Flyer Winding Technology

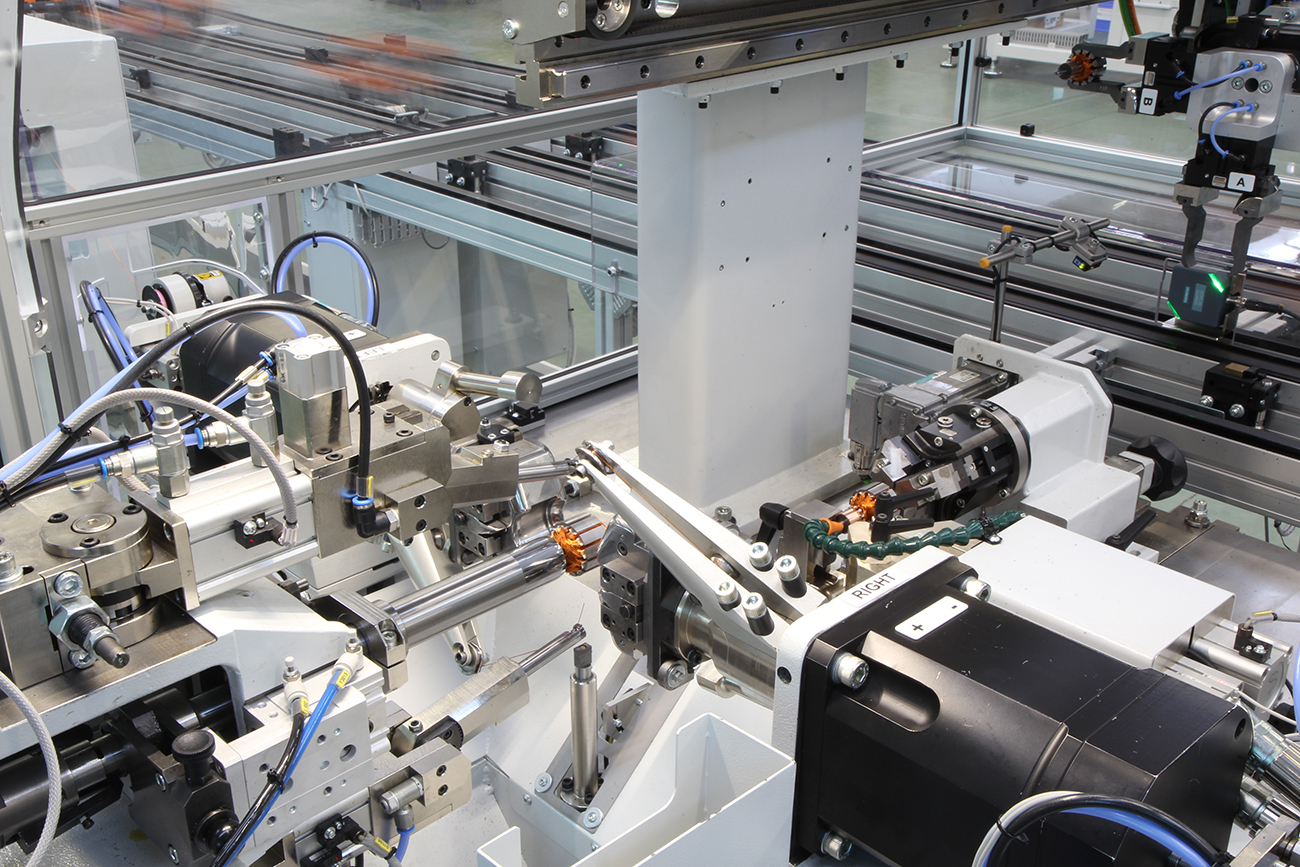

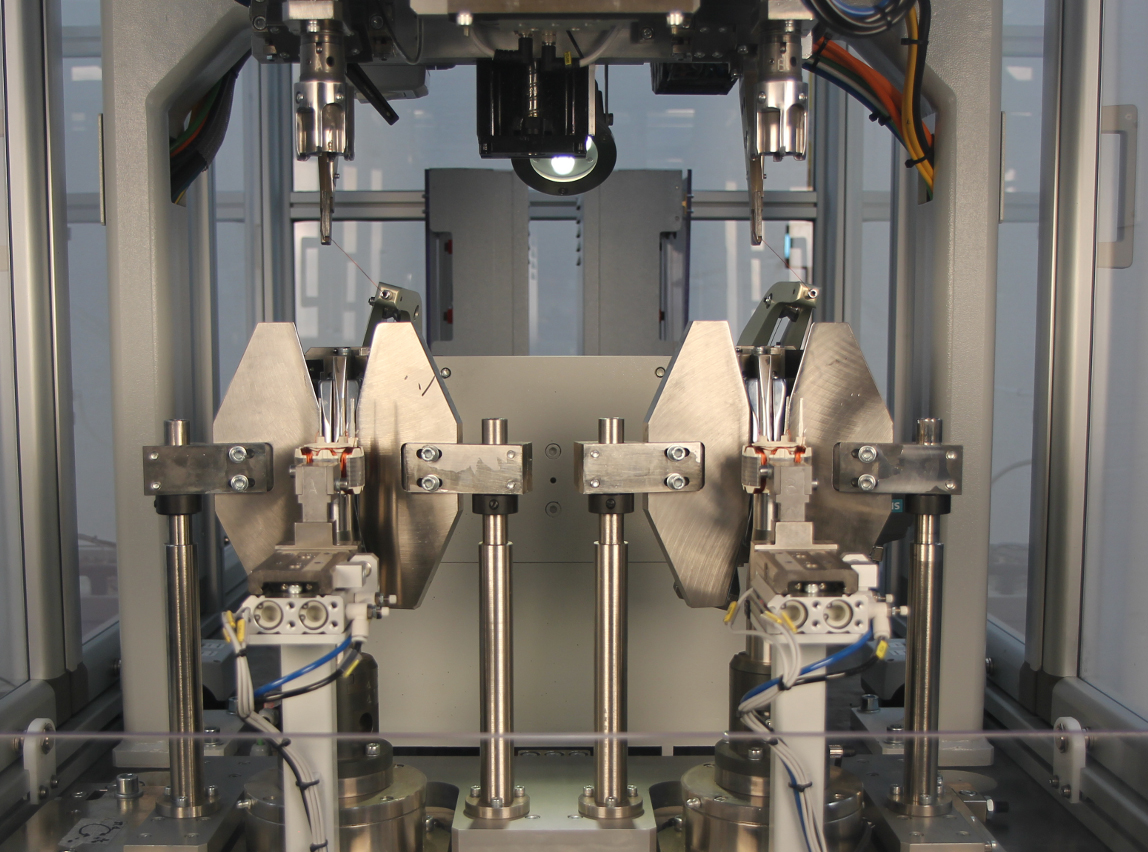

The flyer technology is the starting point of our technological know-how. IMA AUTOMATION designs and manufactures fully programmable wire stratification process with flyer winding technology for high slot fill and accurate coil wire positioning. The high speed winding operations and the multi-station machines, proposed and developed by IMA AUTOMATION, permit to increases productivity and reduces operating space.

With the flyer technology, IMA AUTOMATION, can provide machines and complete line for many stators and rotors:

