Watchmaking

High-Precision Assembly Solutions

IMA AUTOMATION has deep roots in the watchmaking industry. We have built-up a wide experience and a unique know-how in the automation of watchmaking processes, as well as in the precision assembly, the handling and the measurement of delicate watch components.

High-Precision Assembly Solutions

IMA AUTOMATION has deep roots in the watchmaking industry. We have built-up a wide experience and a unique know-how in the automation of watchmaking processes, as well as in the precision assembly, the handling and the measurement of delicate watch components.

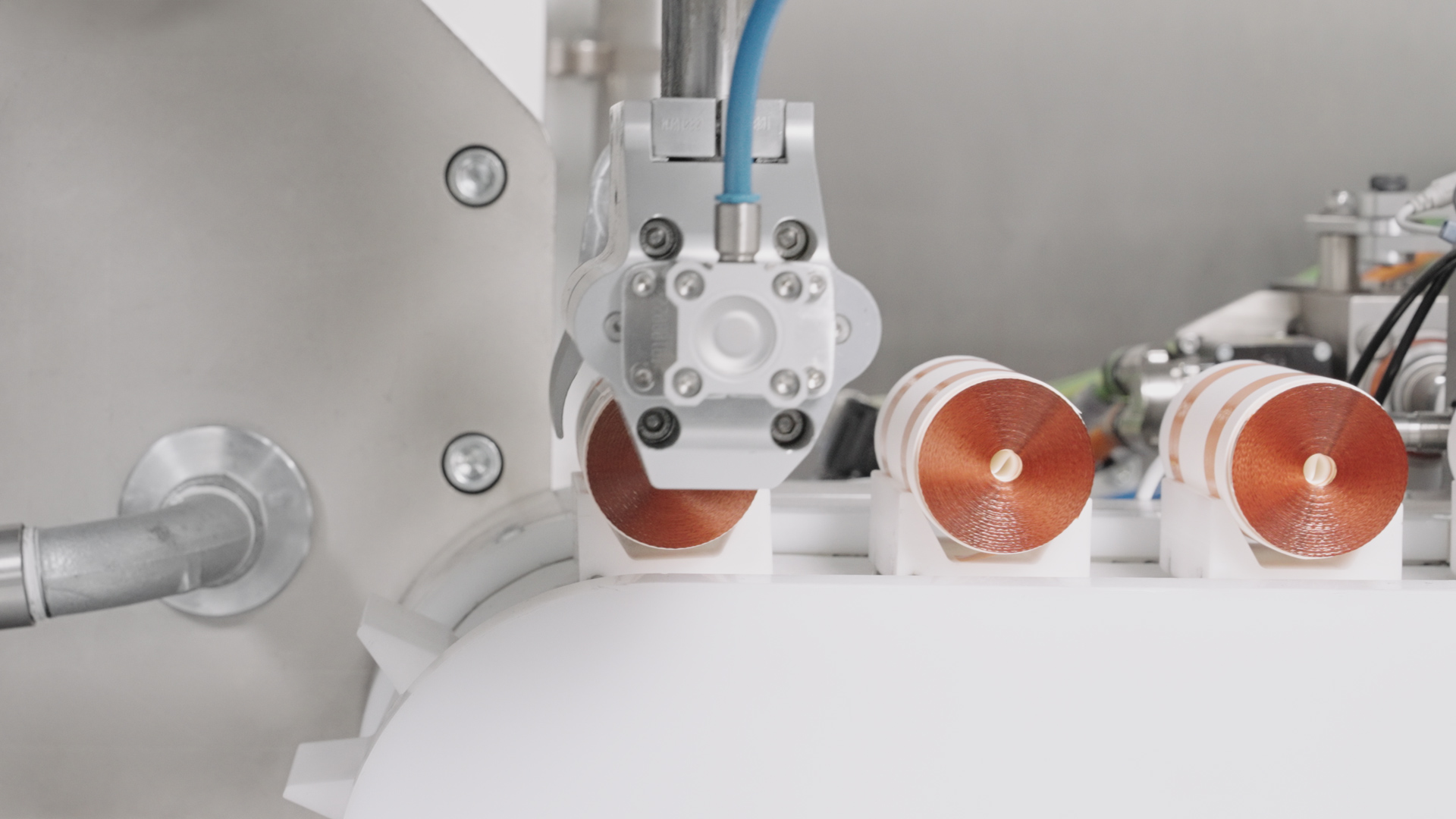

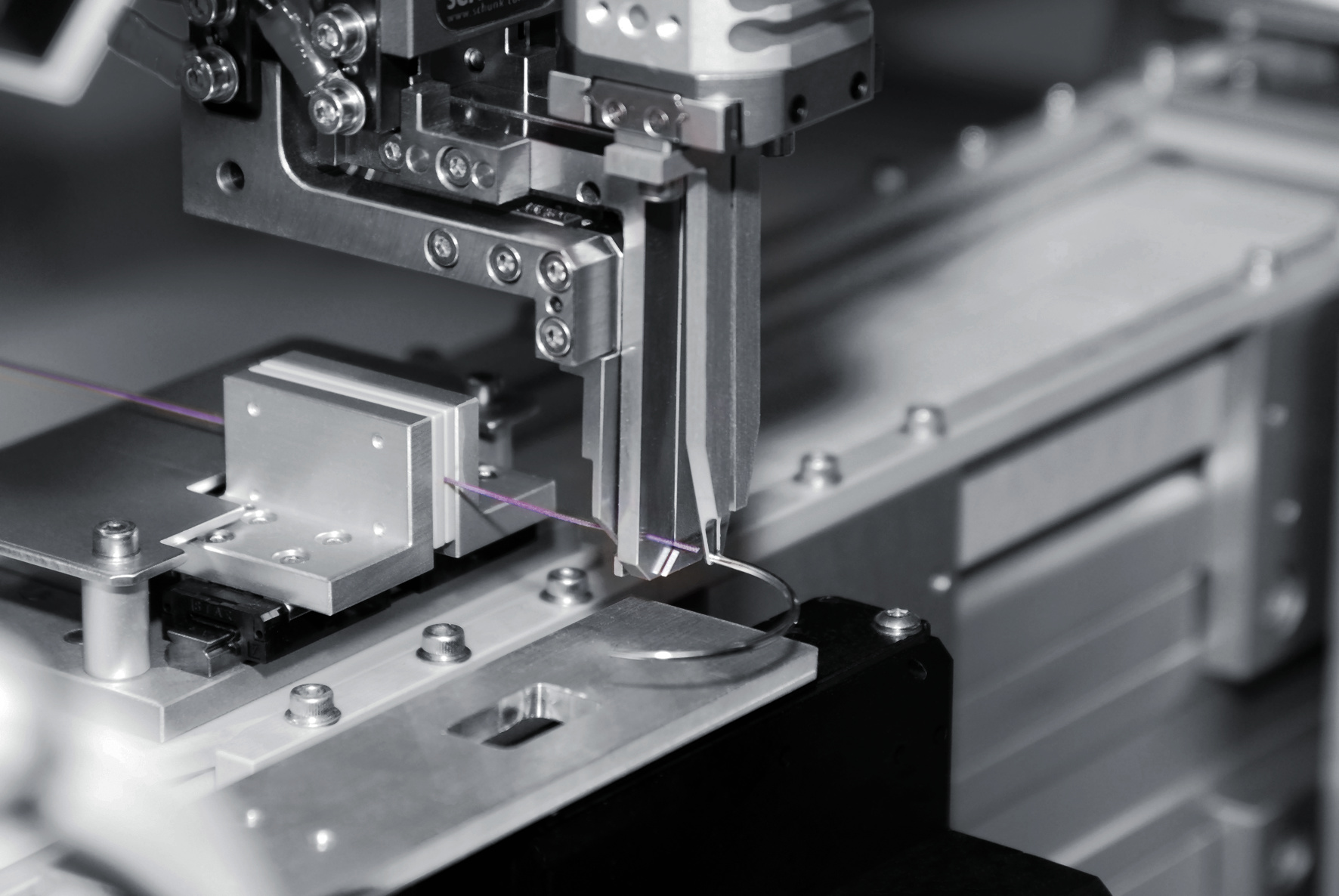

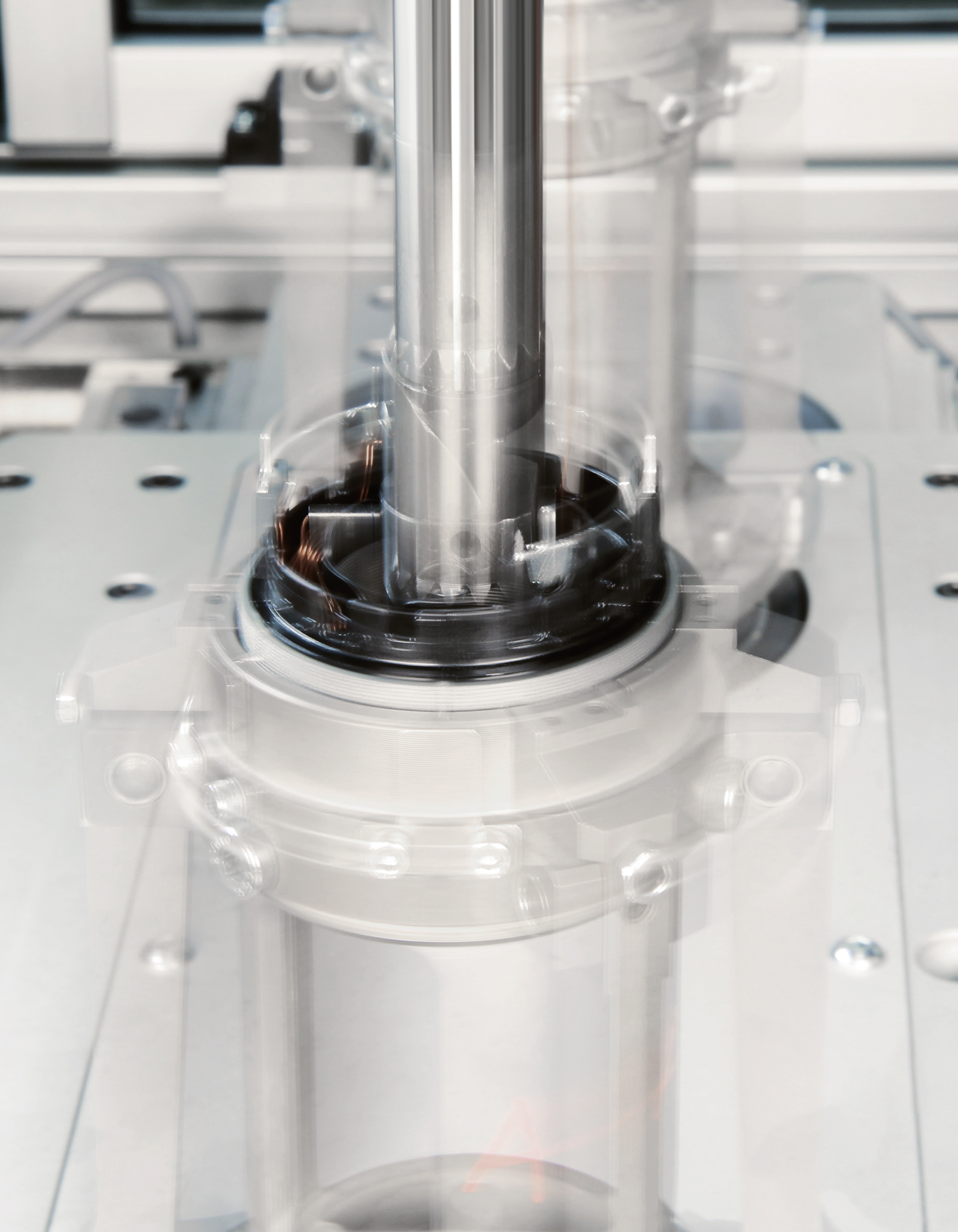

Garnissage

Strong expertise in manipulation and assembly of delicate watch parts. Press-fitting and insertion of miniature components onto thin or delicate fixtures. Compensation of high coefficients of deformation.

