Contact Lens Solutions

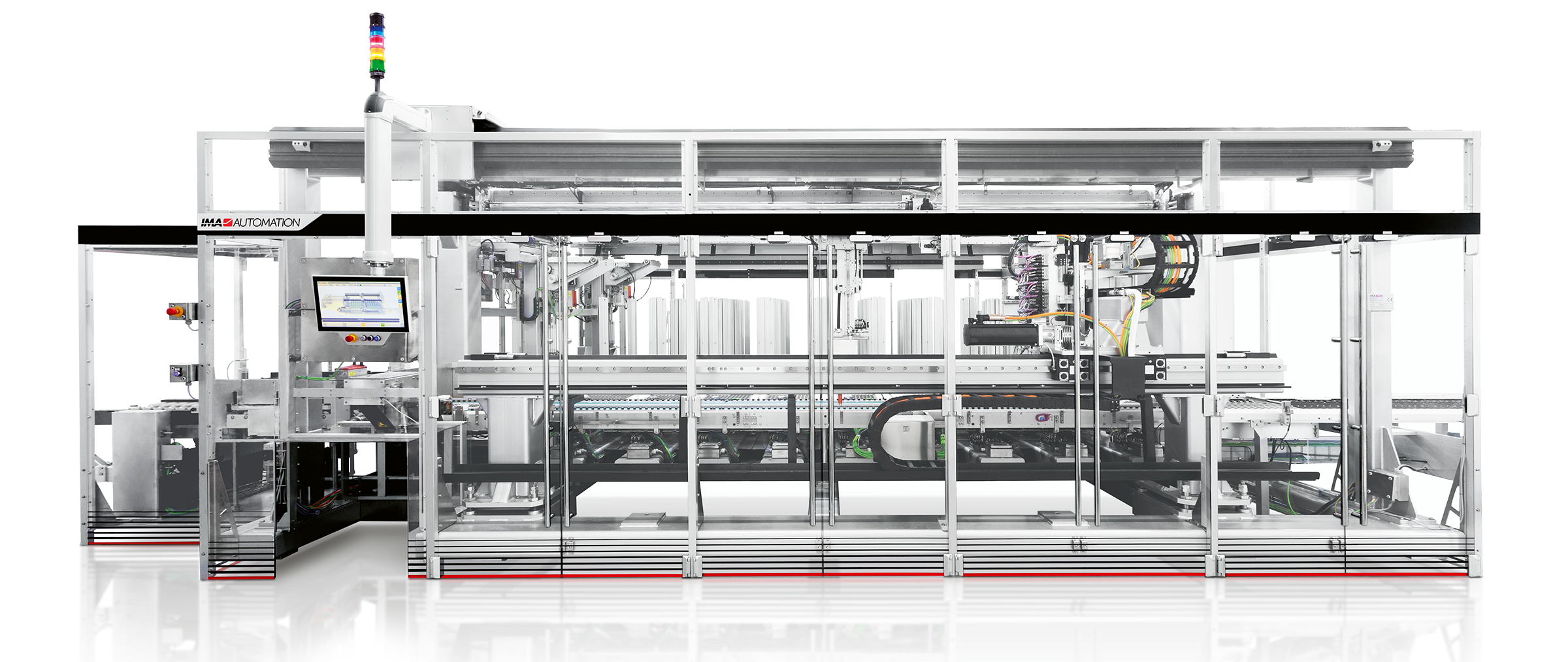

Turnkey solutions for contact lenses

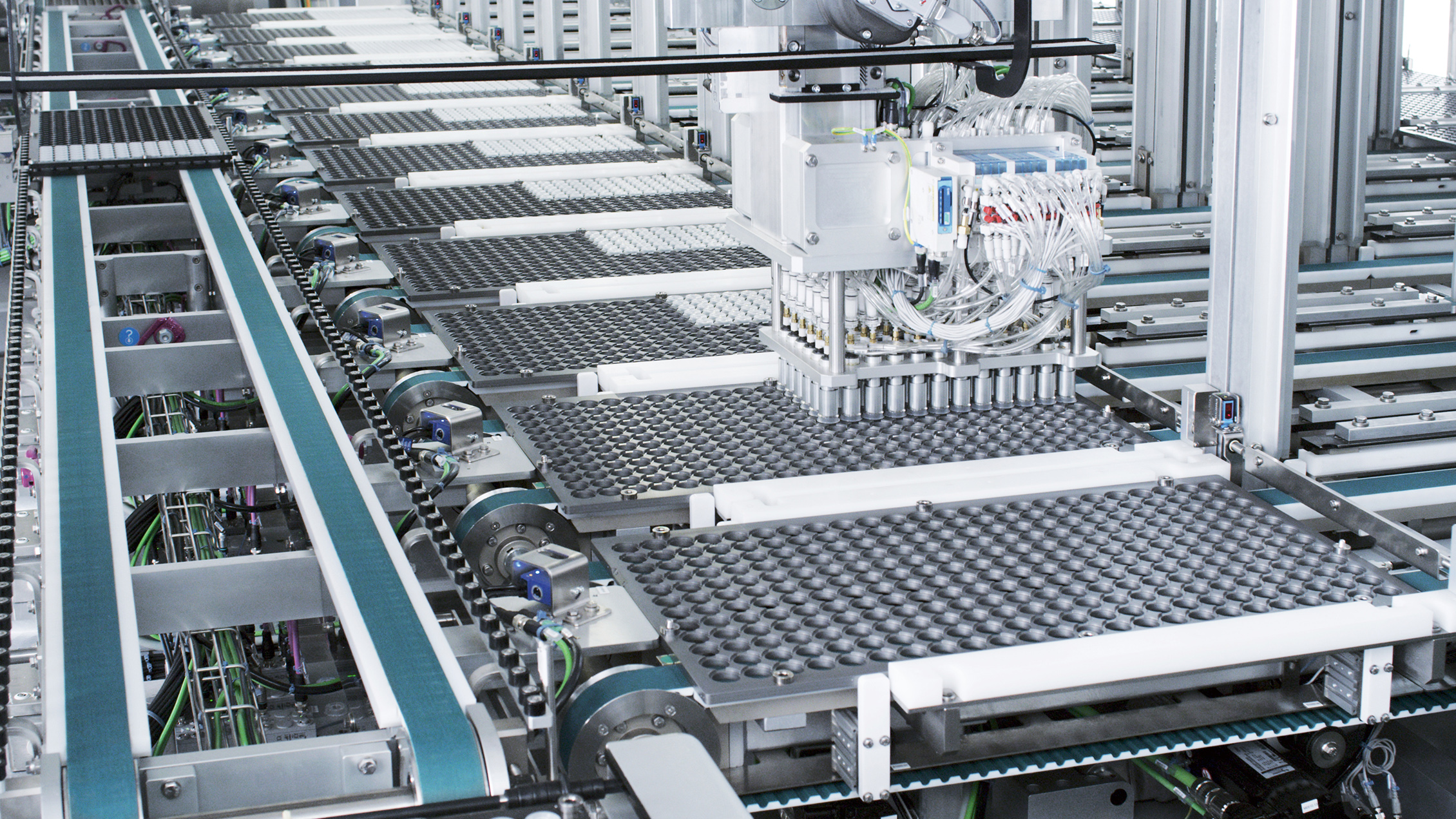

IMA MED-TECH has developed fully customized lines for the processing and handling of contact lenses and blister packaging, as well as for the assembly of ophthalmic inserters.

Designing space saving and high performance contact lens manufacturing lines, IMA MED-TECH provides total control of the contact lens manufacturing process for colored, daily or semi permanent contact lenses.

