Assembly of Injectables

IMA MED-TECH specializes in the assembly of pens and auto-injectors, covering automatic denesting systems, dosing mechanisms, power-pack assembly, and drug manipulation.

STANDARD SOLUTIONS

Efficient assembly systems for commercially available devices, utilizing advanced technology and quick delivery.

CUSTOM SOLUTIONS

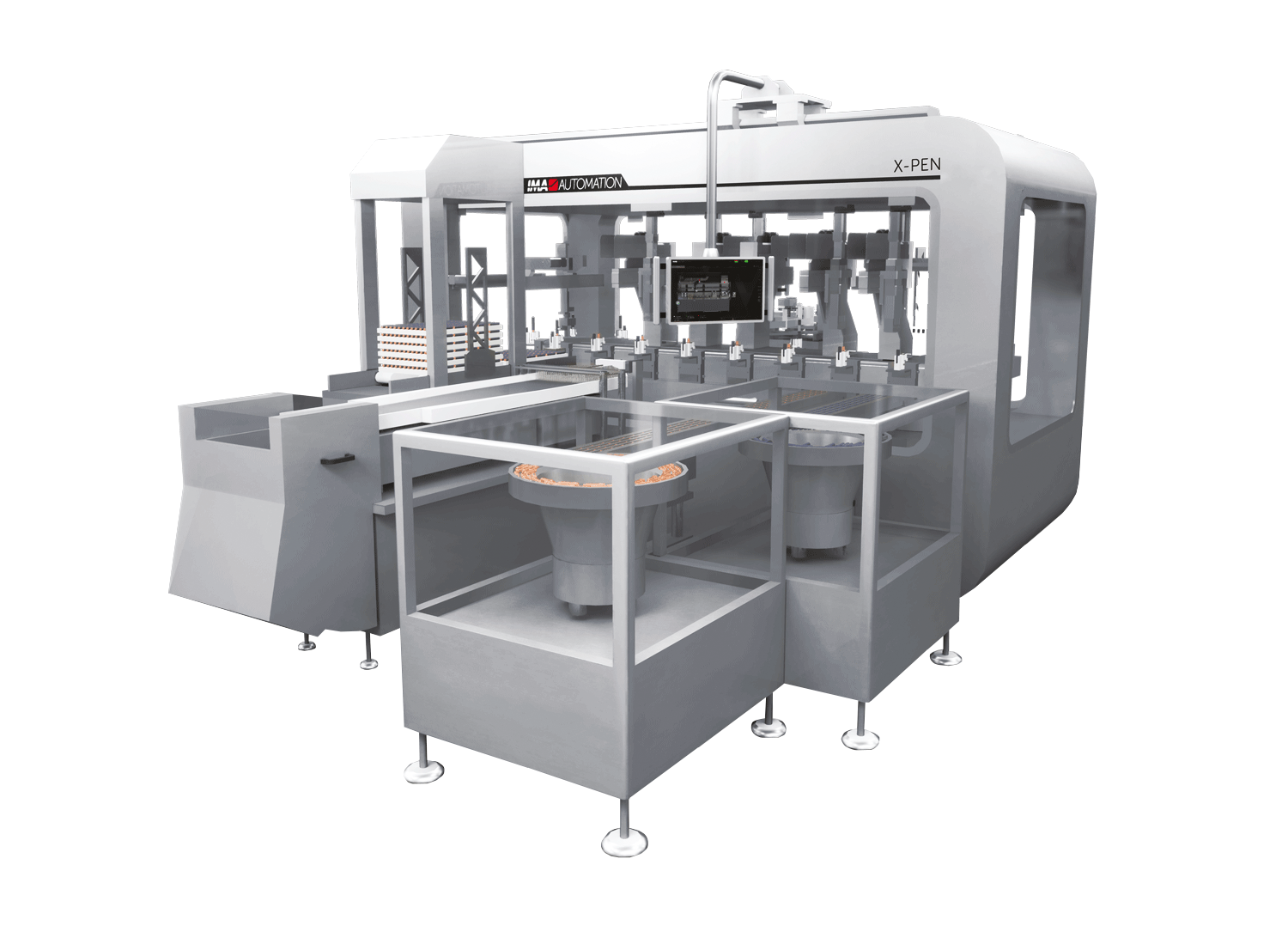

Tailored assembly options that adapt to specific device requirements for flexibility and optimal performance.

