Surgical Suture Crimping

High flexibility suture crimping solution

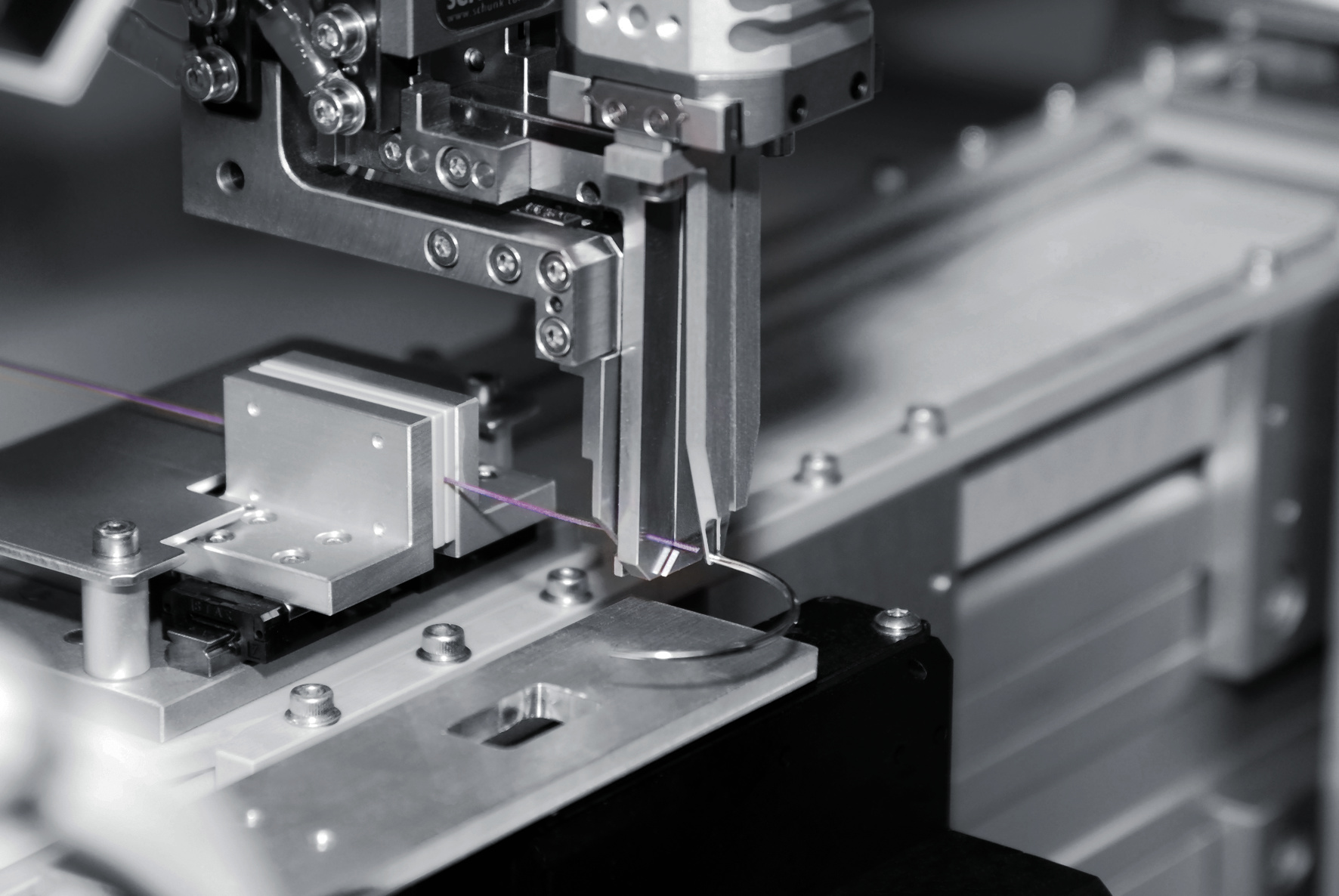

The IMA MED-TECH range of SCM has been specifically designed for the automated assembly and crimping of multivariant surgical sutures.

