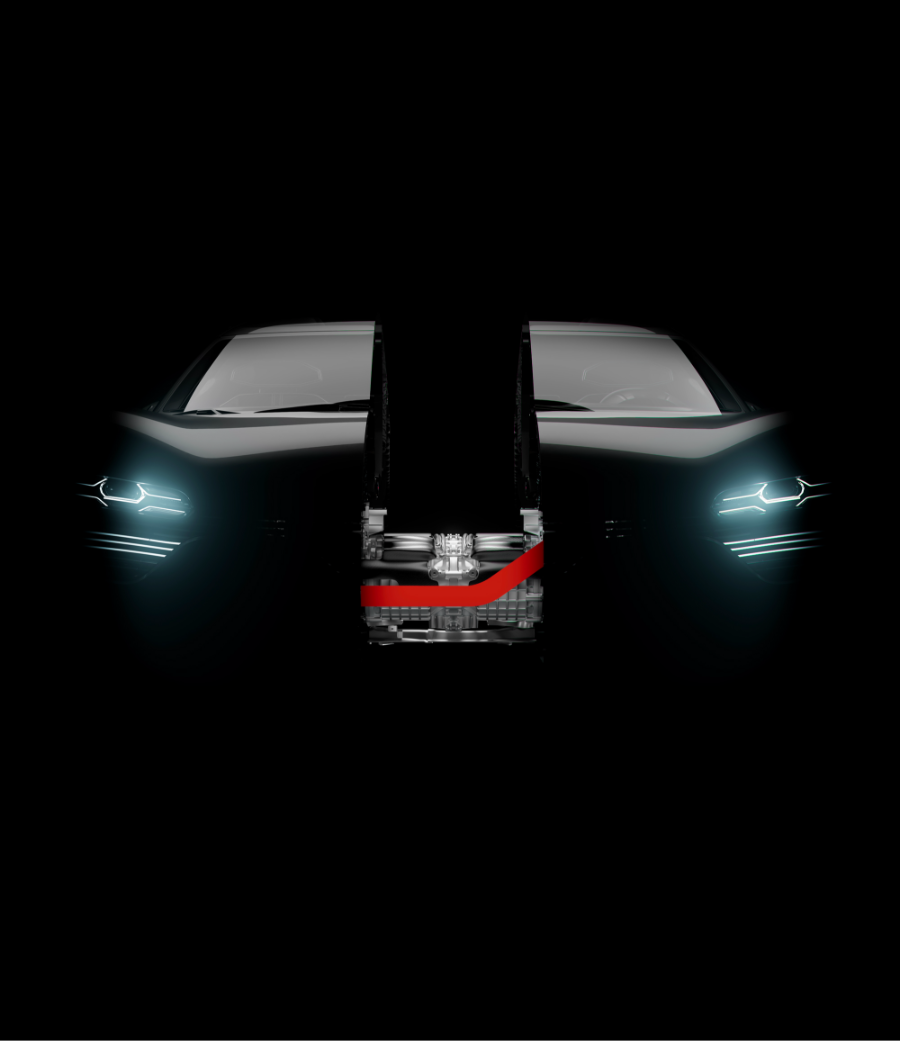

Inserting Coil Winding

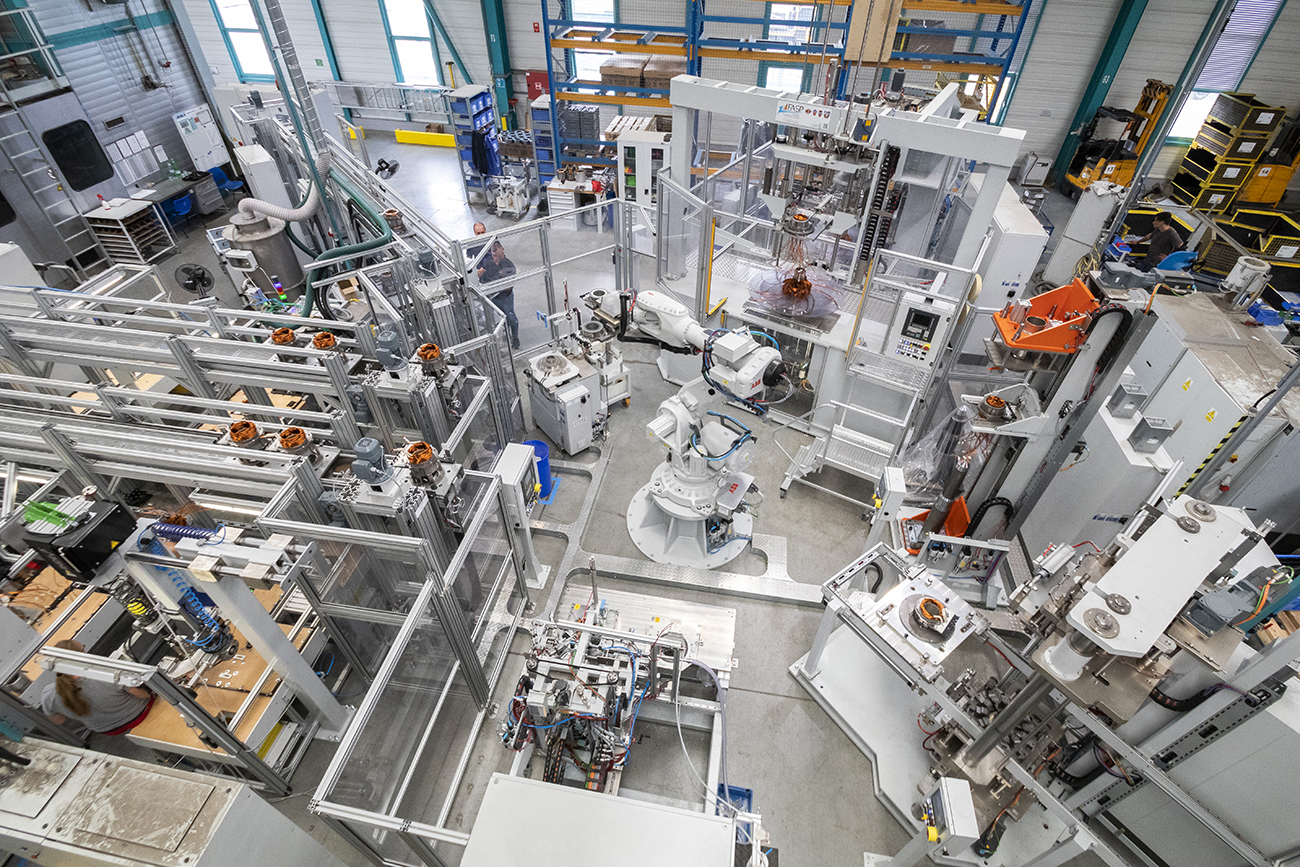

Semi-automatic and full automatic process cells with dynamic management and production lines for the wound stator.

IMA AUTOMATION has a high experience on the manufacturing of complete process cells by stand alone machines, up to fully automatic coil winding lines for the stators process. The main markets area are Electric motors for industrial sector, Traction EV motors for different applications, generators for power energy and Submersible motors and standard pumps motors. With a strong orientation to the automation and the flexibility.

The machines developed by IMA AUTOMATION are self-adjusted during the various manufacturing phases, thanks to the integration on the stator assembly process of DPS1 (Dynamic Process System 1). It allows to manage automatedly all the steps of the motor production and also allows the machines to self-change automatically the setting-up in a controlled way accordingly with the winding specifications, such as the coil dimensions and the turns number, parallel wires, forming shape of winding heads, lacing process etc..

