In the context of Industry 4.0, the digitalization of production processes is a key element for ensuring flexibility, efficiency, and control. In this scenario, IMA AUTOMATION has implemented advanced simulation and virtual commissioning tools to support the design, validation, and commissioning phases of its automated lines.

Real-Time virtual commissioning, virtual testing, real savings

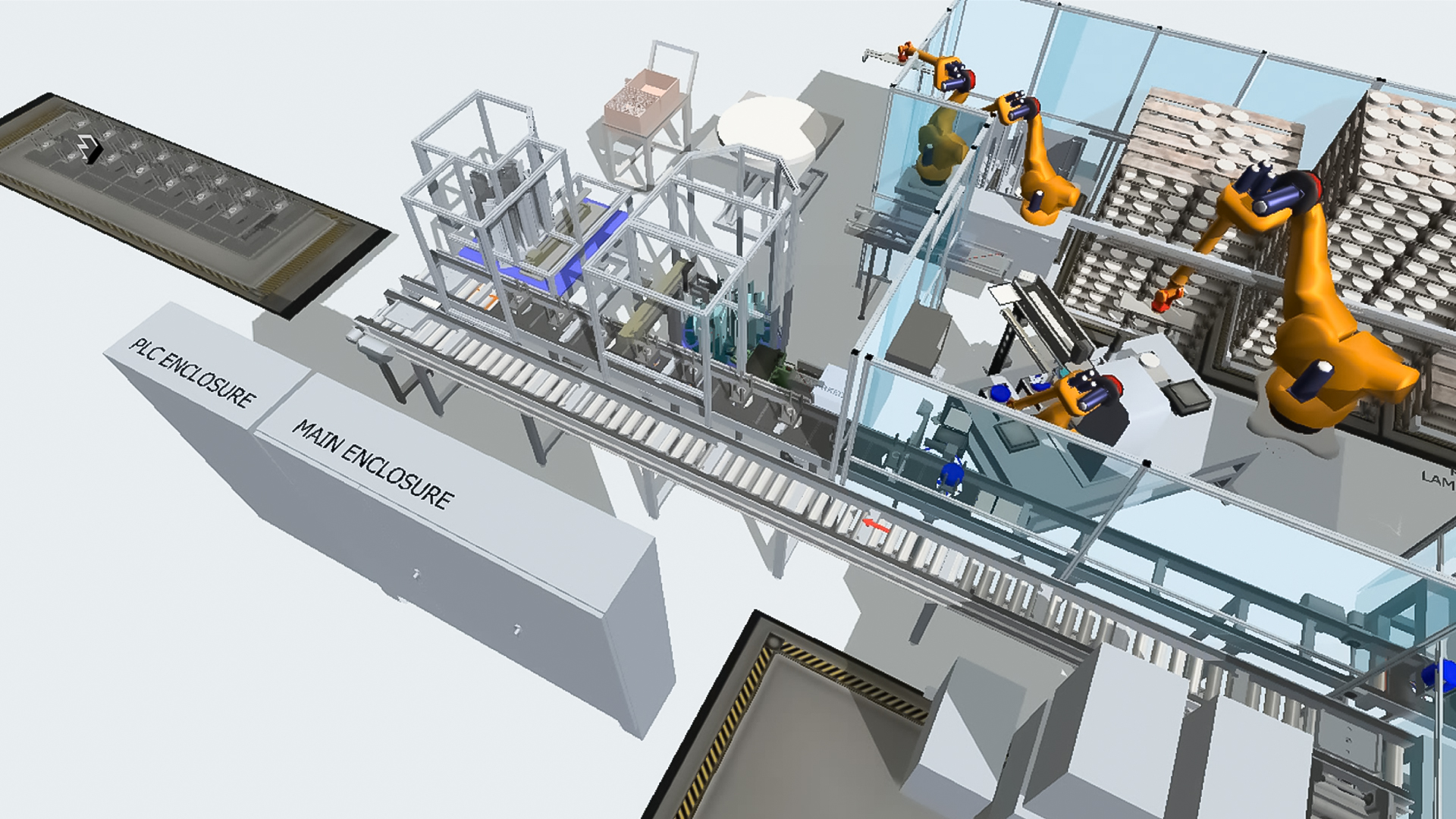

Virtual commissioning enables the virtual startup of a machine or line, significantly reducing the time and costs associated with physical commissioning. Through real-time connection with the PLC, it is possible to test and verify control software and automation logic even before the physical system is built.

Key benefits:

- Reduced time-to-market;

- Increased safety through early detection of logic errors;

- Early training opportunities for operators.

Advanced functionalities:

- Direct interface with robotic modules, including simulation of kinematics and trajectories;

- Validation of synchronous behavior between robots, conveyors, and workstations;

- Real-time event simulation with PLC synchronization.

