THE PROJECT

Robotic Handling of Liquids for High-Performance Industrial Applications

In this project, innovative motion planning and control techniques will be developed and tested for the robotic manipulation and co-manipulation of liquid containers subjected to highly dynamic spatial motions. In the field of automatic packaging machines, it is often required to handle liquids while minimizing the oscillation of the liquid inside the container (the so-called “sloshing” motion). The possibility of manipulating several cylindrical containers simultaneously by a single robot or a single container by two robots will be explored, in both prehensile and non-prehensile configurations. In the former, the robots firmly grasp the liquid containers, whereas in the latter the containers are simply placed on a tray.

Project Overview

Duration: 18 months (December 2023 – May 2025)

Partners: 5 organizations across Italy

Key Goals and Technological Developments

Matrix aims at developing and testing:

- motion planning and control techniques for the prehensile handling of liquid containers for highly dynamical spatial motions; in particular, the possibility of manipulating several cylindrical containers at the same time by a single robot or of a single container by two robots will be explored, as well as the possibility of manipulating rectangular trays, through the development of suitable computationally-efficient sloshing models.

- motion planning and control techniques for the non-prehensile manipulation of objects or liquid containers, for highly-dynamical spatial motions, even of several containers simultaneously.

The software platform developed by Matrix will be demonstrated in an industrially relevant environment by implementing different use cases.

IMA Use Case

In the handling of TUBs containing vials with pharmaceutical liquid, it is necessary to ensure that the product does not spread onto the walls of the vial. This requirement is increasingly difficult to guarantee as the required speeds increase and with the various sizes of vials/syringes that the market demands for production.

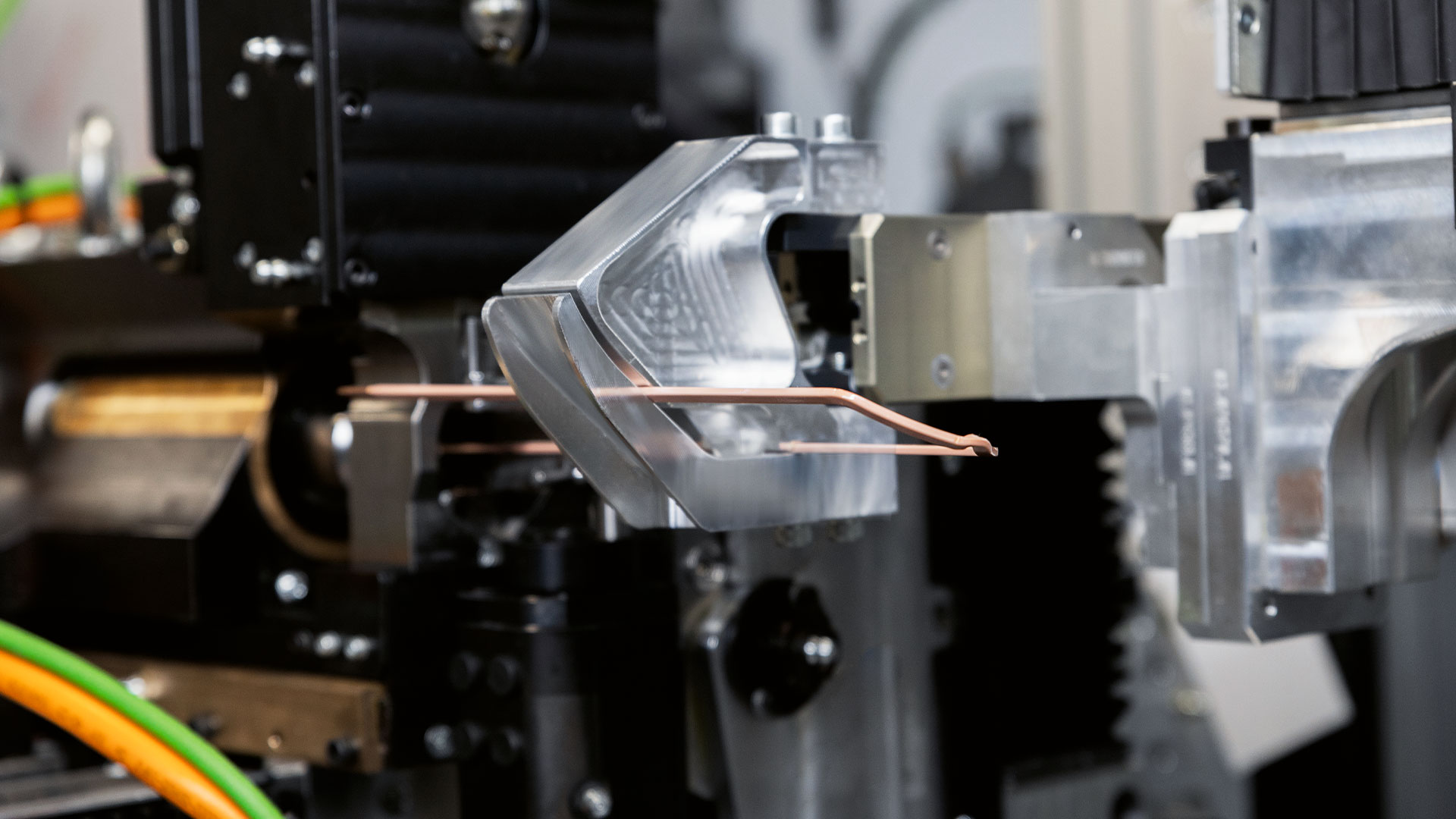

Additionally, the project will include a feasibility study to extend the applicability of anti-sloshing algorithms to the production process of hairpin-type electric motors. In this case, the possibility of using the developed technologies to compensate for the oscillations produced by the vibration of copper wires subjected to strong stresses due to the speed of handling systems will be evaluated.