- SINGLE POLE STATORS

- OUTER SLOT STATORS

- WINDING ROTOR

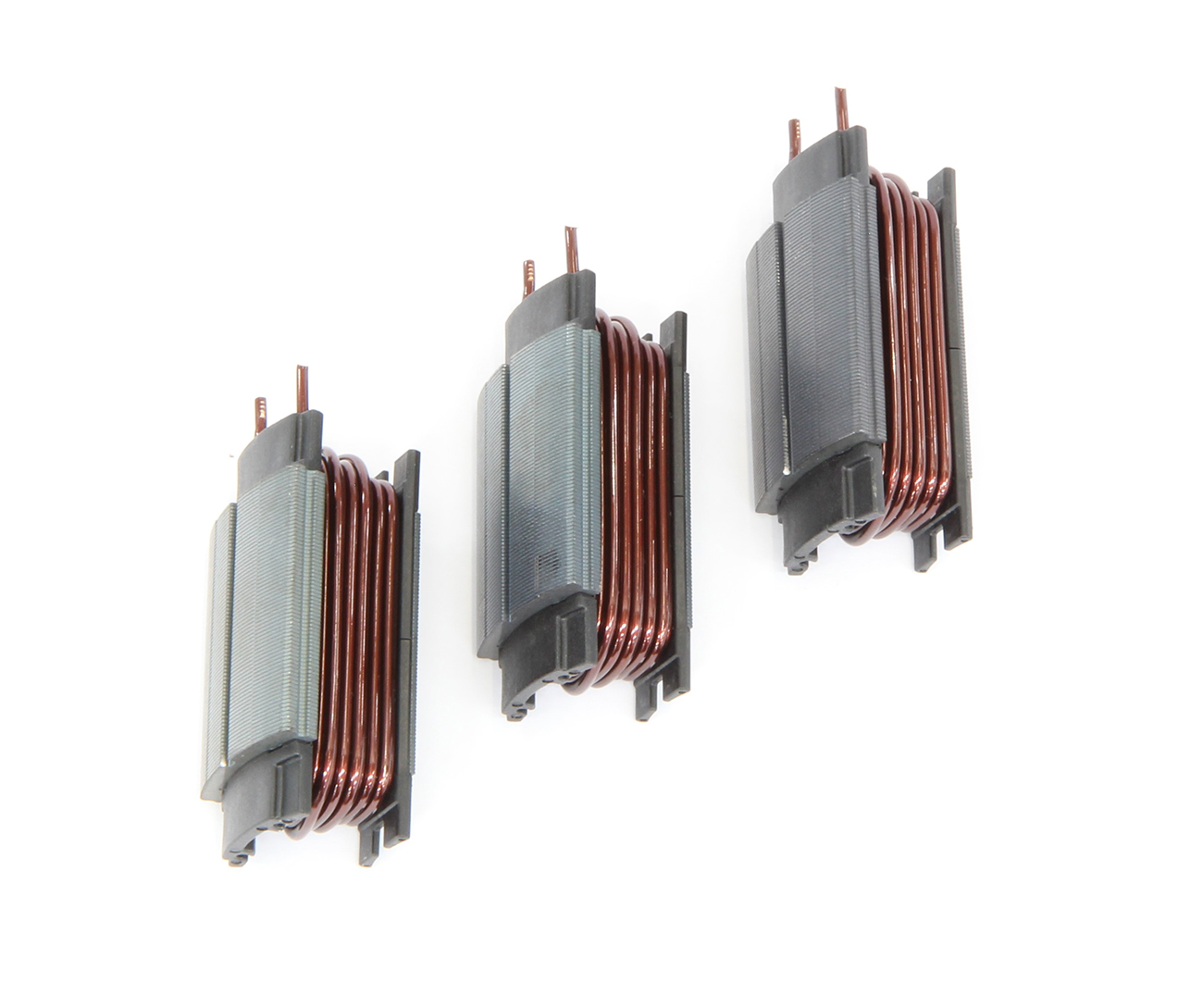

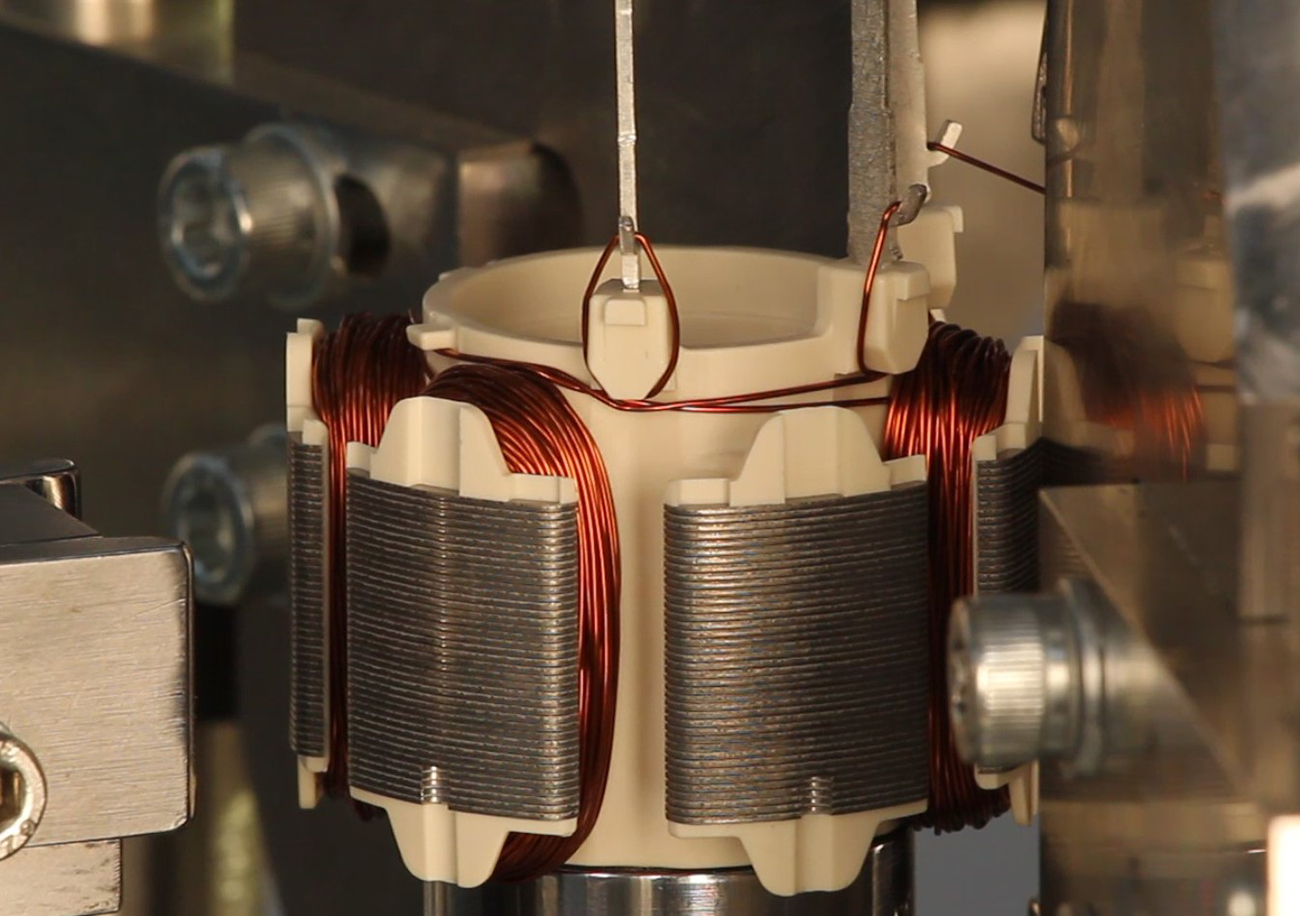

Single pole stator

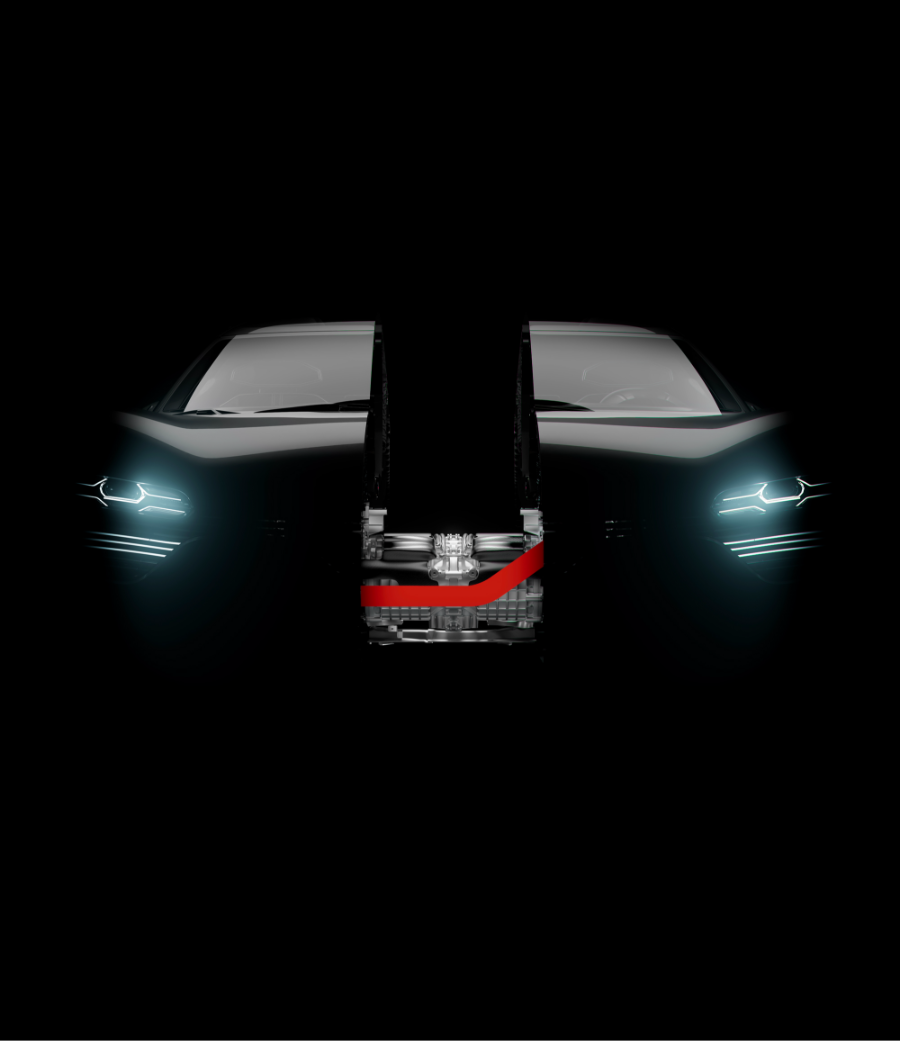

Brushless single pole stators are conceived to meet the growing demand for energy-efficient, compact and best performing motors. The production of such stators requires increasingly complex assembly processes, an excellent know-how and an innovative technology to envelope and welding the poles. IMA AUTOMATION provides full automatic line with exclusive skills and technologies, for key areas of the process, like: single pole assembling, poles laser welding, bus-bar or terminals fusing, hot-drop, and electrical testing.

Outler slot stator

Stator with a particular design based on the external slot geometries for high-speed flyer winding. With an accurate coil wire positioning and a full automatic winding process, IMA AUTOMATION guarantees an excellent control of each phase of the process.