The key technology called DPS1 System technology involves:

- the production of stators with different specifications in a dynamic mode

- a high flexibility process, managing different stator types on efficiency mode

- high production standards and accuracy in processing

- the possibility of constant flows monitoring

- a high OEE production efficiency, over 85%

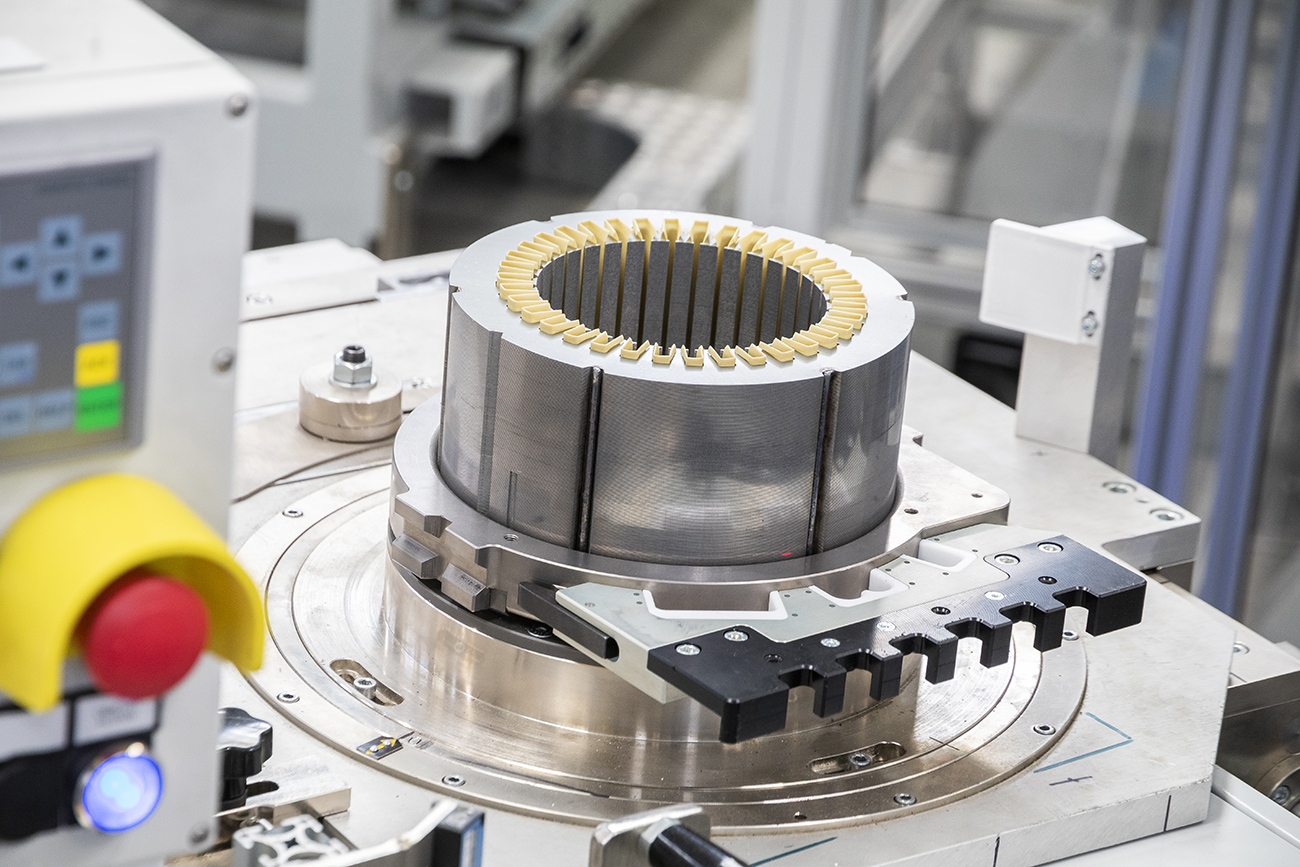

Stator assembly process

Stator and rotor assembly process, also with robotized welding process, achieving the highest flexibility on product variations to be processed, both with straight and inclined assembly, including the subsequent welding with various technologies, such as TIG, CMT and Laser. All is made with highly flexible robot systems that can be integrated into automated processes.