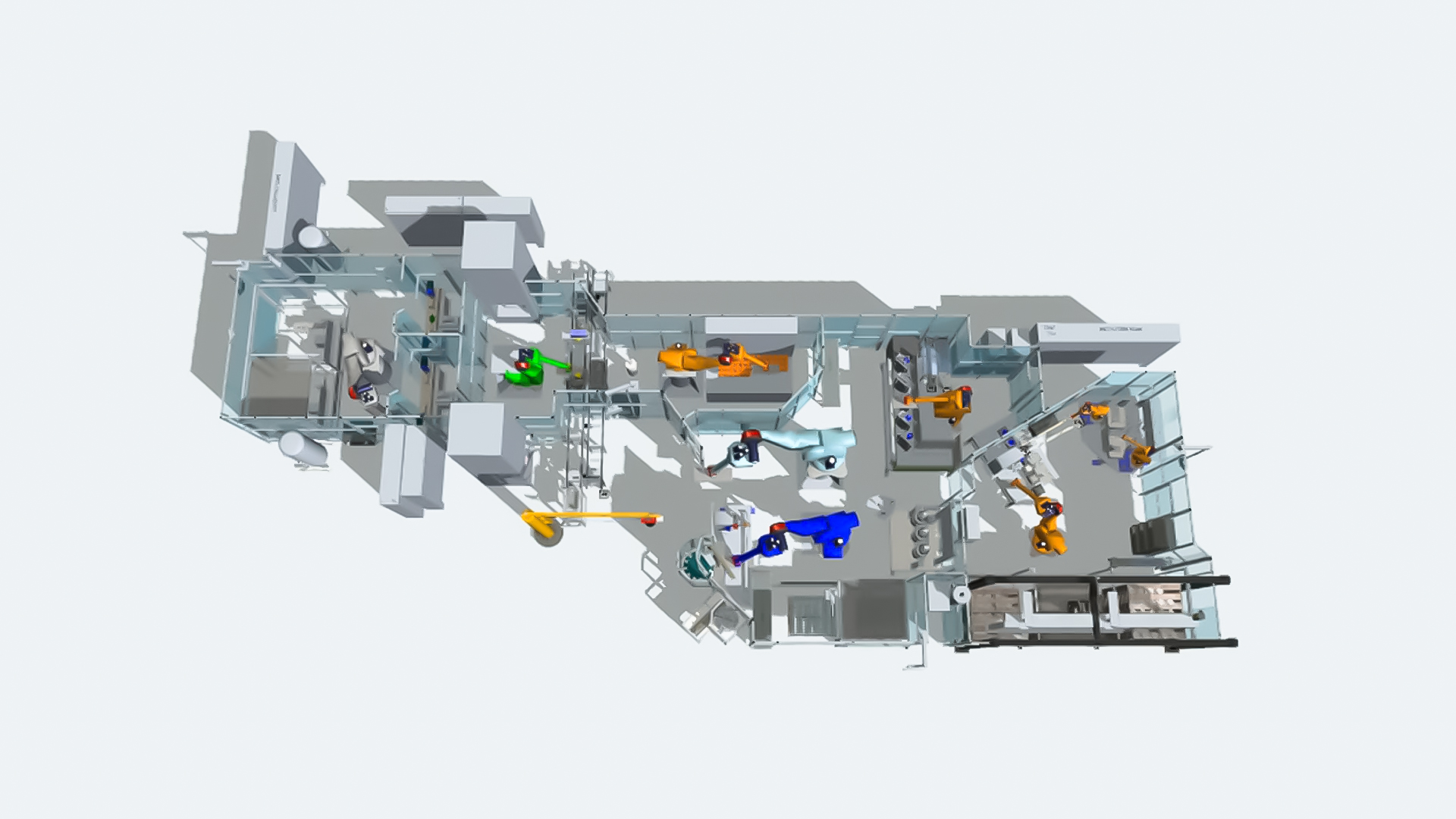

Practical examples include the full testing of robotic cells, complex assembly lines, and integrated multi-technology systems.

Flow simulation, a predictive view of the layout

Material flow simulation allows for the creation of a virtual model of the entire production line, starting directly from the layout. This digital environment accurately simulates system behavior, enabling analysis and flow optimization before the physical installation.

Core features include:

- Simulation of real-world events such as breakdowns, downtimes, and interlock logic;

- Implementation of robots, dynamic buffers, control logic, and component interaction;

- Integration with a PLC/server communication module to test connectivity and simulate hardware-in-the-loop scenarios.

Expected outcomes:

- Performance evaluation in terms of throughput, efficiency, and cycle times;

- Early identification of bottlenecks and flow issues;

- Validation of control logic and resource optimization.

Digital Twin and Artificial Intelligence, the future is already at work

IMA AUTOMATION has integrated the Digital Twin concept with an advanced virtual vision system that allows photos and videos to be captured directly from the digital twin, then faithfully replicated in the real world. This approach provides even more accurate analysis of machine behavior and visual validation of functionalities, with a strong focus on quality.

At the same time, reinforcement learning algorithms are being developed for robotic systems to test and optimize vision procedures. This enables autonomous learning by the system, improving recognition capabilities and final product quality control.

Immersive Virtual Training, putting the operator at the center

An additional step toward full digitalization is the ongoing experimentation with immersive training in virtual reality, using intelligent haptic gloves. This technology allows operators to interact with the virtual machine by performing the same operations required in real life, receiving real-time feedback and learning step-by-step. The result is increased operational awareness and reduced on-site training time.

IMA AUTOMATION continues to drive digital transformation by focusing on integrated, predictive, and intelligent solutions for the automation of tomorrow. In one of the most recent initiatives on these topics, Luca Emiliani, Team Leader Virtual Commissioning Engineer, delivered a lecture titled "Automation Software and Design Patterns" at the University of Bologna, to students of the Master's program in Automation Engineering. A concrete opportunity to share the vision of a more virtual, connected, and quality-oriented automation.