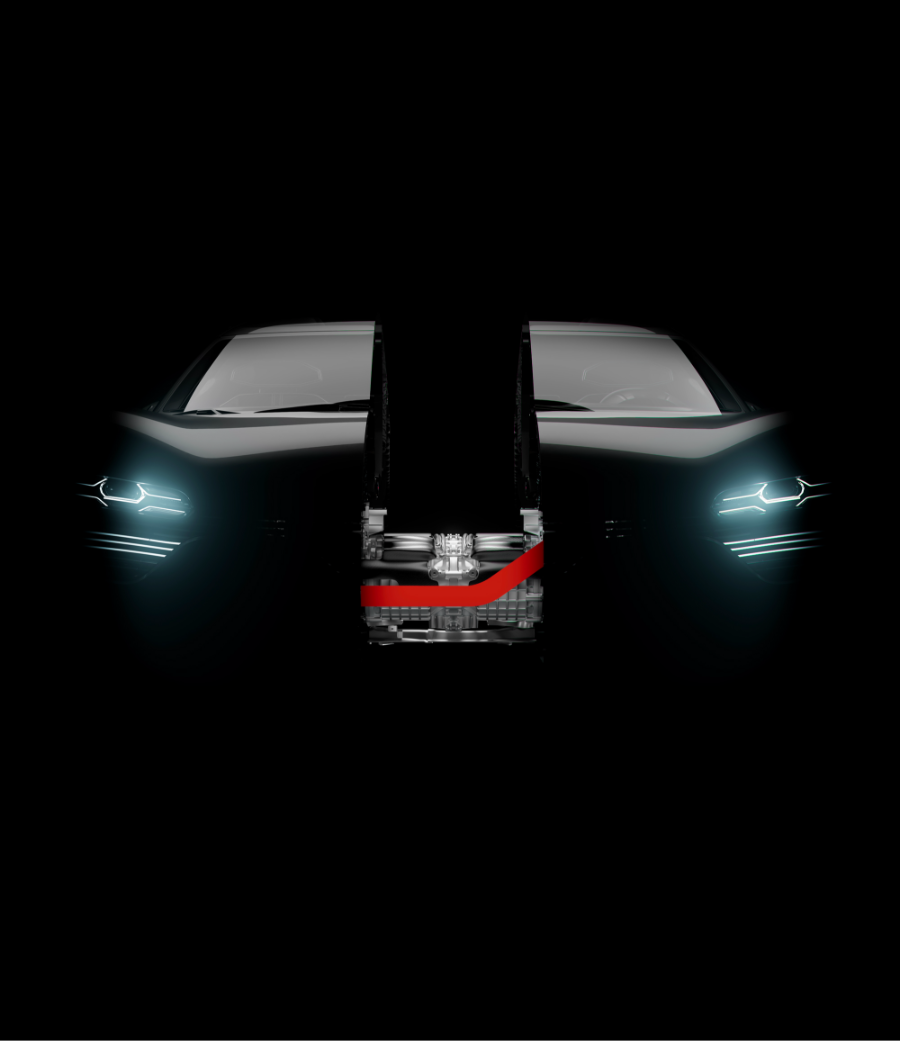

Hairpin Technology

The introduction of traction electric motors manufactured with hairpin technology encouraged IMA AUTOMATION to invest in a research and development program for automatic machines to produce these types of motors. With a consolidated know-how in manufacturing special machines we ensure high speed and accurate hairpin design to manufacture hybrid stators.

Forming and inserting technology

Slot insulation technology

With 40+ years of strong background experience in universal motor applications, in this process the machine unwinds, folds, cuts, and inserts insulating paper into stator stack slots. Paper portions are placed one by one through coordinated translation and indexing. Each insertion is verified for position and jams. Various insulation shapes ensure a perfect fit, providing stability and pull force without requiring a calf.

