Electro-Mechanincs Assembly

Assembly solutions for electro-mechanics

IMA AUTOMATION can provide a wide range of cutting edge assembly solutions for electro-mechanic devices, from low to high volume, able to handle several types of critical processes:

- active alignment

- adhesive dispensing

- flex and pcb handling

- winding , leak testing

- vision inspection

- welding and soldering

A wide range of assembly solutions for electro mechanic devices:

- printing heads

- sensors

- actuators

- inkjet cartridges

- vision inspection

- connected devices

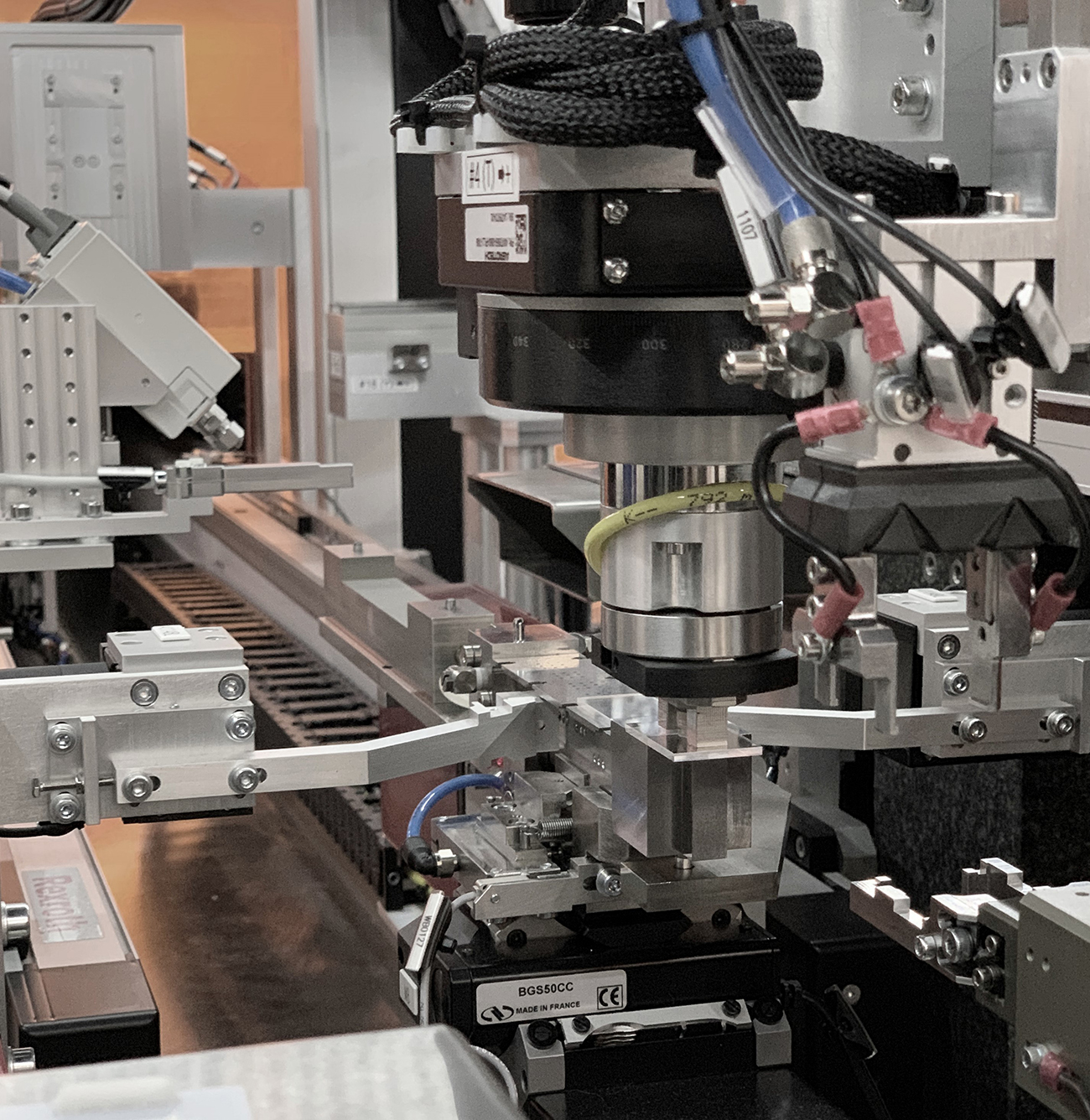

Printing head assembly

Custom platforms for automated high precision printing head assembly.