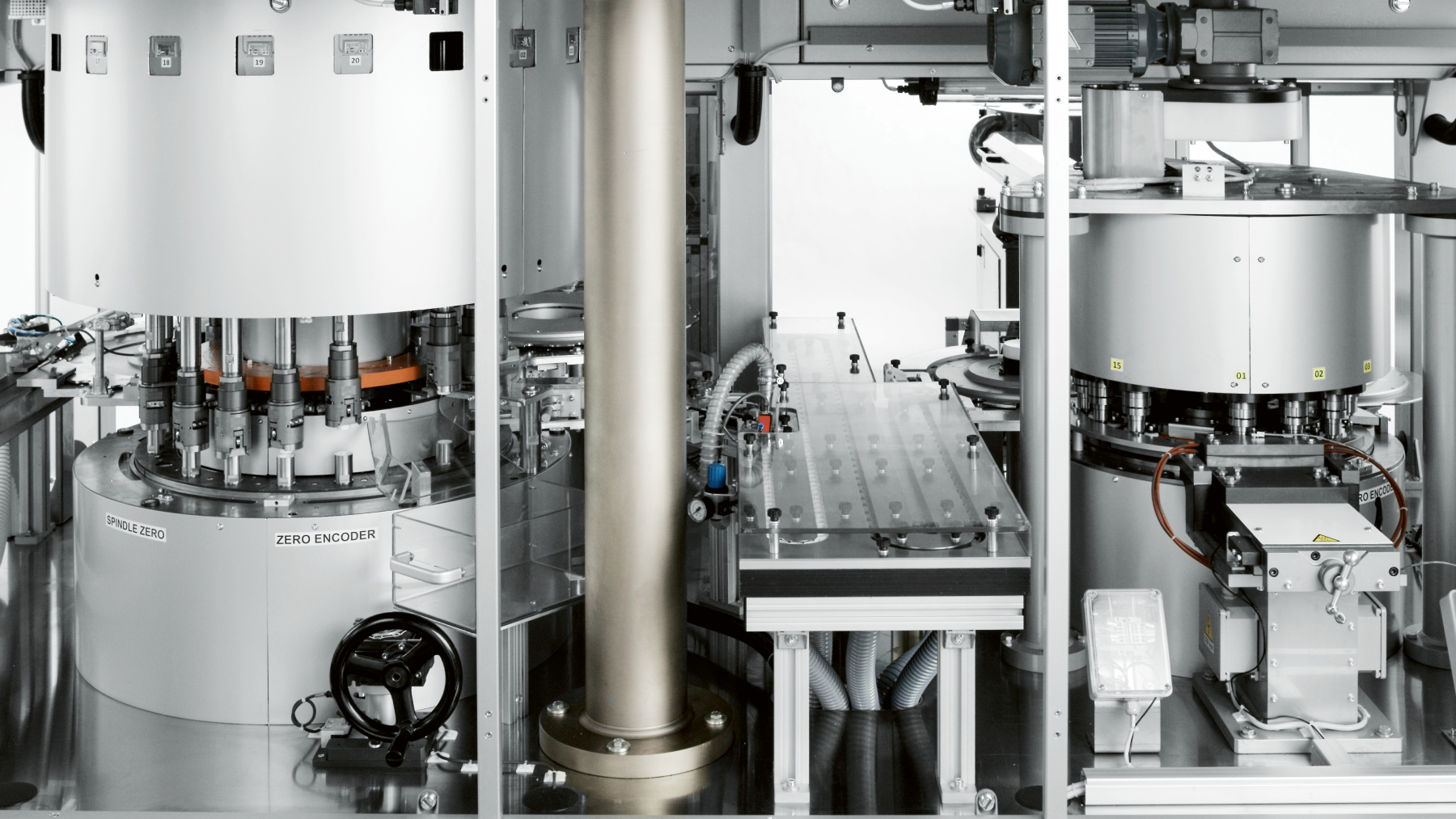

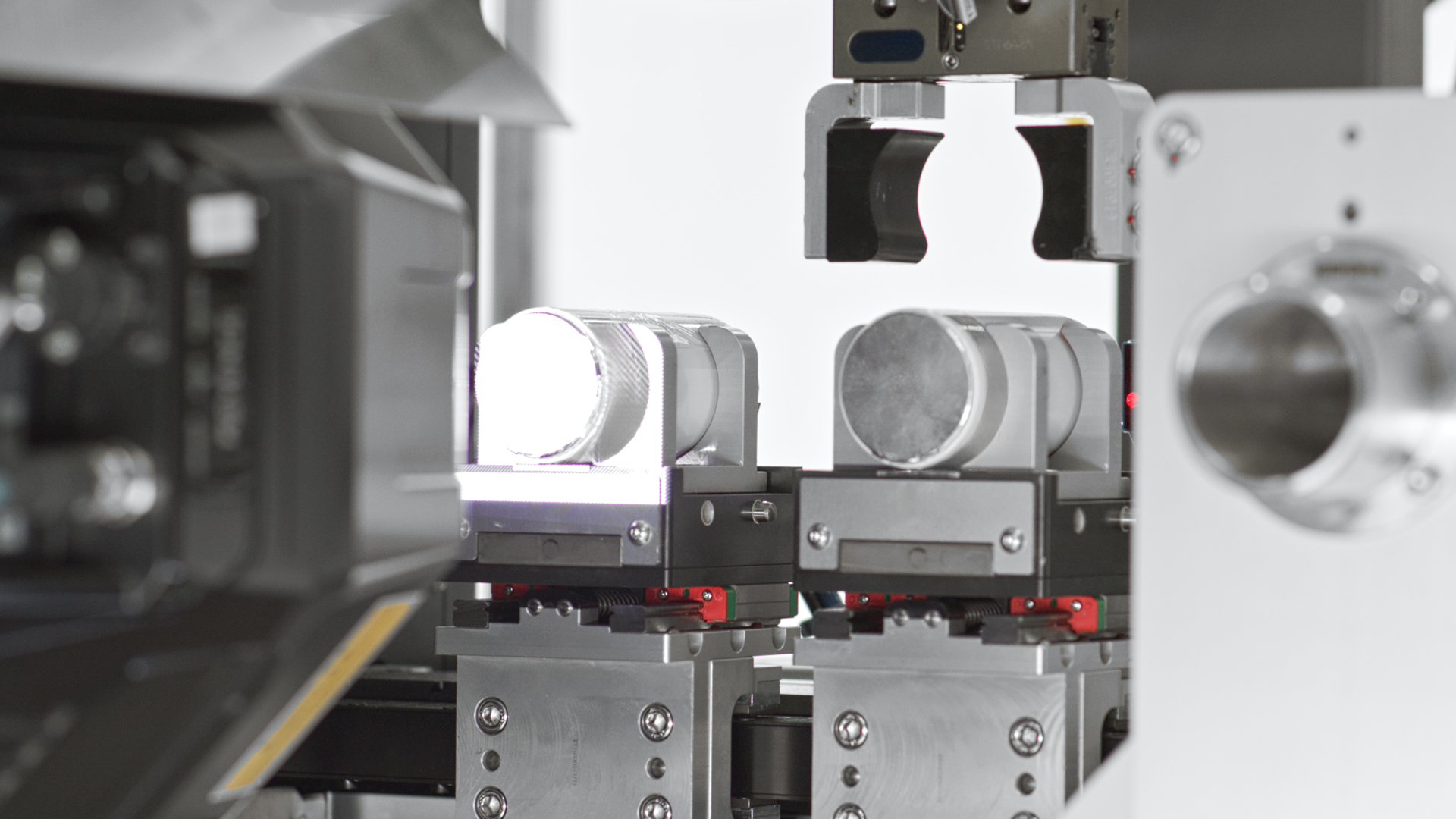

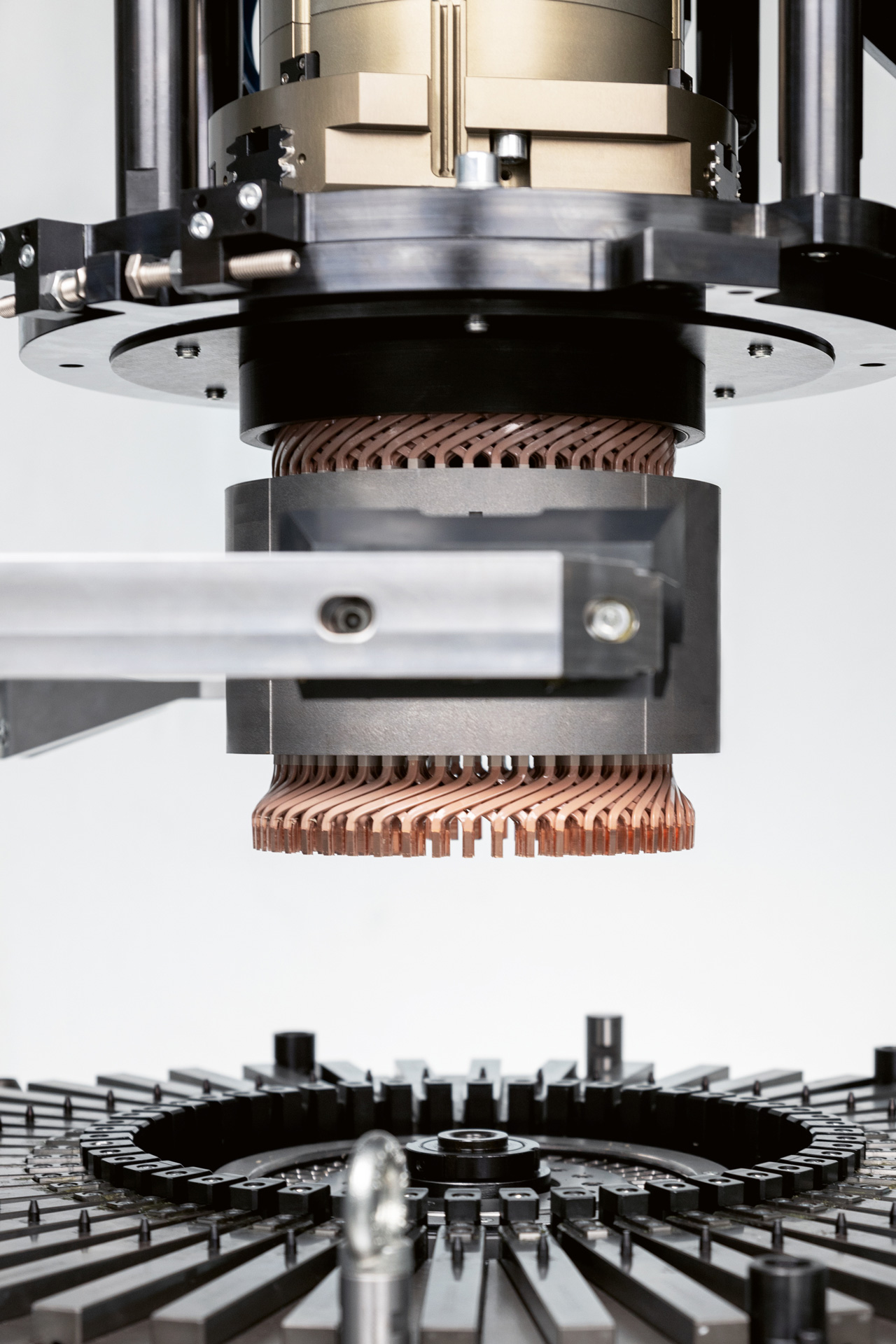

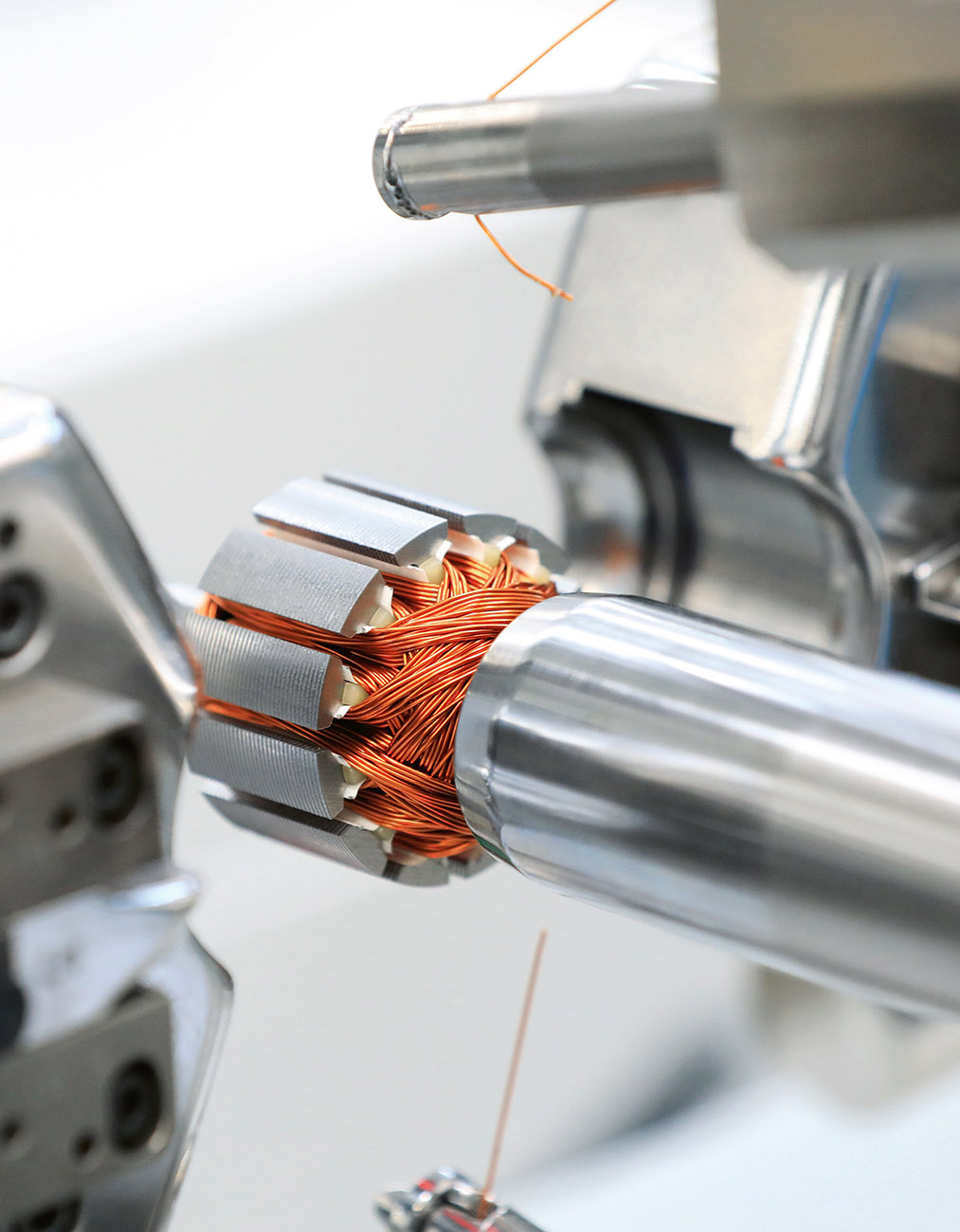

