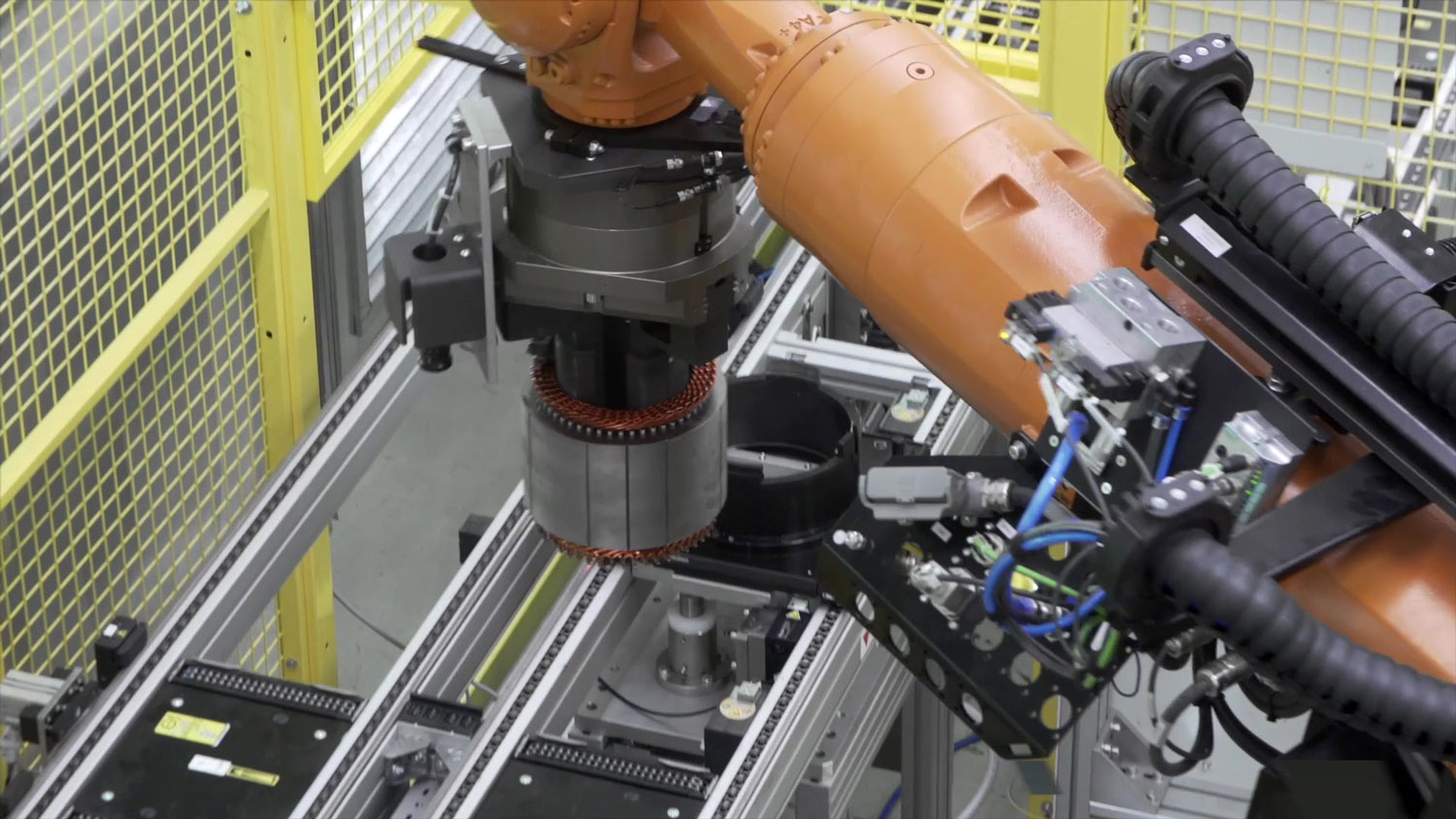

Robotized Handling Solutions

Tailor-made robotized handling systems

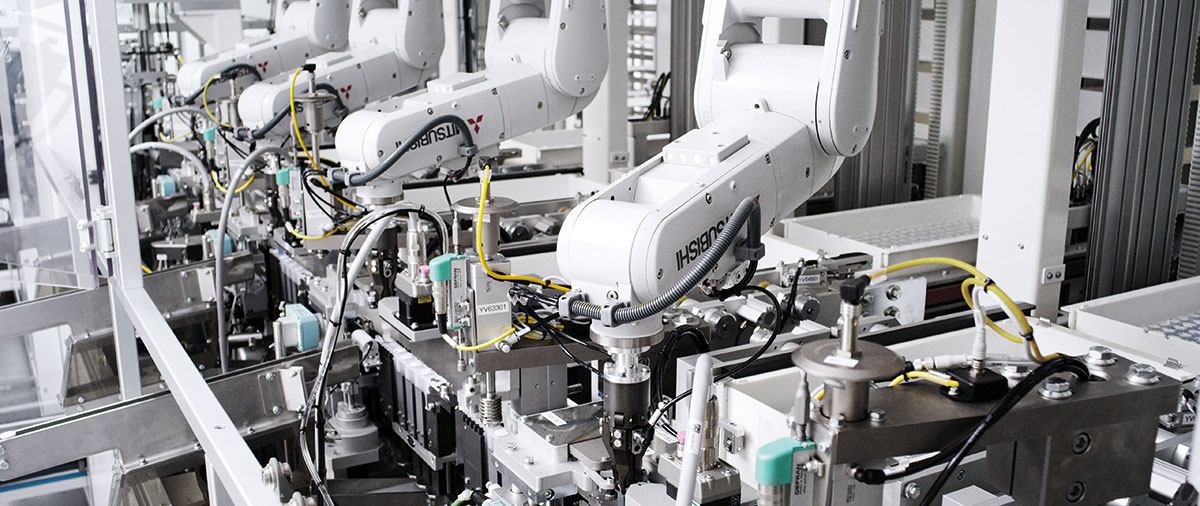

The strong synergy with primary I.M.M. and Mold Makers and IMA Automation skill in developing control software enable us to develop robots perfectly integrated into the process and to achieve top class performance.

Handling systems (units or productive integrated cells) integrating standard robot available on the market and duly customized to perform the requested operations.