Slot bottom insulating process

IMA AUTOMATION designs and manufactures machines and plants for slot bottom insulation process, wedge making process for different product variations with several technological solutions: by using insulators with modulated height in relation to the height of the stator packs and through the use of insulators according to the slots design. The machines are highly performing, extremely flexible, and can be integrated into robotic cells and on high efficiency automatic lines.

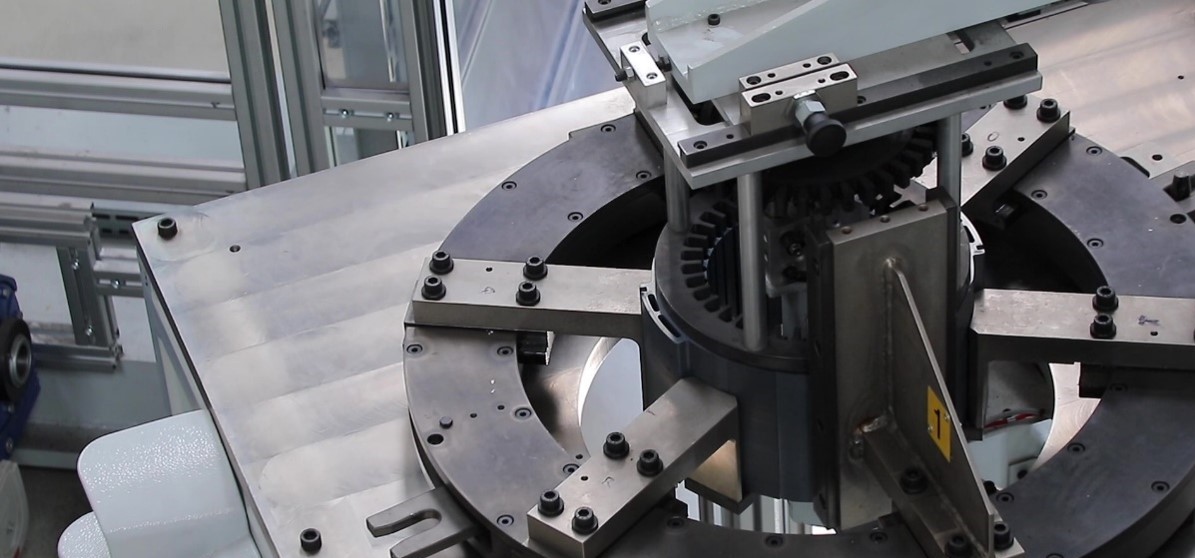

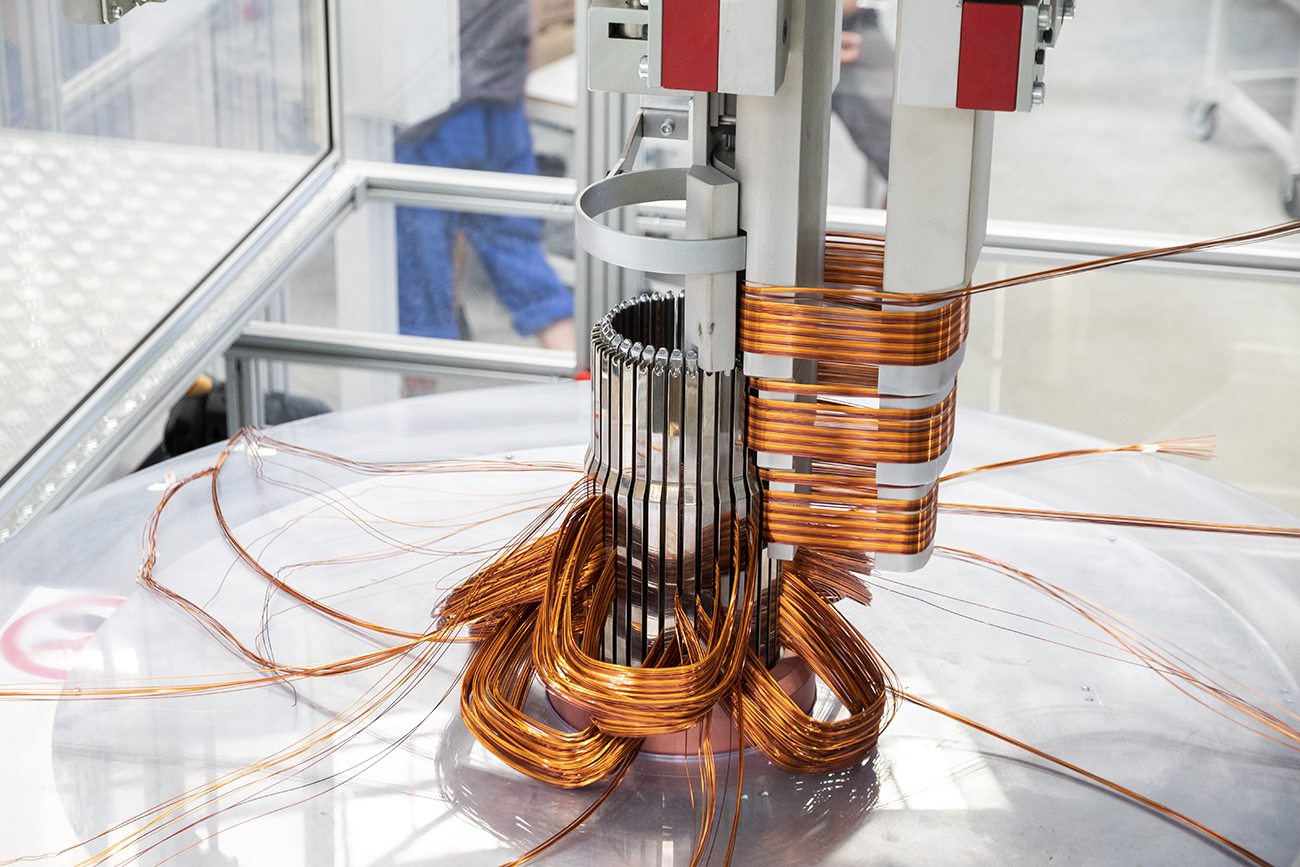

Coil winding process

Process with innovative winding technologies:the flyer technology, applied in high performance processes with winding bow, and the rotating forms technology (called free twist technology), which eliminates the twist effect in case of winding with many in parallel wires, in this case allowing to reach up to 90% of full fill factor on the winding assembly on the stators. IMA AUTOMATION also produces special systems for processing standard stator. Generators, stators and EV vehicle stators with high performance required. The machines’ range covers all sizes up to IEC 315 motor, including special motors. Particular skills examples:

- Fully automatic format change of the height of the stator pack (on free twist coil winding technology)

- Possibility to produce concentric and semi-imbricate coil winding schemas (complex windings technology)

- Leads length programmable, one by one lengths management (flyer technology and free twist technology)

- Automatic selection of the number of wires in parallel (on free twist coil winding technology technology)