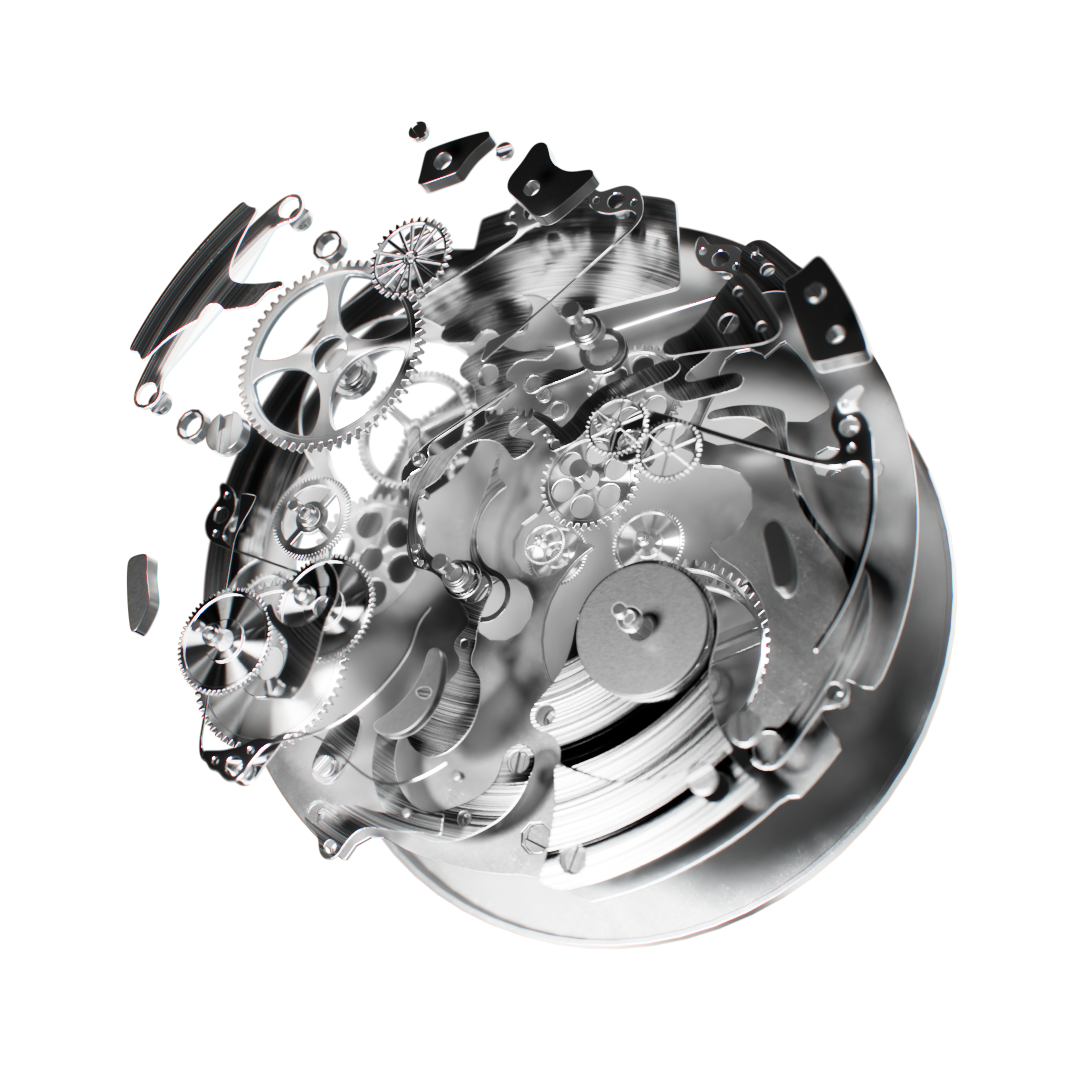

Watch Movements

Strong expertise in assembly of complete watch movements and other watchmaking mechanisms, such as gears, balance pallet, springs and barrel.

Watch Heads

External parts (habillage) laser for engraving and cutting sapphires Testing equipment, such as contrôle de marche, remontage automatique and leak testing.

