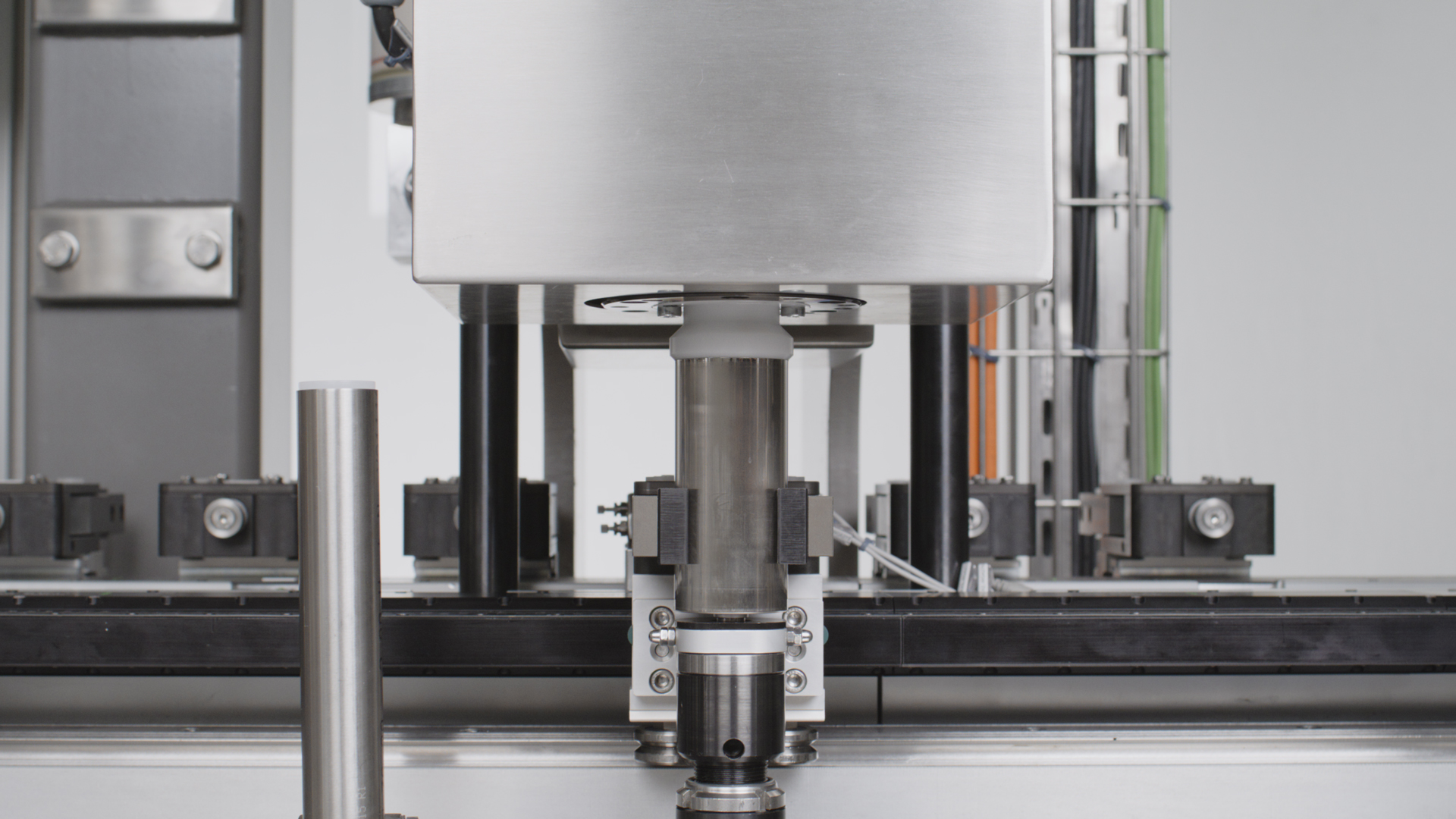

Component Feeding and Assembly

The rivet and gasket feeders provide a continuous supply of components using vibrating hoppers and outfeed channels, with sensors monitoring orientation and levels. Pick&Place units, equipped with linear Cartesian motion and gripping mechanisms like pneumatic grippers and vacuum generators, ensure accurate and safe handling of rivets, gaskets and insulators. At the assembly and riveting stations, gaskets and rivets are combined using a translation plate and pneumatic actuator, then secured inside the Can with a riveting head and lower punch.

Inspection Activities

Comprehensive checks at Inspection Stations ensure product quality. These include:

- Contact transducers to verify component presence.

- Optical fibers and profile meters for dimensional accuracy.

- Vision systems for assembly verification.

Quality Control

The Laser Marking Station adds traceability by applying a unique laser-marked code to each Can, verified by a code reader. Airtightness Check Stations test Can seals using probes, suction cups, and airtight closure heads, while Insulation Check Stations measure electrical resistance between the Can and Rivet to ensure safety and functionality.

Final Handling

The Product Outfeed automates the separation of conforming and nonconforming products. A Pick& Place unit directs finished products to the exit belt or rejection belt based on inspection results, streamlining final processing and facilitating rework where necessary.