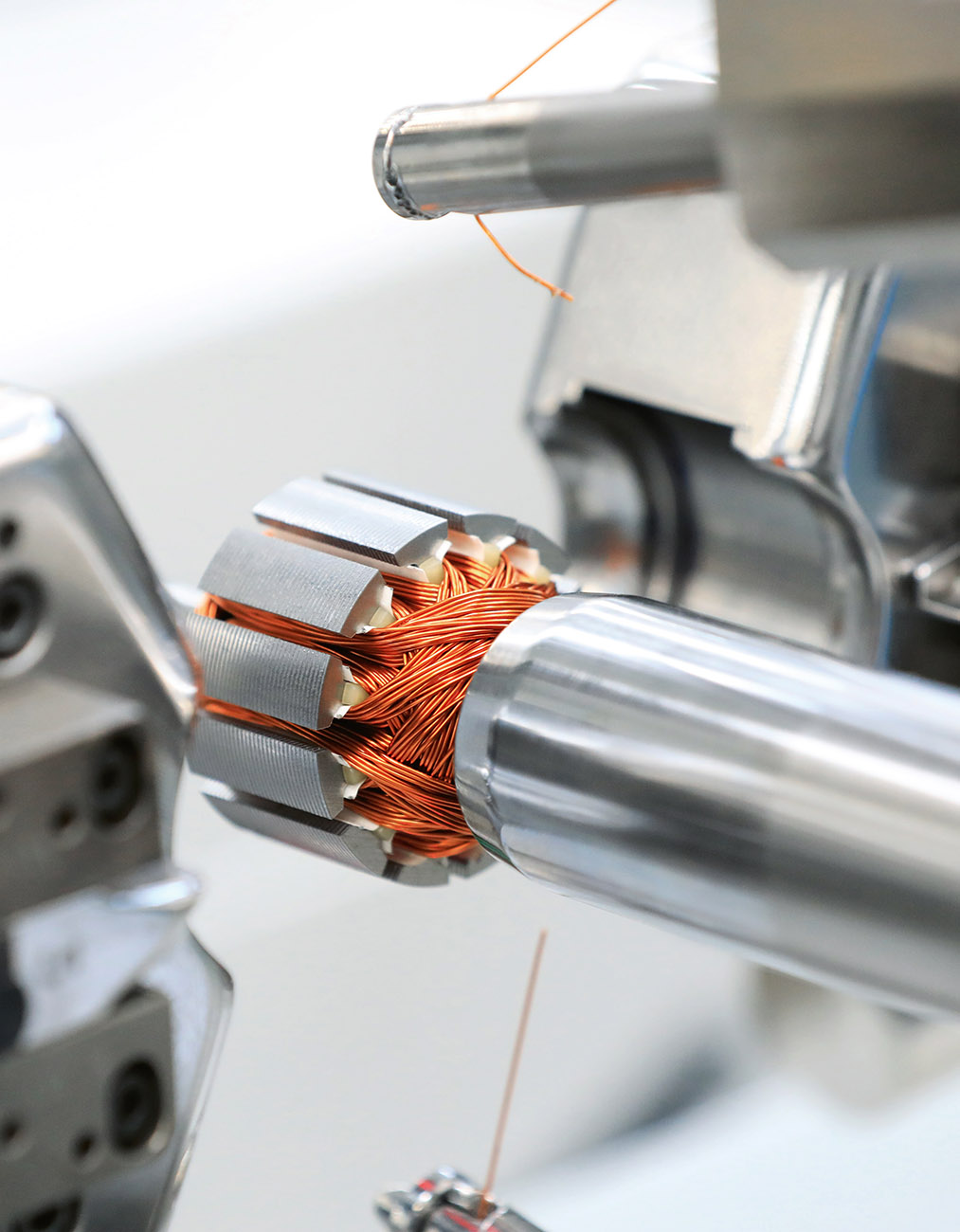

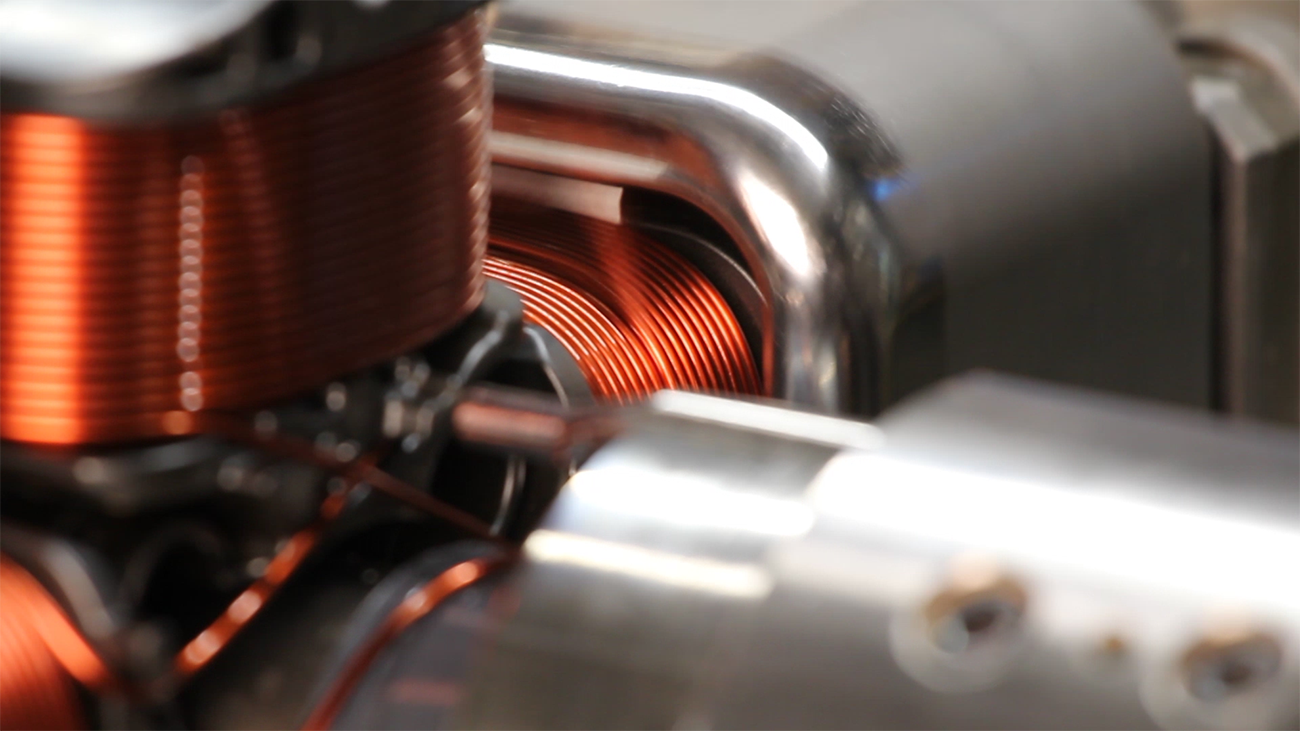

Winding rotor

Rotor winding consists in a programmable wire stratification with flyer winding technology for high slot fill and accurate coil wire positioning. IMA AUTOMATION has the ability and technical know-how to develop machines for the production of many type of products:

- The BLDC Rotor is most suitable for applications that require high reliability, high efficiency, longer lifetime, less noise and more torque per weight.

- Traditional Rotor to elctrify the entire motor system with innovative technology solutions to meet the needs of the production chain as regards precision, productivity, flexibility and reliability.