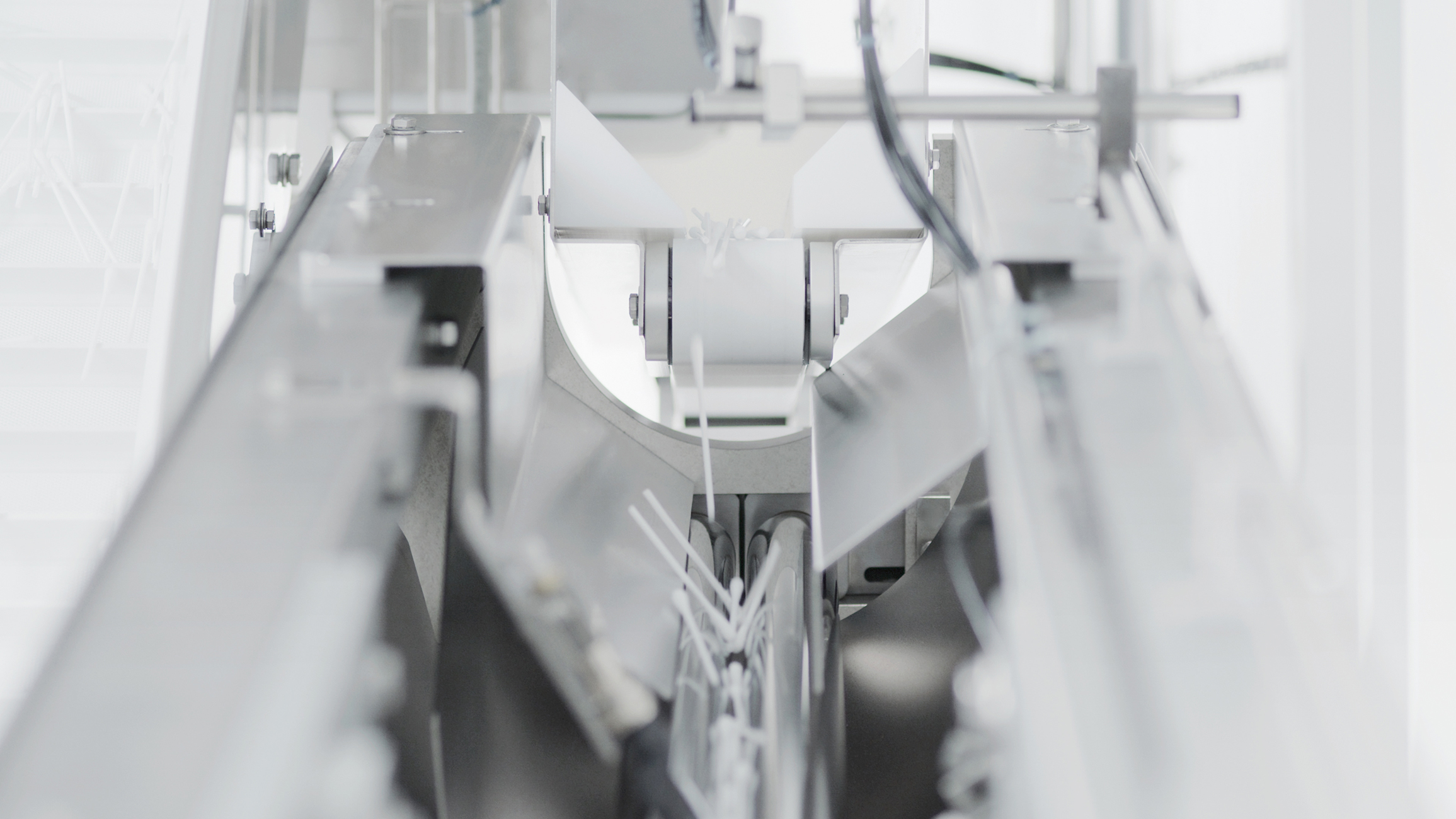

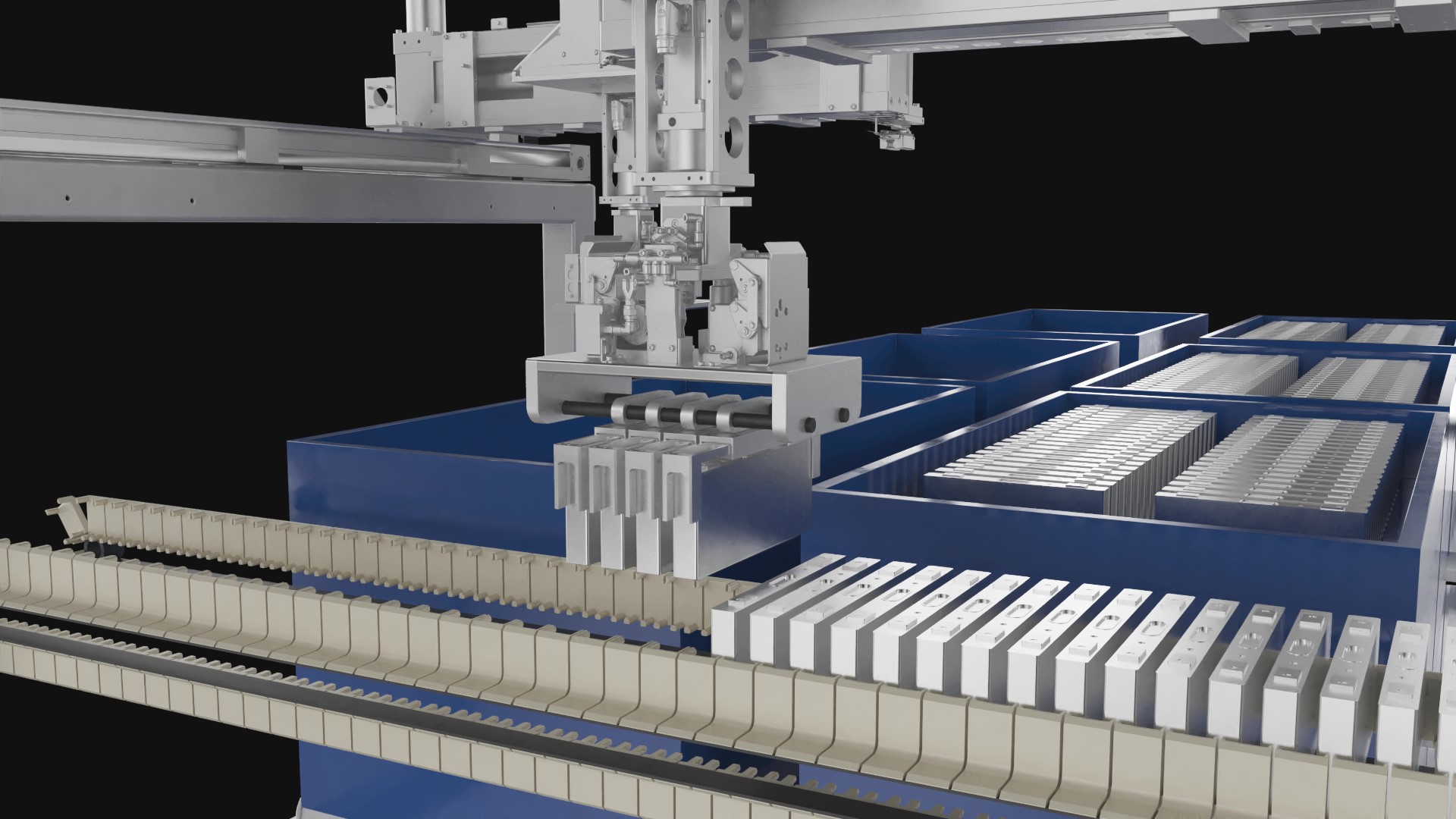

Bracelets

IMA AUTOMATION experience in watchmaking sector also includes the handling and assembly of metallic watch bracelet components, such as Screwing, Clearance adjustment, Dispensing and Laser welding.