Processing, handling and packaging solutions

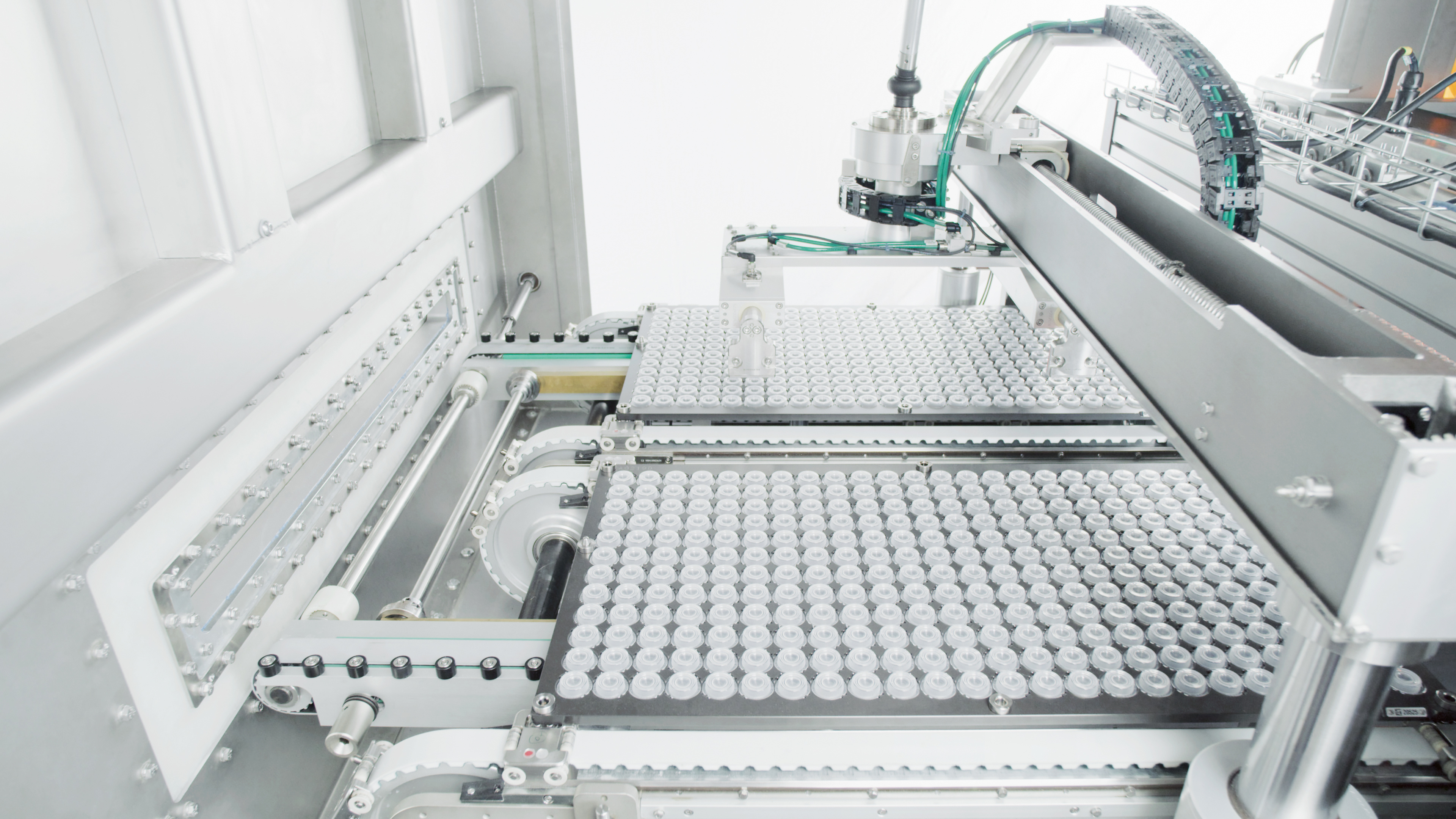

Complete Lines

Lines are designed to implement robotizing, filling, laser and inspection systems, in order to duly execute lens releasing, washing and packaging operations. This also ensures high versatility in the handling of different sizes of lenses, thanks to quick mechanical and control changeovers.

- PROCESSING AND HANDLING

- PRIMARY PACKAGING

- SECONDARY PACKAGING

High flexibility and modularity

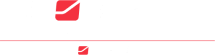

IMA MED-TECH tailor made solutions for contact lenses are able to integrate modules dedicated to different tasks , such as lens inspection, lens hydration, packaging, sealing , laser marking and the automatic inspection of packaging materials.

Lot traceability has also been a primary focus in designing our machinery according to the highest medical industry standards.

- DEMOLDING

- MONOMER DOSING & CURING

- LENS MANIPULATION

- PRIMARY AND SECONDARY PACKAGING

From processing to packaging

Process solutions from lens mold production (demolding, storing quality control ), up to mold treatments and monomer dosing and curing.

Packaging solutions for lens release from mold, mold purge, lens hydration, blister filling and sealing.