- ROBOTIZED UNLOADING SYSTEMS

- SINGLE AND MULTIPLE IN LINE DEMOLDING

- INTEGRATED ASSEMBLY

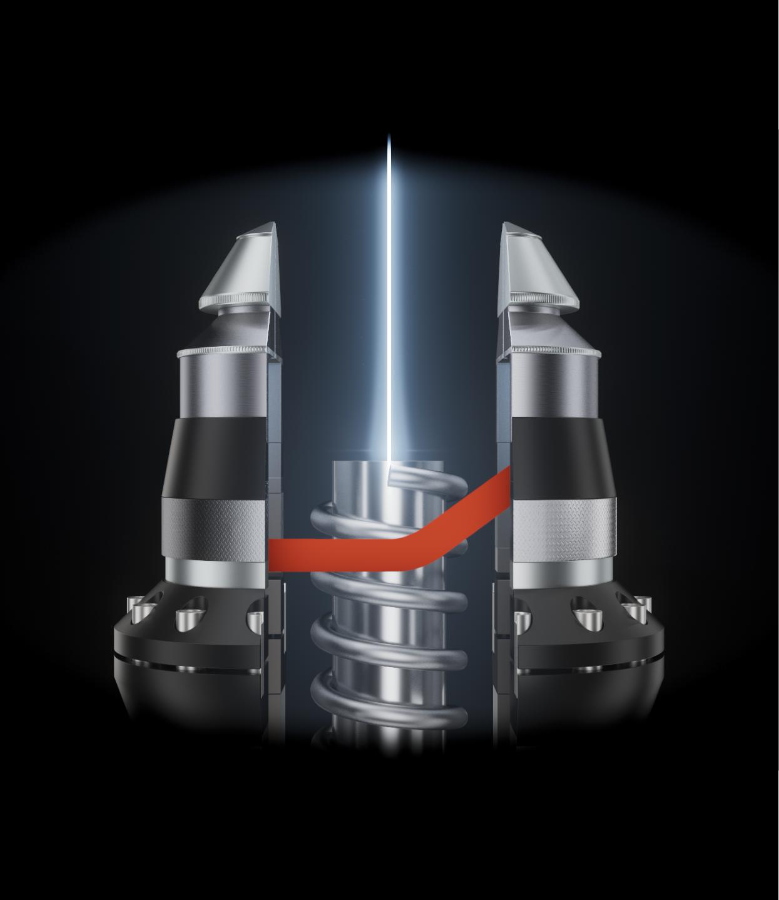

- DELTA SCARA ANTROPOMORPHOUS ROBOT INTEGRATION

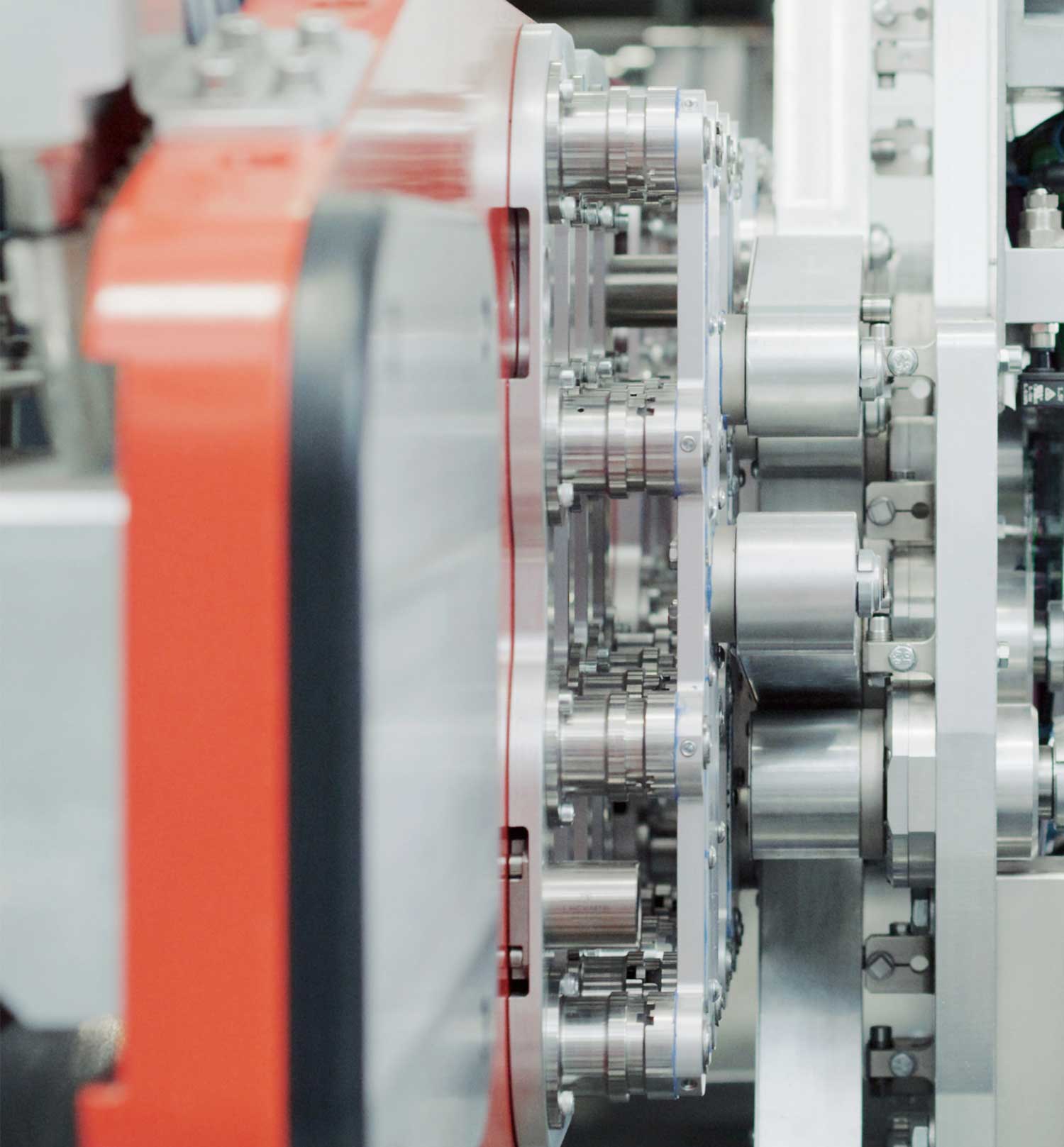

In-line demolding

IMA AUTOMATION can count on twenty years experience gained in demolding and assembly applications. Our skill in the use of lightweight and composite materials enables us to offer side entry robots with state of the art speed and precision performance in the picking up of components, even with high cavitation molds (48 96 cavities).

- Speed 8 m/s Acceleration up to 80 m/s2 Total Demolding time down to 0.25 sec Up to 96 cavities

- Integration with High Tons I.M.M. Stack mold multicomponent demolding Pre orientation systems Unloading counter arms.

Customised integrated robotized cells

IMA AUTOMATION offers customised production cells complete with robot solutions that integrate assembly , inspection and packaging operations. Highly technological platforms and innovative technical solutions both for in line assembly of several components and for the handling of individual products that require additional operations, like folding, welding, inspection, printing and packing.