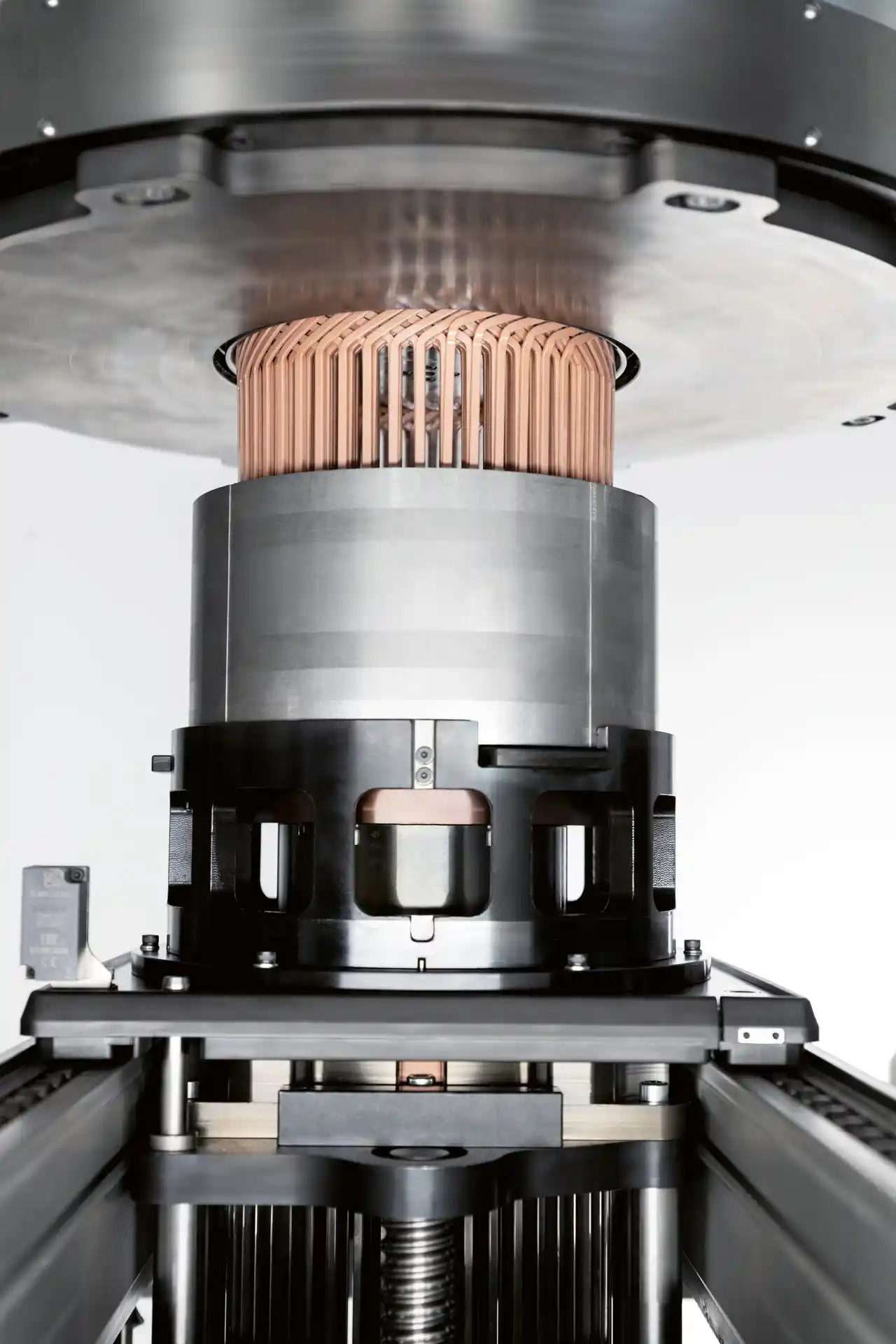

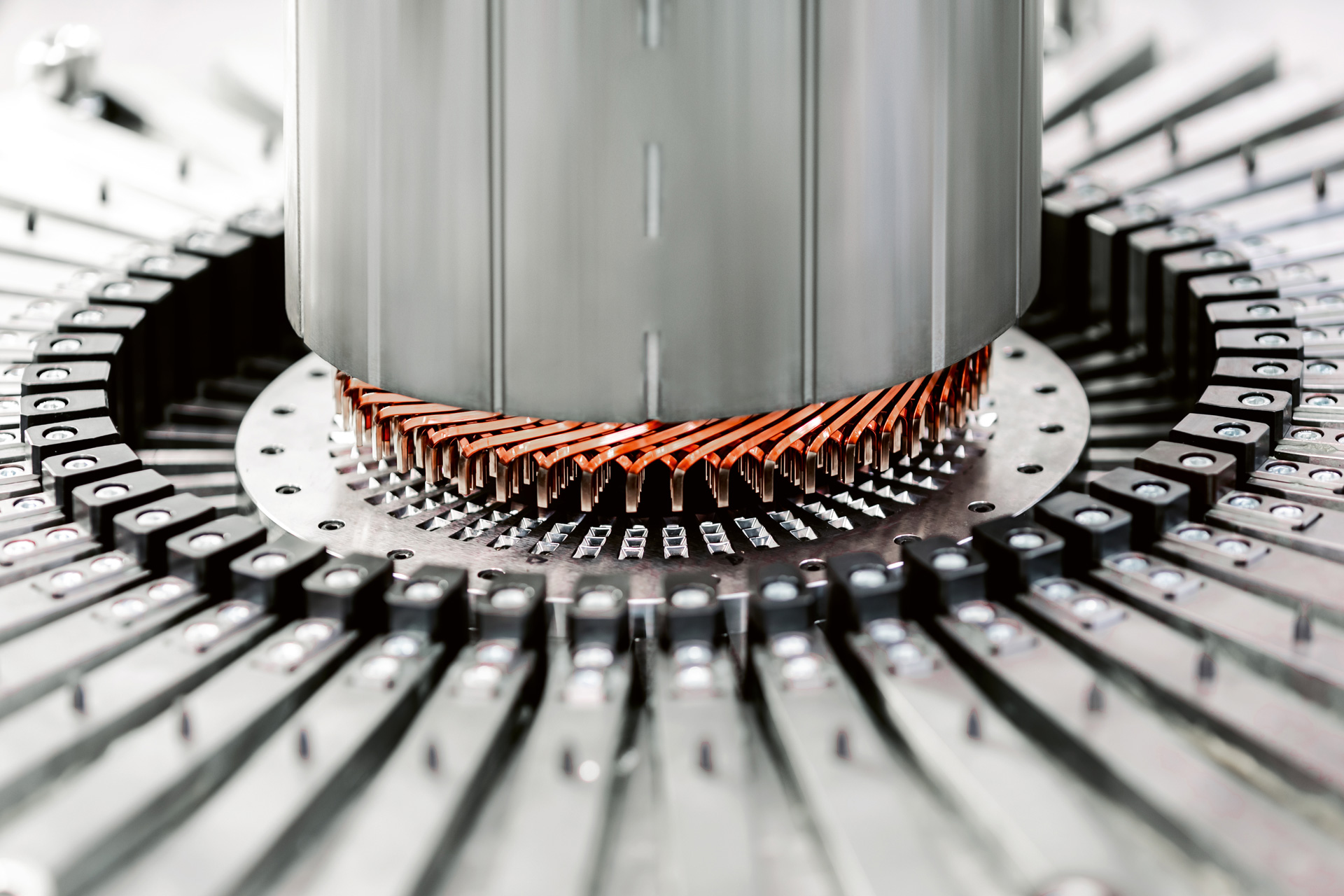

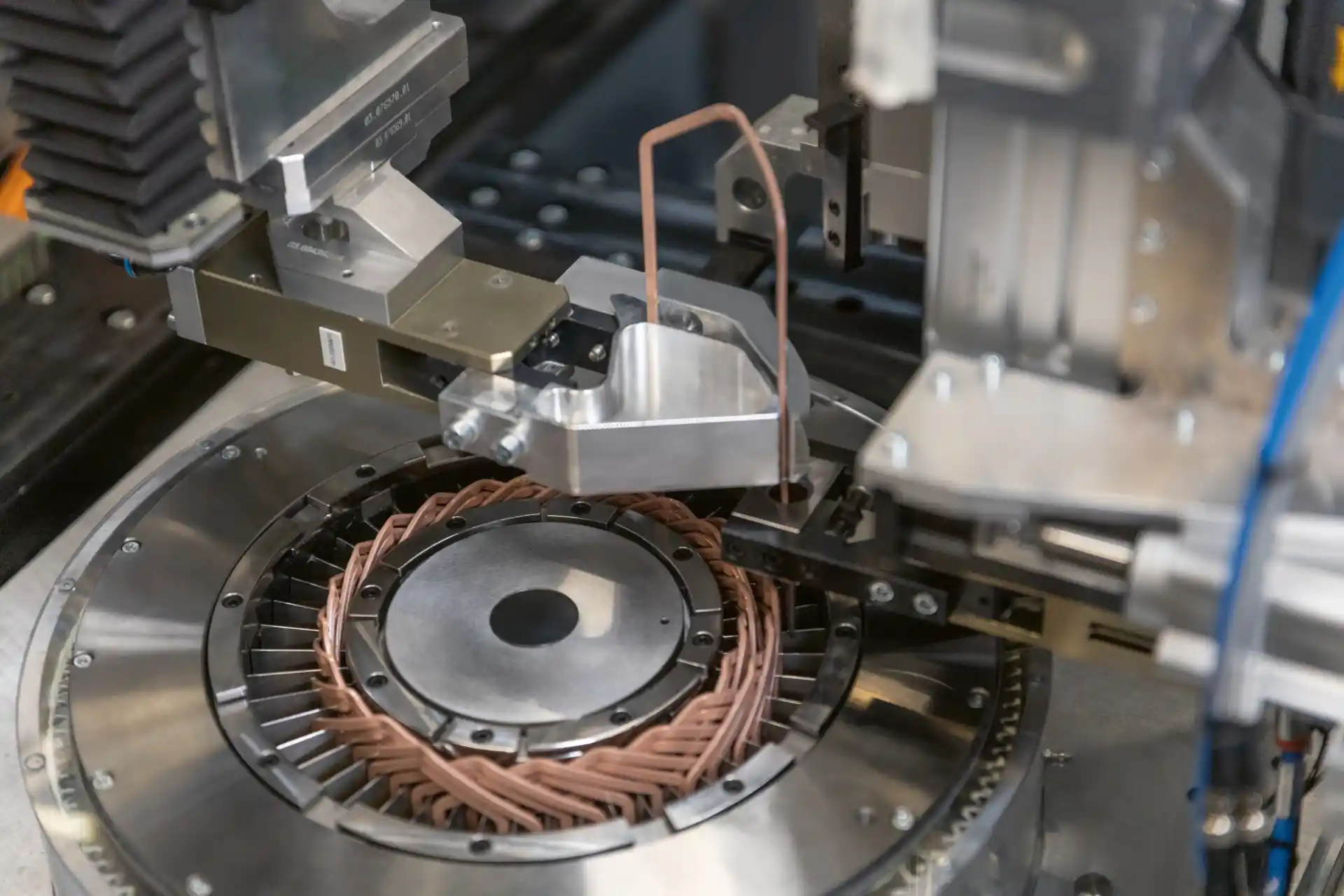

Hairpin Forming and Inserting Technology

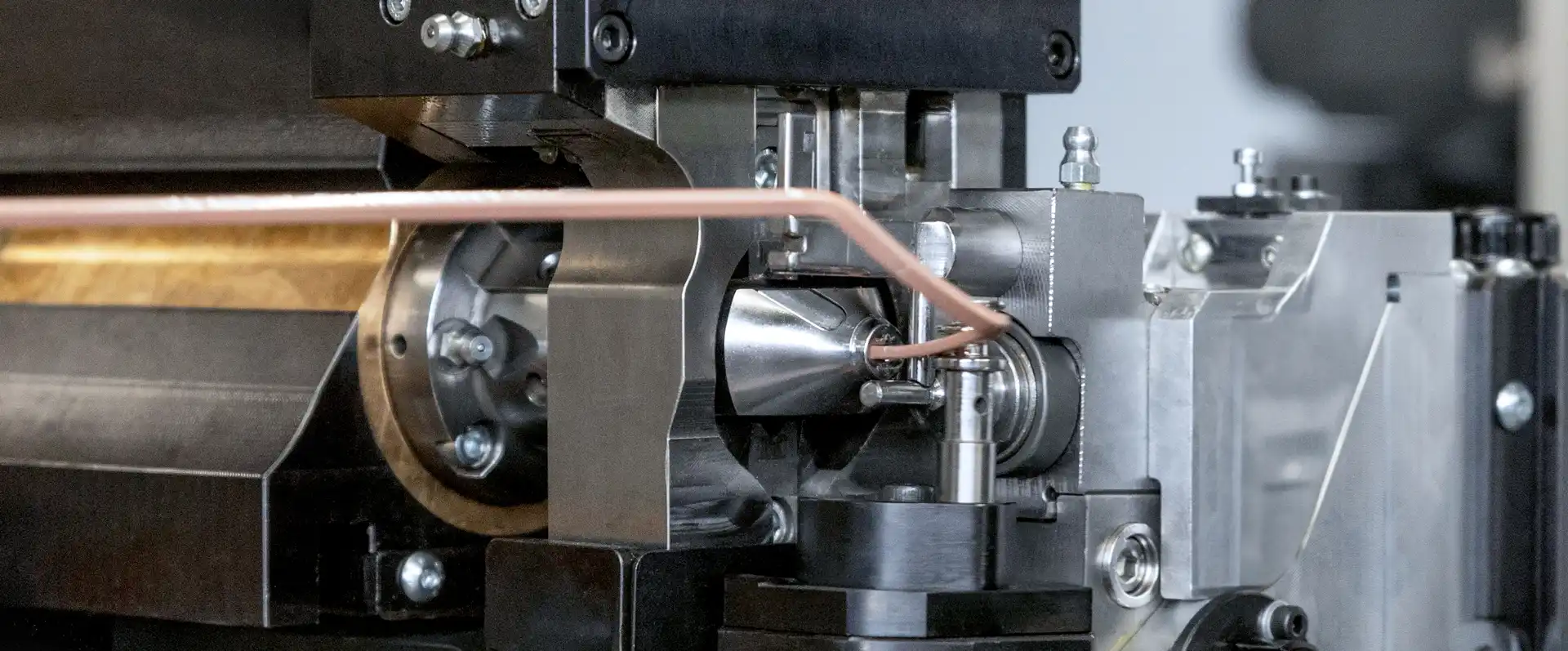

With a strong know-how in reels manipulation, IMA AUTOMATION offers hairpin forming machine with conductor feeding system, laser wire decoating, single hairpin creating and inserting stations.

This technology permits to perform all hairpin, pitches, lengths, product specification, through integrated wire unrolling and laser peeling in 'ON FLY’ mode, ensuring seamless forming. A 6-axis NC-controlled robot enables easy shape changes via HMI parameters. Prepared hairpins are assembled in single/multi-layer nests, transferred to insertion stations via a shuttle and portal system.