Advanced

Caps & Closures

assembly from within

Caps & Closures

assembly from within

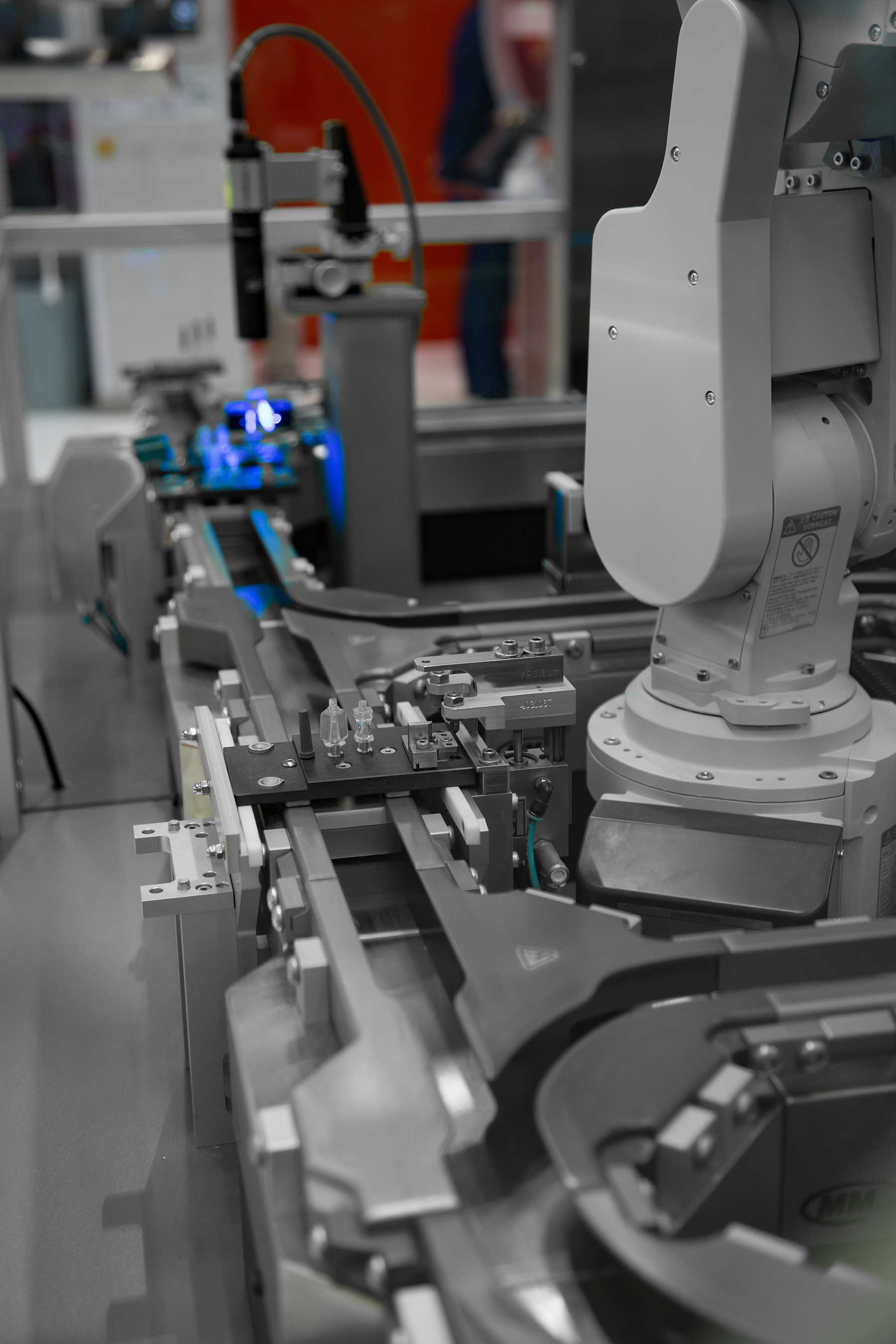

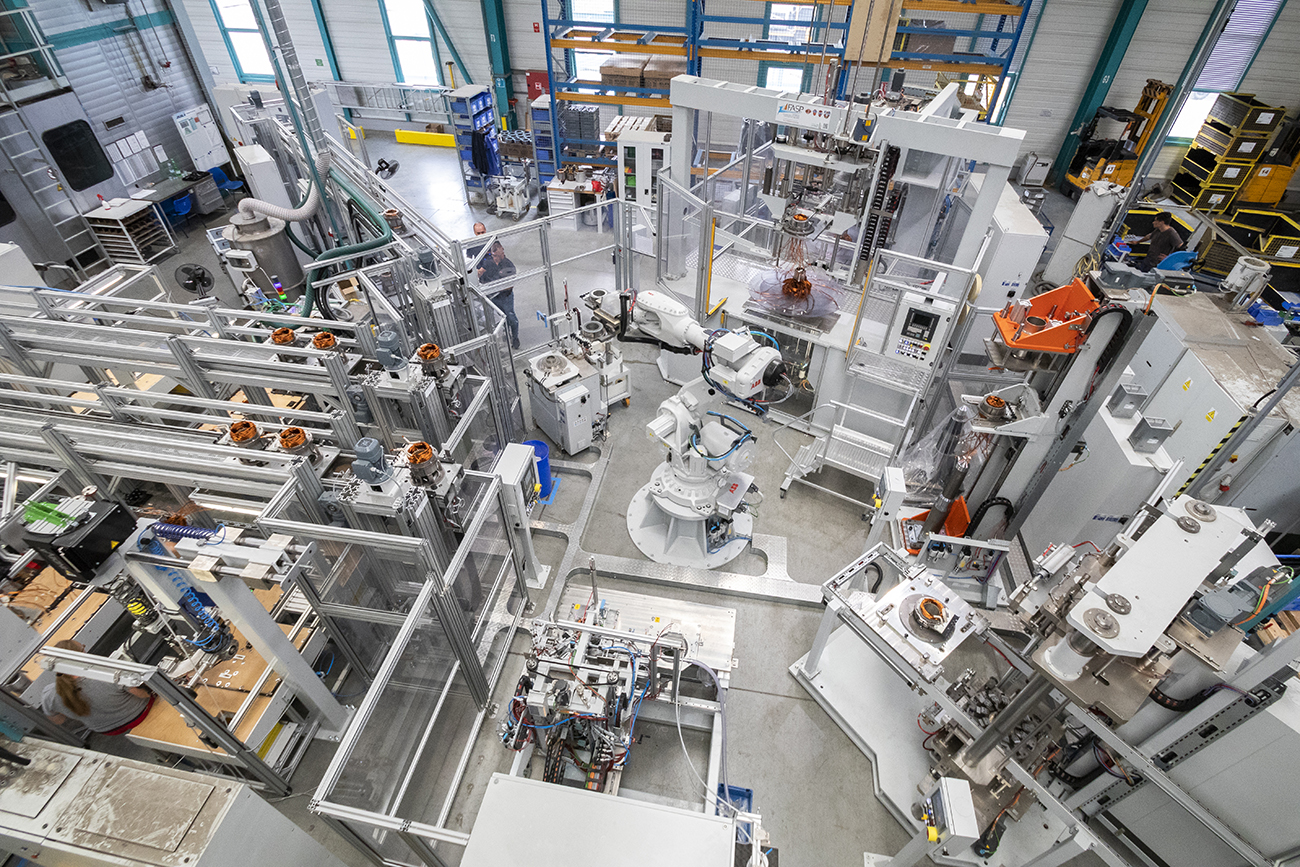

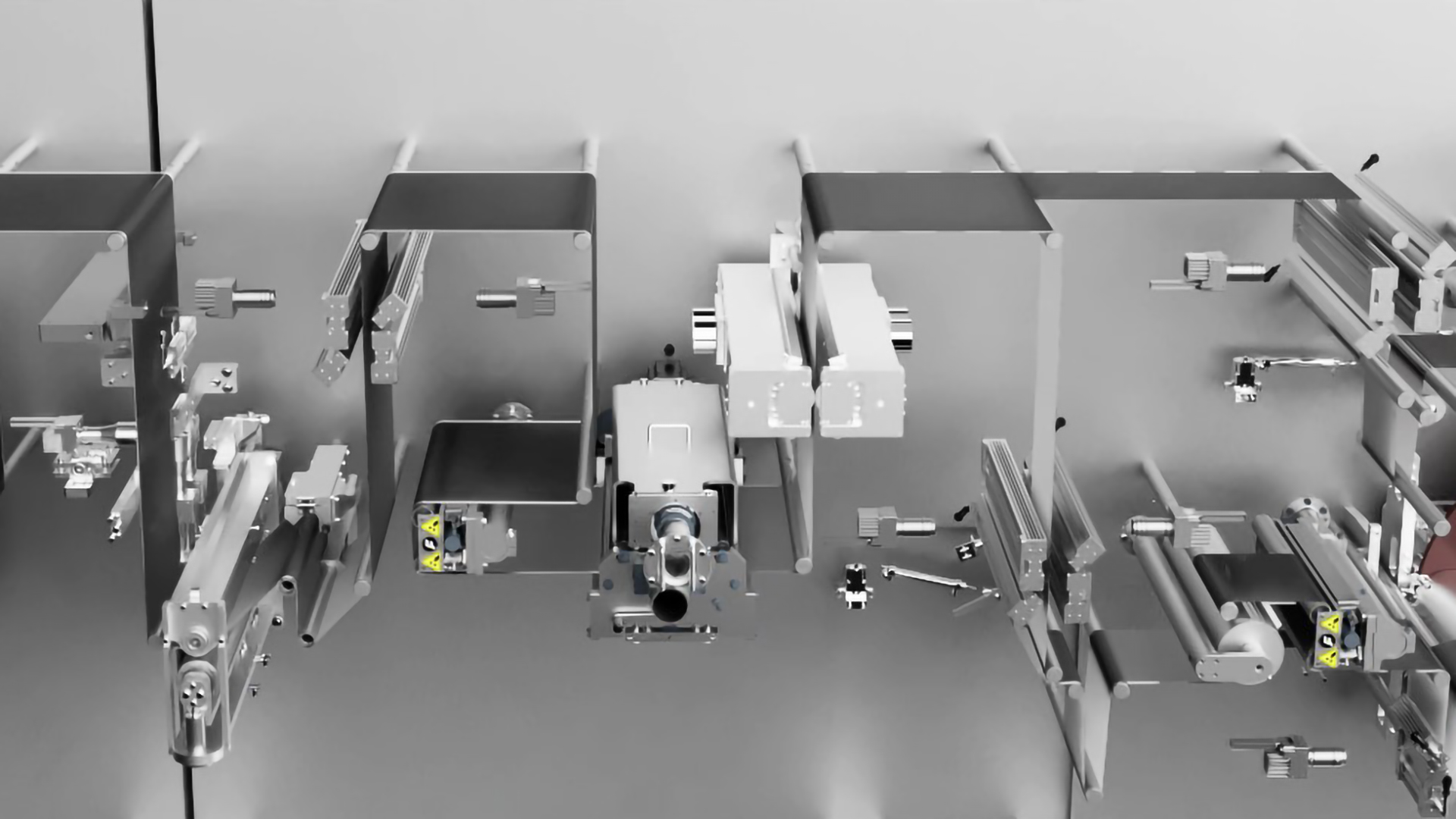

Technologies

A wide complete range of continuous and indexing platforms, as well as demolding and robotized solutions, which cover all needs of caps & closures assembly.

Each assembly system consists of a platform that forms the basis for a made to measure solution to satisfy specific needs. Stations and assembly technologies are added in accordance with customer requirements.