IMA Digital

Make it real

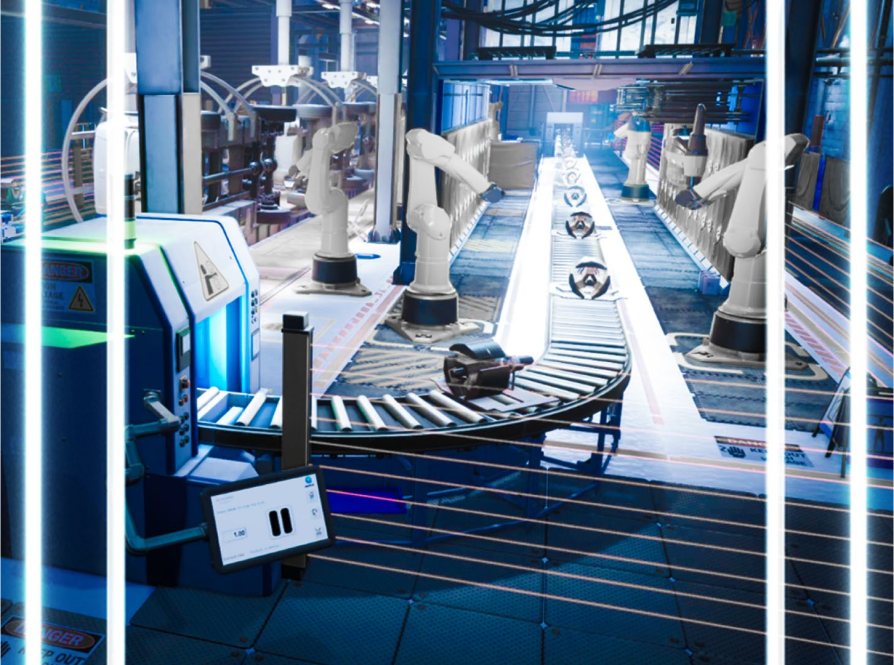

The IMA Digital project is a strategic initiative by the IMA Group to integrate advanced digital technologies into production processes, enhancing efficiency, quality, and control. Within IMA AUTOMATION, the division specializing in automatic assembly of industrial components, this initiative translates into customized solutions for high-precision assembly applications.

Make it real

The IMA Digital project is a strategic initiative by the IMA Group to integrate advanced digital technologies into production processes, enhancing efficiency, quality, and control. Within IMA AUTOMATION, the division specializing in automatic assembly of industrial components, this initiative translates into customized solutions for high-precision assembly applications.

AI-Driven solutions

IMA Automation integrates connected machines with traditional and generative artificial intelligence, delivering solutions that enhance clients' production efficiency. AI processes real-time data to optimize maintenance and boost performance, while generative capabilities explore innovative scenarios. Continuous support ensures smarter and more resilient industrial processes.

Continuous monitoring solutions

IMA Automation offers cutting-edge monitoring solutions: IMA Sentinel, a smart system ensuring real-time machine performance tracking, and IMA Control Room, a centralized hub for remote supervision, diagnostics, and data analysis. Together, they optimize productivity, reduce downtime, and enhance operational efficiency.

Digital Twins and Virtualisation solutions

IMA Automation leverages digital twins, line simulations, and plant virtualization to optimize production processes, enabling precise forecasts and pre-implementation testing. The integration of the industrial metaverse introduces immersive environments for remote management and training, ensuring efficiency and innovation in industrial operations.

Digital solutions for After-Sales Support

IMA Automation offers advanced H247 support enhanced by remote monitoring, ensuring real-time issue detection and resolution. Digital training tools enable clients to upskill teams efficiently, while troubleshooting applications and a streamlined ticketing system simplify problem management and ensure timely interventions. These solutions guarantee seamless post-sales support and maximized operational uptime.

Our Digital Vision

Recently, we published our Digital Manifesto to highlight the pivotal role of IMA Automation in driving the adoption of cutting-edge technologies. This vision embodies our commitment to innovation, efficiency, and sustainability, paving the way for a smarter and more connected industrial future.