Stator assembly

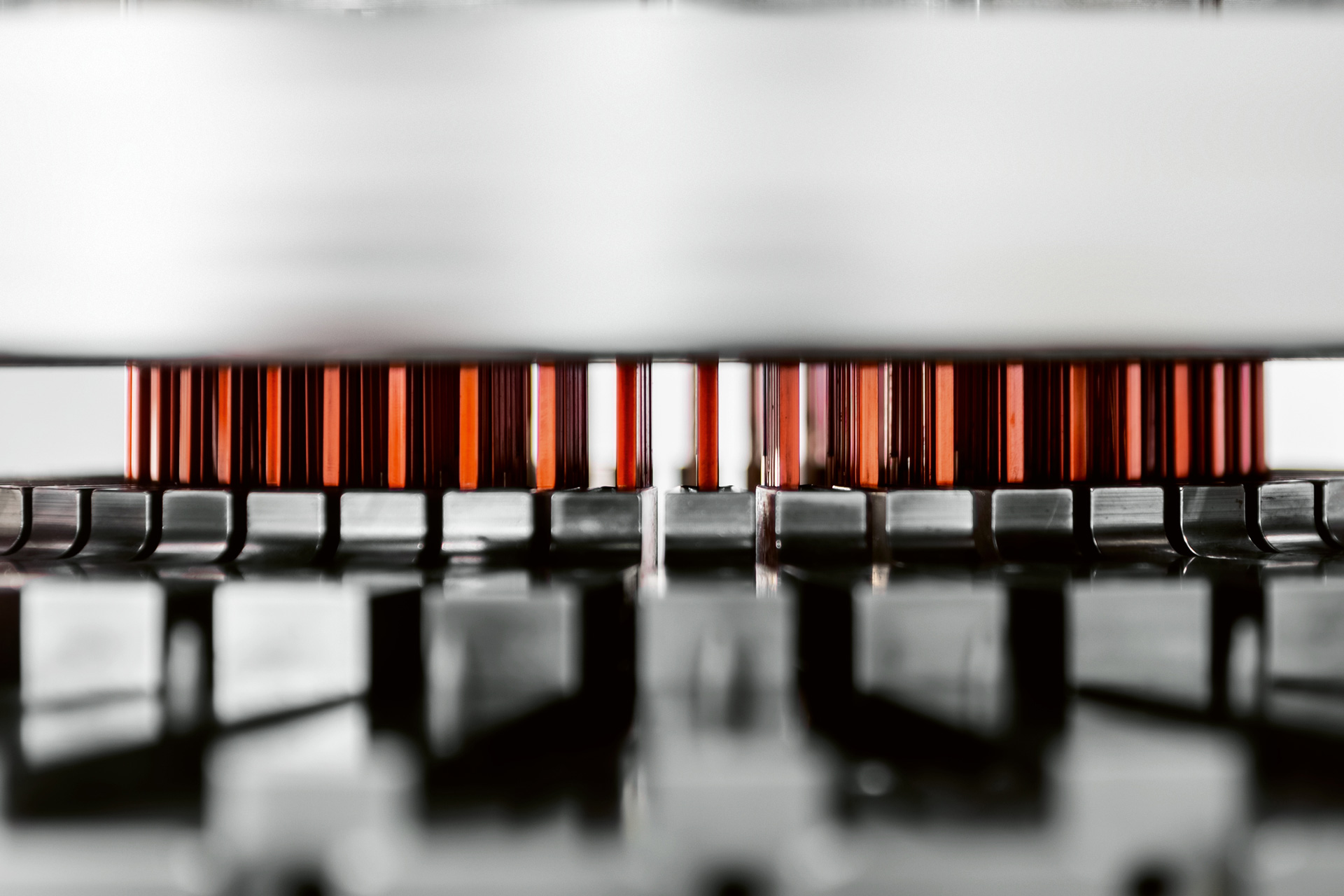

Widening & Twisting Technology

IMA AUTOMATION has developed a highly flexible NC-controlled technology to meet customer needs. The process unit integrates three key steps: loading, widening, and twisting.Widening is performed based on the stator slot count, while twisting is managed by an 8-axis NC-controlled system that bends each conductor layer independently.

Wire cutting solutions

IMA AUTOMATION presents different solutions for the wire cutting operation:

Laser welding technology

Welding is crucial in hairpin technology and a core expertise of IMA AUTOMATION. It uses laser beam deflection with motorized mirrors on multi-axis devices. The system includes a laser generator, coaxial fiber, PFO head, and an optical tracking system with an integrated camera for precise target detection. Independent units grip and hold each conductor pair for perfect alignment.

Electrical testing

IMA AUTOMATION has many years of experience on machine testing. In all the steps, we developed technologies installed on each machines offering to the customer the best solutions in terms of instruments, hardware and software.

Standard tests are always present on IMA AUTOMATION instruments:

- Hi-pot test up to 3500 V at 30 mA

- Surge test up to 6000 V

- RL test for resistance and field measurement

- Hi-current test up to 200 A

- Insulation resistance up to 200 MΩ

- Partial discharge - surge test/high-voltage measurements

Other processes integration

Automatic and flexible process solutions based on customer request are integrated with robot and 3D vision systems for the stator inspection and final control.

- Quality control

- Manual operations

- Visual inspection