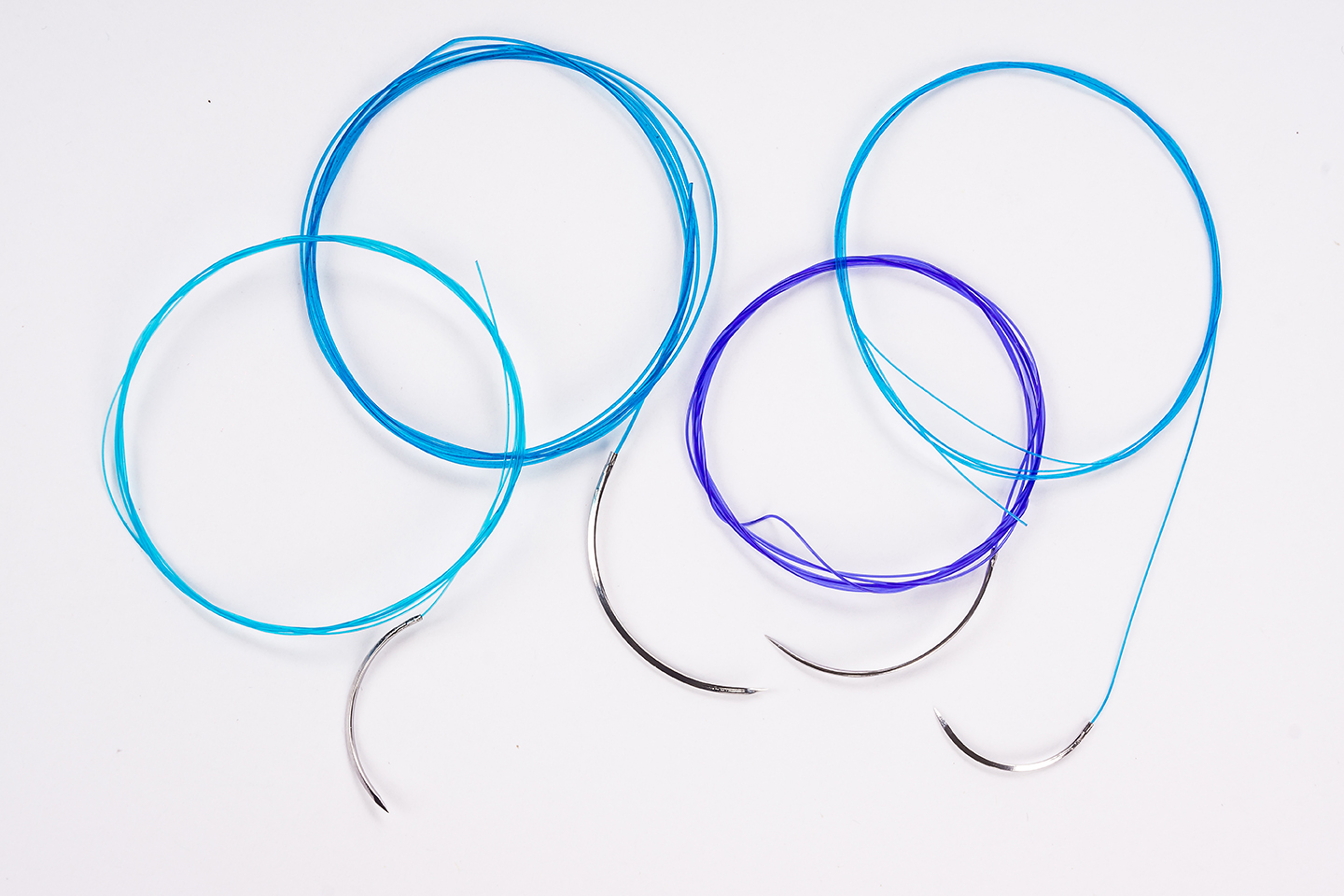

A wide range of needles and threads can be handled and a fast product changeover time provides the flexibility of producing large or small batches.

Well established on the market and with its proven capabilities since its introduction, each suture is subjected to a pull test to guarantee a constant high quality thread needle combination. The finished and tested product is then unloaded into stainless steel receptacles for easy handling.

Advantages of automated suture production

The SCM machines continuously produces a stable quality of sutures from start to finish and reliably guarantee a cost effective production in multishifts of up to 24/7. During the machine operation, the needles can be loaded in bulk and the finished product unloaded without interruption. A machine standstill is required only to change the thread spool or the product variant.

Despite the high degree of automation, the machines are very flexible and suitable for almost all common surgical sutures. This core advantage of the SCM leads to a minimum downtime and a maximum efficiency in production.

Main key processes

Main key processes for various needle geometries, thread qualities and thread sizes. Process sequence depending on the machine model.

- THREAD LOADING & STIFFENING

- THREAD CUTTING

- NEEDLE LOADING AND ASSEMBLY ON THE THREAD

- CRIMPING ON THE THREAD INTO THE NEEDLE

- PULL TEST FOR QUALITY CHECK

- PRODUCT UNLOADING