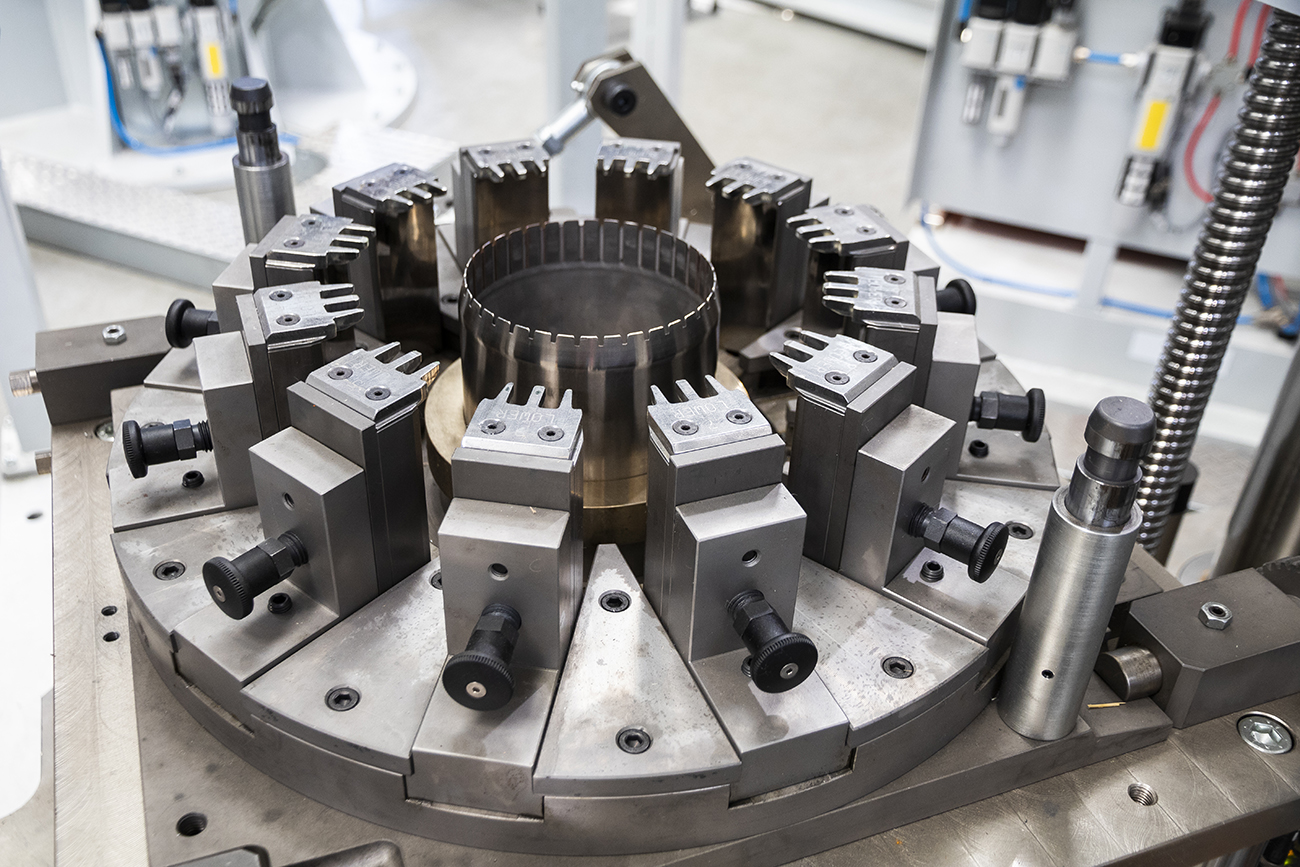

Winding heads forming process

Machines and plants developed for shaping the coil windings during the coil insertion process and along the finishing process, up to reach the final winding heads geometry required from the projects specification (expanding process on between different coil inserting process steps, preforming of winding heads for phases insulation operations, intermediate and final forming process with 3D shaping technology up to the calibration of winding heads shape on process end).

The winding heads expanding and forming machines are configured with different levels of technology and of equipment supplied to meet the quality needs and the winding heads forming quality and performances:

- winding heads expanding technology

- winding heads preforming technology

- winding heads intermediate forming technology

- winding heads final forming technology

- winding heads calibration technology

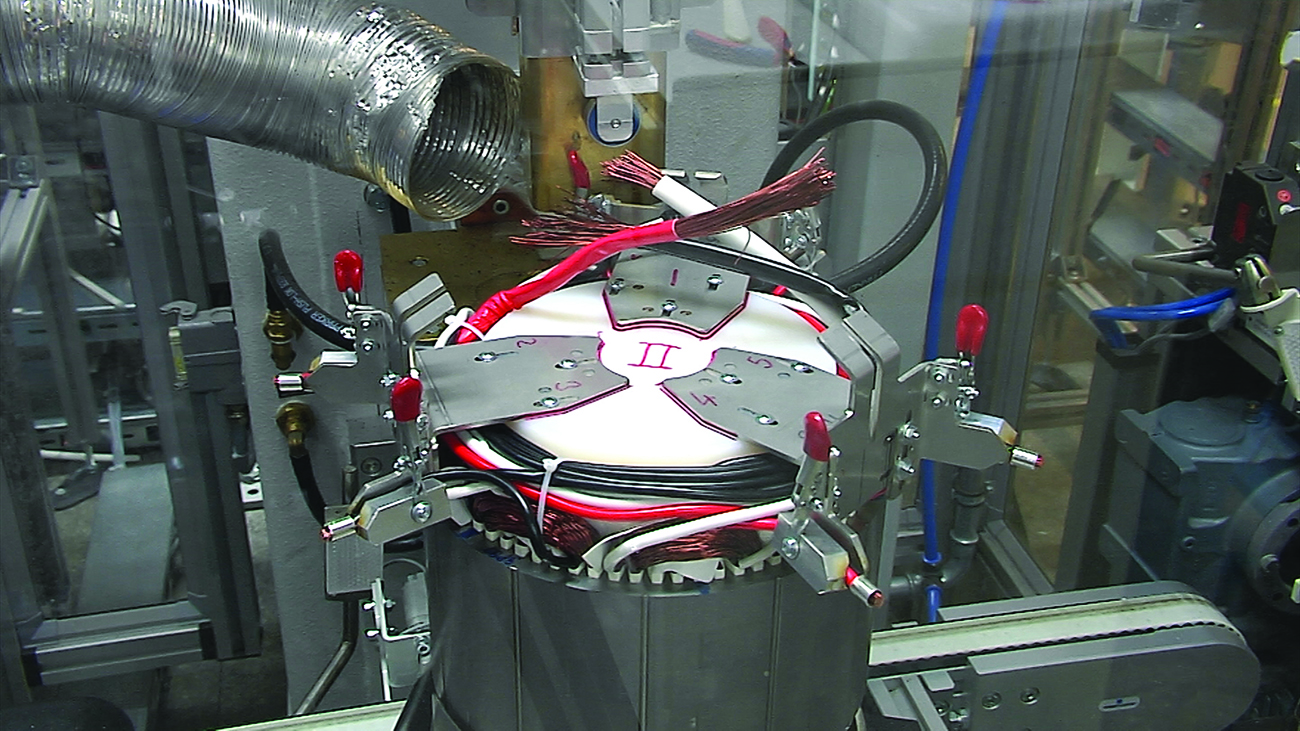

Leads connection process

Automatic systems for leads connection operation, managing four main technologies.

- Cold leads connection technology

- Crimping and fusing connection technology

- Tube crimping and fusing connection technology

- BUS-BAR connecting technology

Furthermore, IMA AUTOMATION is able to supply sleeve distributors on the leads that manage the operations and the insulation of the connections by means of a gluing system on BUS-BAR applications.