PEN SYSTEMS & AUTOINJECTORS

Precise solutions for pre- and final assembly, including testing of electronic components.

SYRINGES

Assembly and marking of safety devices and pre-filled syringes using automatic machines.

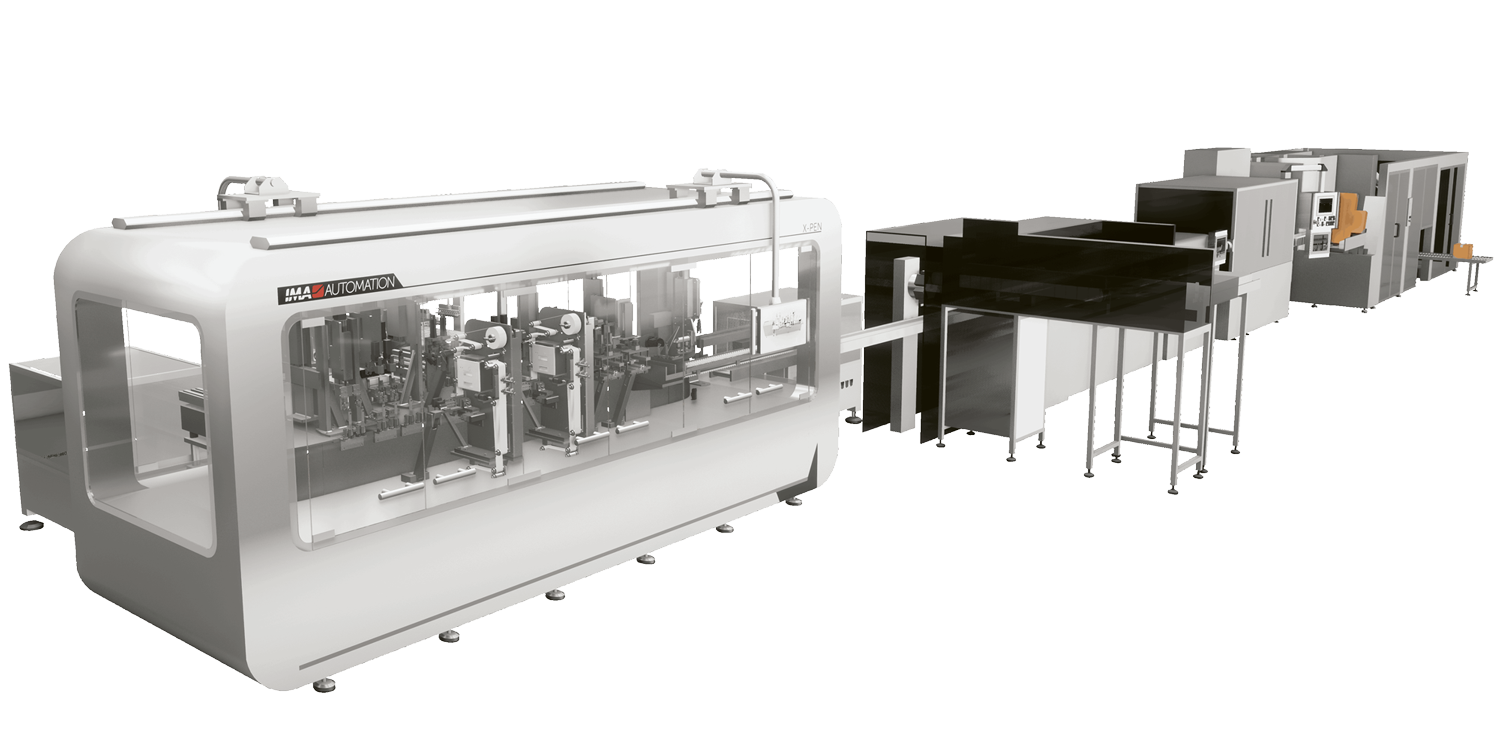

Standard assembly solutions

A IMA MED-TECH MODULAR PLATFORM APPROACH FOR PENS, AUTOINJECTORS AND NEEDLE SAFETY DEVICES FINAL ASSEMBLY SYSTEMS.

With latest robust technologies, labelling as standard, quick time-to-market, compact design, standard machine bases and market leading ROI, our systems bring state-of-the-art technology to your fingertips.

Advanced Modularity & Multi-Variant Manufacturing

Flexible Assembly

Machines assemble standard pens and auto-injectors with reduced changeover times, achieving outputs of up to 160 pieces per minute, including integrated labeling.

Custom Configuration

Machines can be tailored to customer needs, integrating upstream and downstream processes like cartridge loading and secondary packaging.

Magnetic Transport System

A modular, efficient and low-maintenance transport system based on independent movers, offering flexibility, speed and synchronization across production stations.

- Low noise, high repeatability, and full process synchronization.

Advanced Technology

Electrical Pick and Place

Activated by PLC, these modules reduce air consumption and allow precise control of vertical and horizontal motions.

Press Force System

Controlled press operations using force-distance measurements to meet device manufacturer specifications.