IMA AUTOMATION solutions are able to handle all critical subassemblies, such as:

- GRAPHITE BODY ASSEMBLY

- MEMS PLACEMENT

- PIEZO ACTUATORS

- LEDS AND CHIPS

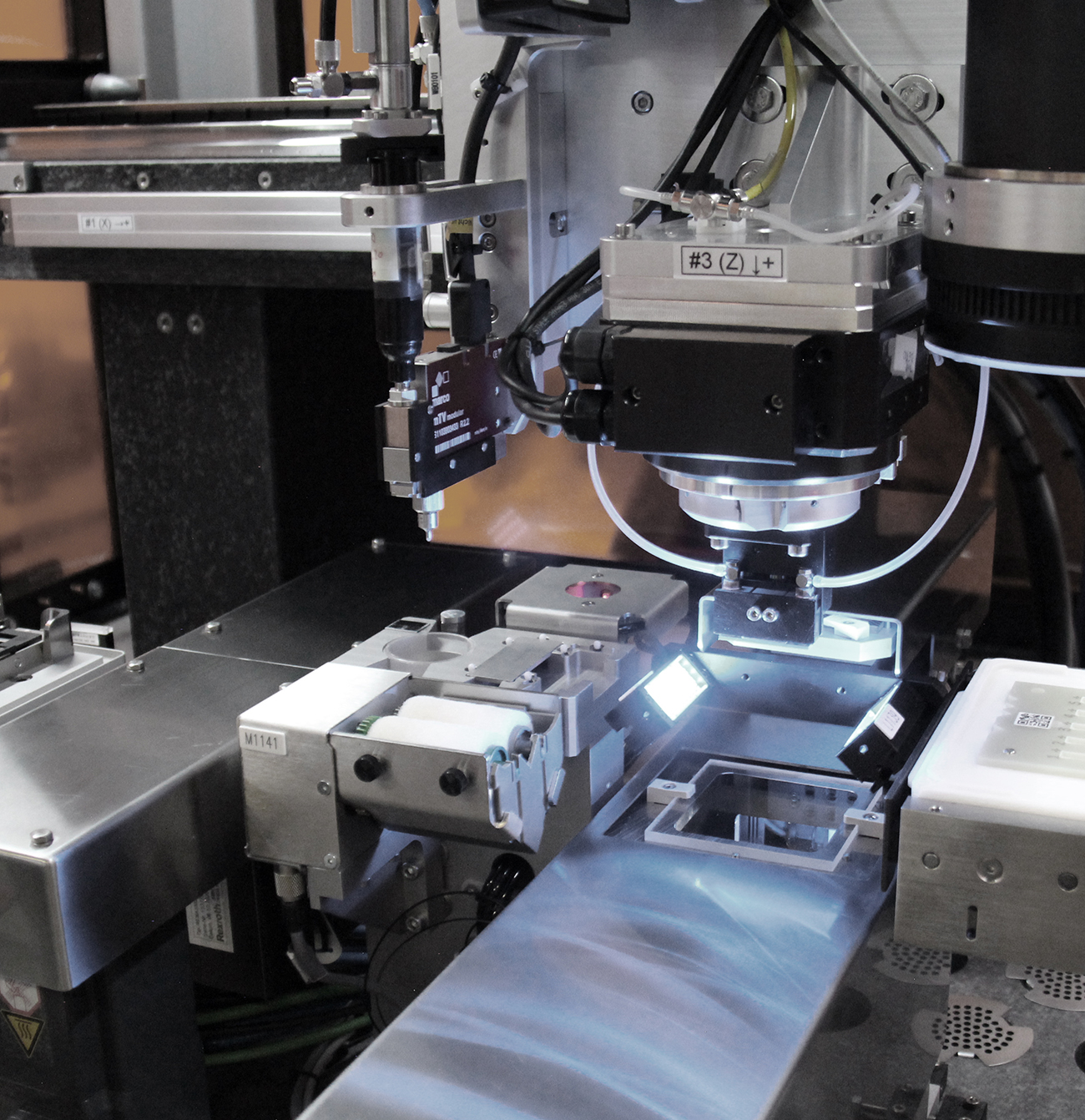

Sensor assembly

IMA AUTOMATION provides machines for assembly, testing and handling of sensors, besides services such as consulting, feasibility studies and prototypes.

- INDUCTIVE SENSORS

- OPTICAL SENSORS

- MEDICAL SENSORS

- MEMS AND PCB HANDLING

- INSPECTION OF PARTS AND SUBASSEMBLIES

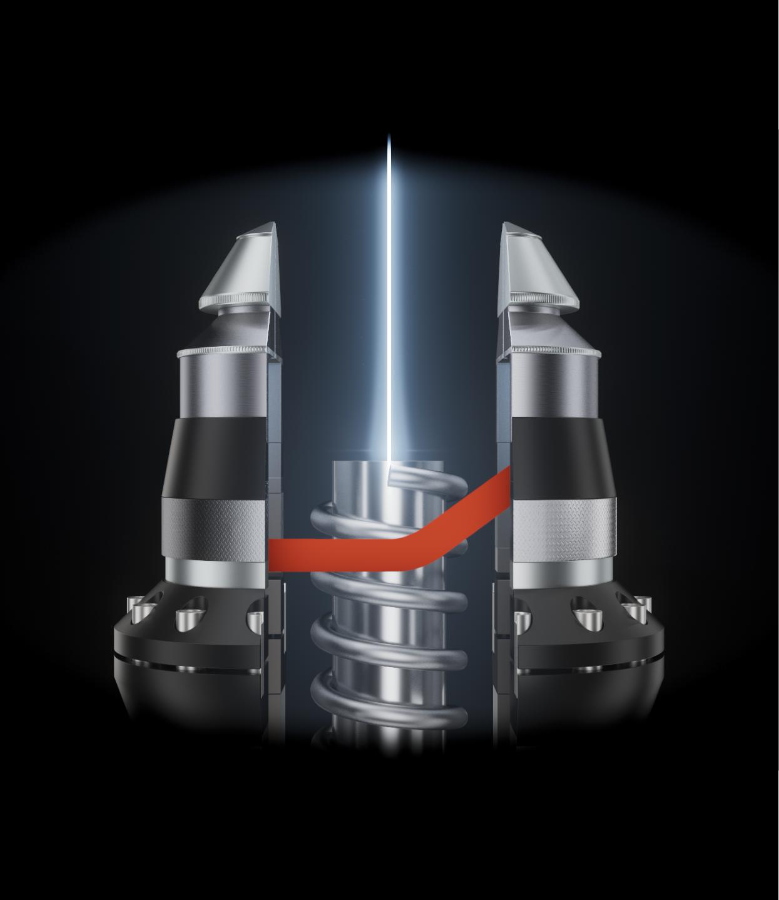

Actuator assembly

Customized production lines for the assembly of actuators and relays. Specific processes or entire production cells can include controlled environment regulation for full quality assurance of the following products:

- RELAYS

- SWITCHES

- CONNECTORS

- CABLES

Inkjet cartridges assembly

Numerous high volume assembly lines delivered over the years for single & multi colour cartridges. IMA AUTOMATION solutions are able to handle all main critical processes:

- FILTER STAKING, SWAGING AND LOADING

- ULTRASONIC/LASER WELDING

- LEAK AND BUBBLE PRESSURE TESTING

- INK DISTRIBUTION