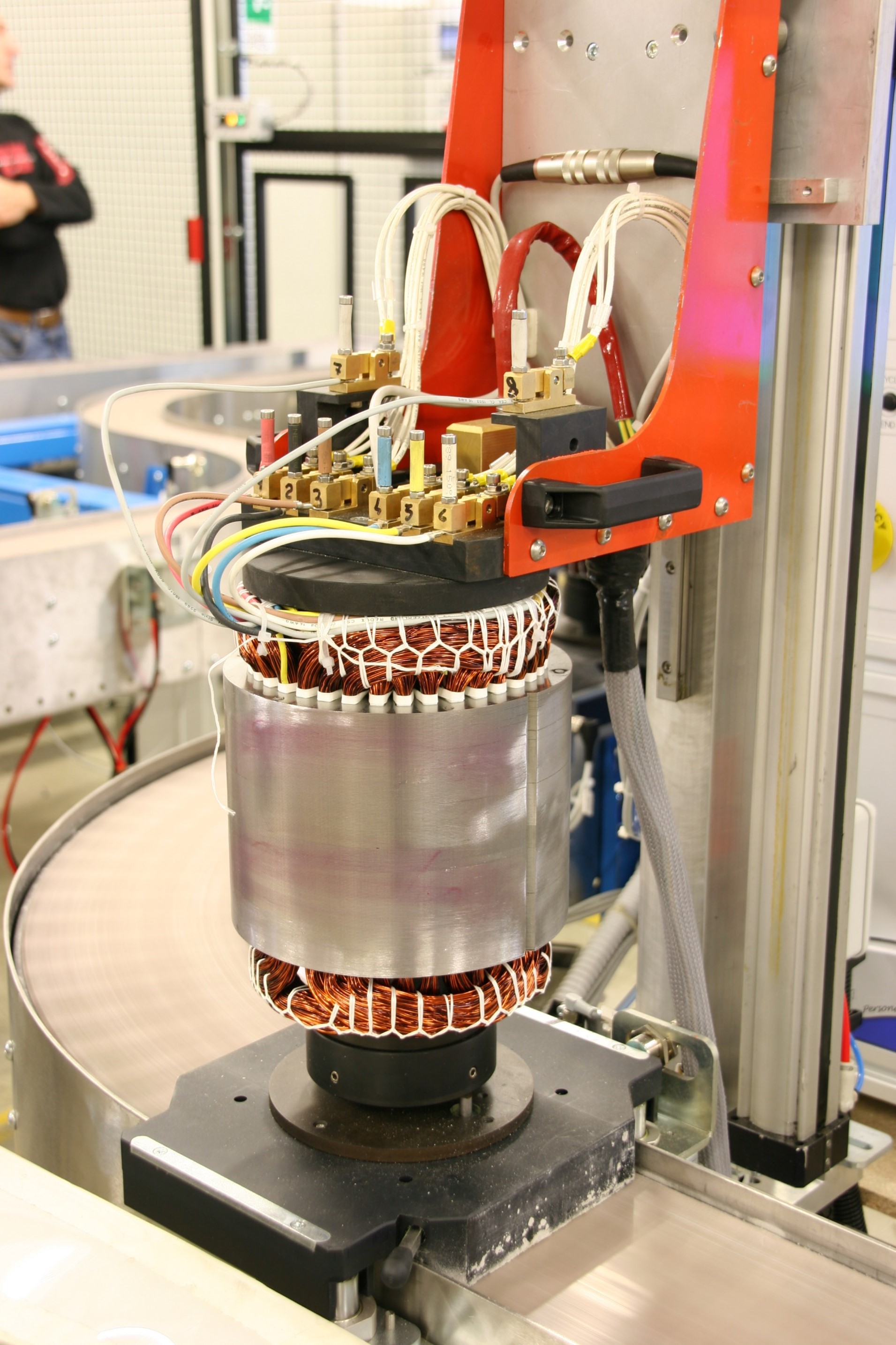

Winding heads lacing process

The machines are provided with single or double lacing unit configuration on Diamond Lacing technology. They are made by high level flexibility thanks to the independent and interpolated CNC machine movement and a dedicate numerical control. All the machines are realized for manual and robotized stator load unload.

Many configurations are available:

- Single lacing with single stator support unit, extremely flexible machine.

- double lacing with single stator support unit, standard machine.

- double lacing with double stator support unit on rotating table, to reach the highest performances.

- double lacing with multiple stator support unit.Maximum flexibility and no setting needed.

End stator assembly process

The electrical test stations are developed with the higher standards and managed totally from IMA AUTOMATION, also for calibration service when required, to cover the 360 degrees the customers needs.

The end process electrical test stations are configured with different levels of technology and of equipment supplied to meet the quality needs and the winding heads forming quality and performances:

- Single stator support station.

- Double stator support station.

- Conveyer system with semi-automatic test station.