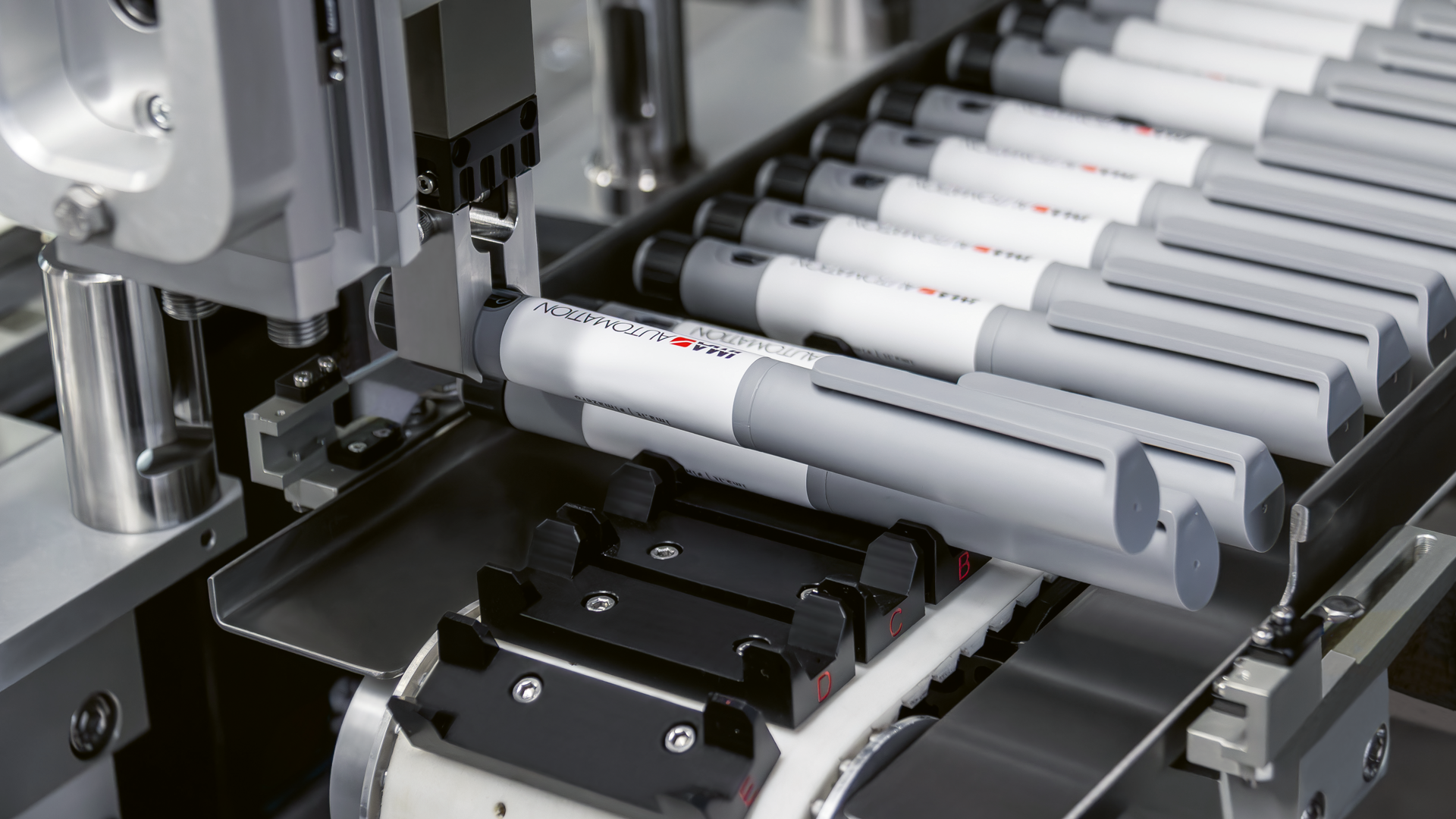

Precise Label Application

Labels are applied with high precision using a pick & place module and roller system. Options include automatic or manual changeovers and integration of label printing, OCR checks and tracking systems for full traceability.

Advanced Quality

Quality & Control

Devices are inspected for critical assembly attributes using mechanical and vision systems with inspection speeds under 80ms. The vision system is triggered by the Linear Magnetic Transport System (LMTS) for precise positioning.

Efficient Inspection

"On the fly" vision inspection is performed during product transfer at a controlled speed.

Standard Equipment Benefits

Off-the-shelf equipment offers reduced lead times, smaller footprint, and enhanced efficiency and reliability.

Advanced Efficiency

All key processes integrated

Processes are at the heart of repeatable and robust assemblies. Below are some of the many possibilities, all fully integrated into IMA MED-TECH standard solutions machine.

- CARTRIDGE, CAP & CARTRIDGE HOLDER FEEDING

