03/18/2022

IMA AUTOMATION at Coiltech Deutschland 2022

The Automotive and Electrical Motors sectors of the IMA AUTOMATION Hub is exhibiting at Coiltech Deutschland 2022: IMA AUTOMATION ATOP and IMA AUTOMATION FASP are gathering up in Ulm on April 6th and 7th for the first edition of Coiltech in Germany.

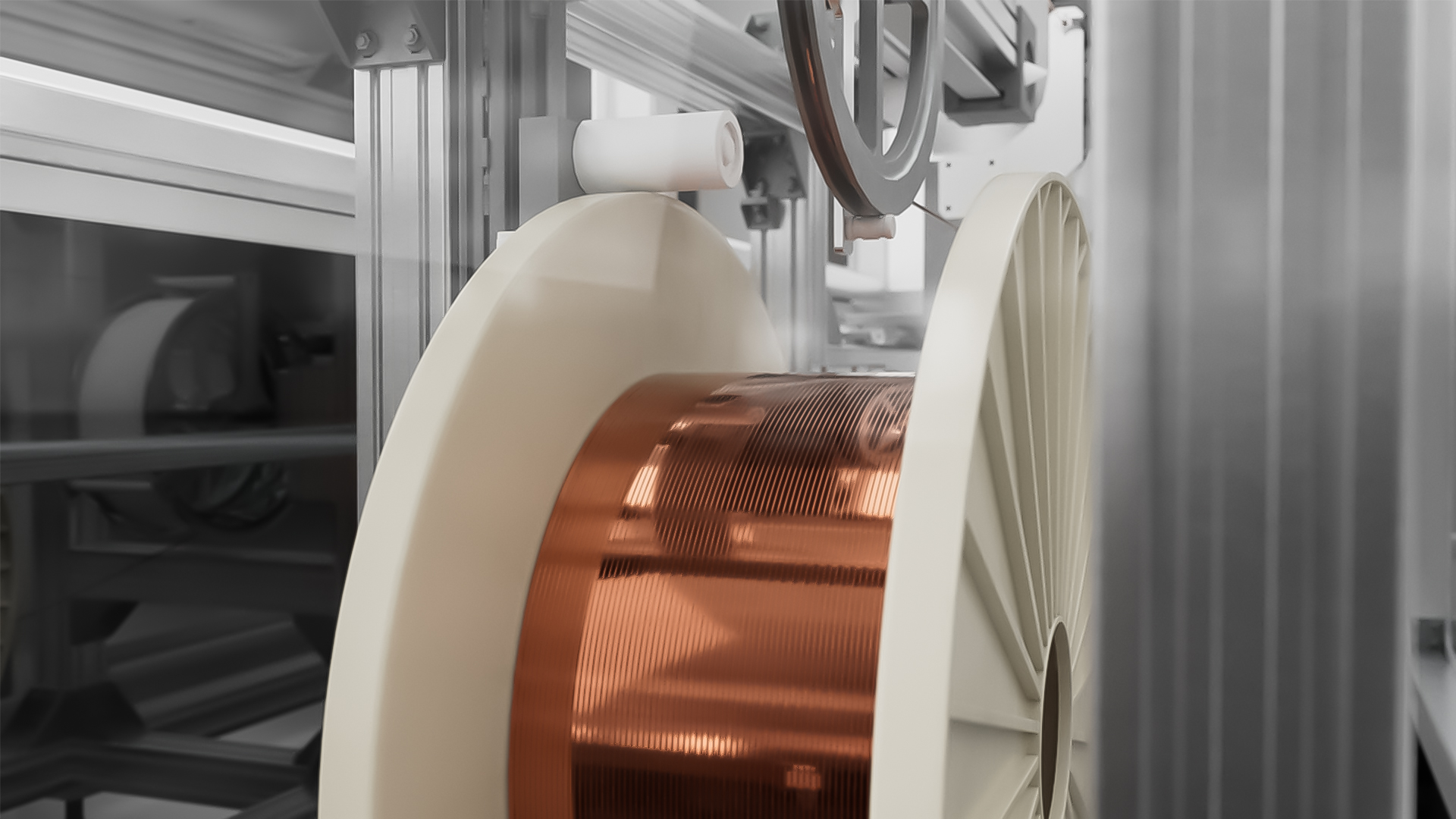

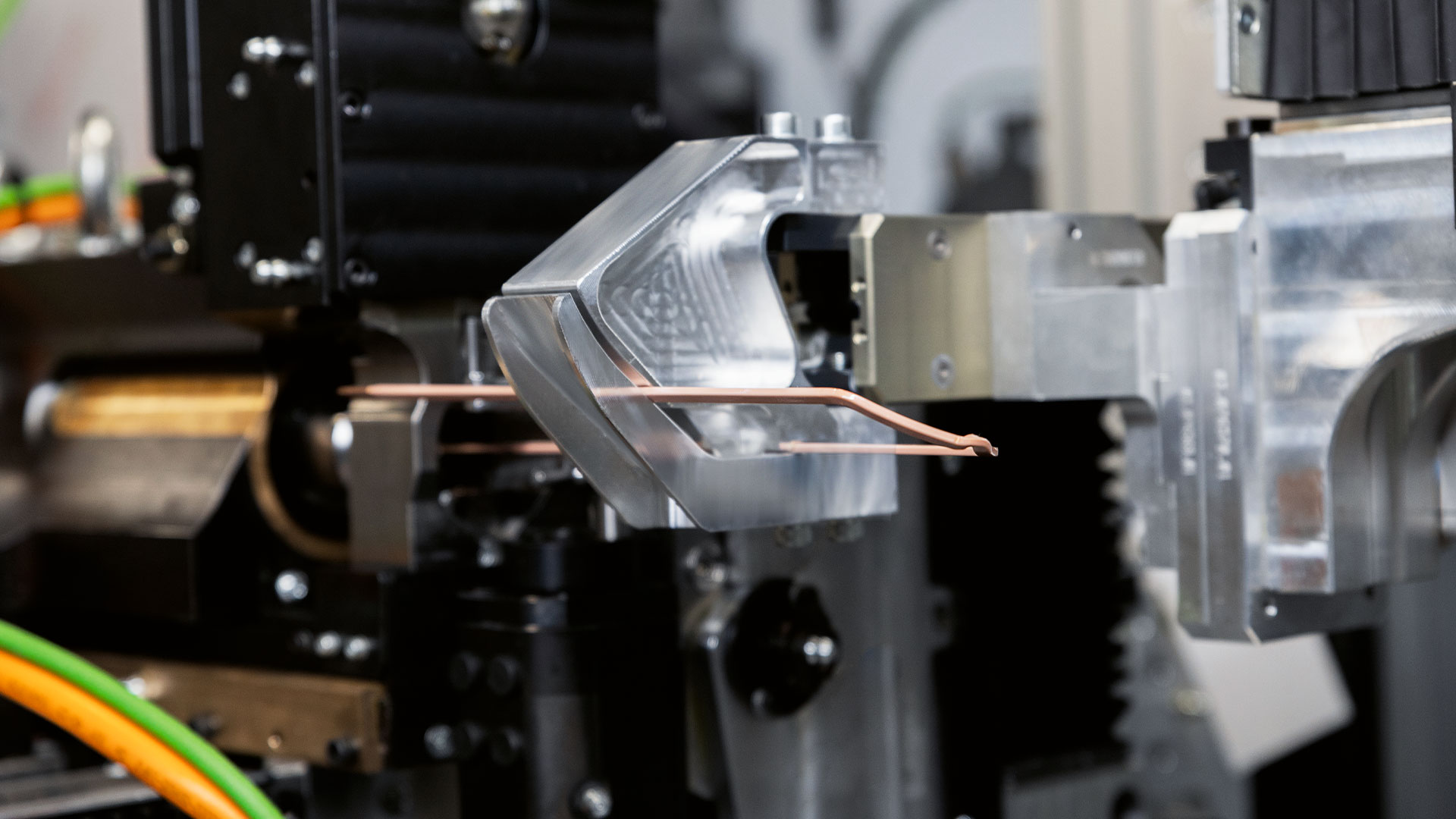

The focus of the event will be the assembly of advanced electrical motors with specific winding solutions: hairpin, needle, flyer and inserting technologies.

Electrical motors for automotive, industrial applications, power tools and household appliances are one of the point of strength of the Group’s Automation hub, with a wide range of tailored solutions to suits all the business’s needs.

Join us in Ulm and discover the Automotive and Electrical Motors sections of the IMA AUTOMATION hub: technologies and machinery for the production and maintenance of electric motors, generators, power and distribution transformers, industrial transformers and windings.

Come meet our experts on our stand: IMA AUTOMATION Hall 1 - A20

Get the chance to discover more about these market sectors on show:

Industrial Applications

Electrical motors for industrial applications are designed to guarantee high reliability and resistance.

IMA AUTOMATION ATOP and IMA AUTOMATION FASP present the widest range of tailored solutions to meet customers' requirements. From stand-alone machines to produce prototypes to complete automatic lines for brushless motor series production, for the processes of lamination staking, slot insulating, winding, wire-leads termination and electrical testing.

Power Tools

Our know-how and continuous innovation allow us to supply tailored solutions with high technological content to produce the latest generation electric motors for the power tools appliances, which are more and more efficient, compact and with reduced energy consumption.

Household Appliances

Electric motors have found large use in the household appliance industry and in our daily life. They’re present in very small or big appliances for the food preparation, the house cleaning and the body care.

Our machines represent the technological excellence as regards brushless stators winding, being able to wind a high number of turns at high speed and to guarantee maximum performance, efficiency, process repeatability, flexibility and reliability.

Traction E-motors assembly

Cutting-edge and modulated technology for large scale production of stators and rotors for traction electric motors. Focus on continuous e-traction technological development in hairpin and other winding technologies, with the highest flexibility upon customer requirements.