- PFS HANDLING WITH NO GLASS-TO-GLASS CONTACT

- ELECTRICAL PICK & PLACE

- CARTRIDGE/PFS VISION INSPECTION

- PRIMING

- PRESS FORCE SYSTEM

- LABELLING

- FUNCTIONAL TESTING

- 2D MATRIX CODE PRINTING & INSPECTION

- ON-THE-FLY VISION

- TRAY LOADING

- PALLETISING

- MANUAL LOADING

Advanced Connectivity

User friendly information, minimal MTTC (Mean Time to Correct), 2D & 3D images, multi-language descriptions. Data driven services for production with SENTINEL platform. Enabling to monitor autonomously machine conditions in real time, collecting raw data and translating them into meaningful and valuable information.

IMA Group standard HMI concept

-

SIMPLE, MODULAR SYSTEMS

-

STANDARD BASES

-

CUSTOMISABLE

-

HMI WITH SLIDING MOVEMENT TO IMPROVE ERGONOMICS

-

CROSS-PLATFORM CLIENTS

-

OPC/UA AS CORE TECHNOLOGY

Turnkey Solutions

Assembly and packaging integrated solutions

IMA is your ‘all-in-one’ provider for low, medium and high output assembly and packaging solutions.

Turnkey lines are customized dependent on customer specifications, such as product type (blister/carton), label type and output.