E-Motors

Innovative Winding Solutions

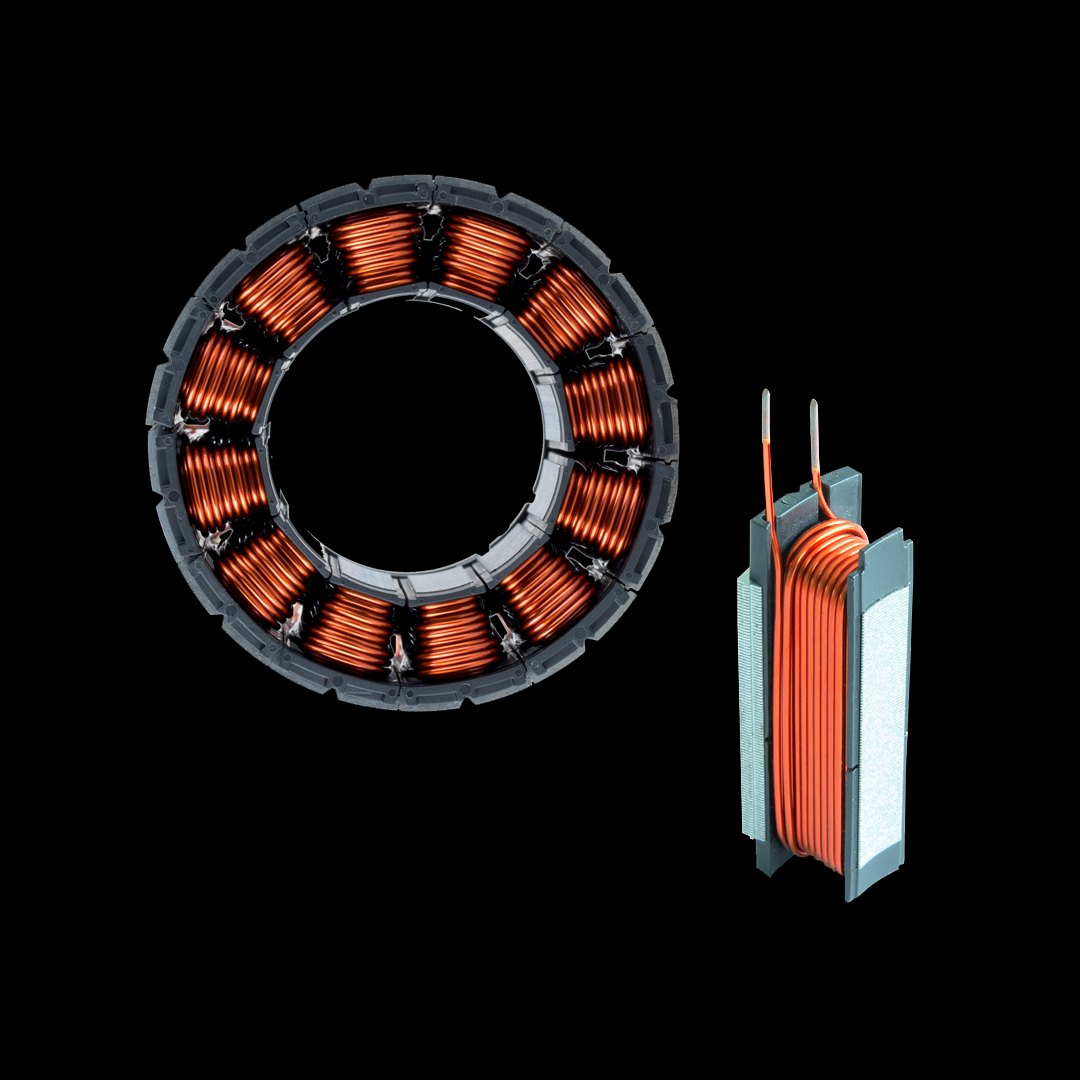

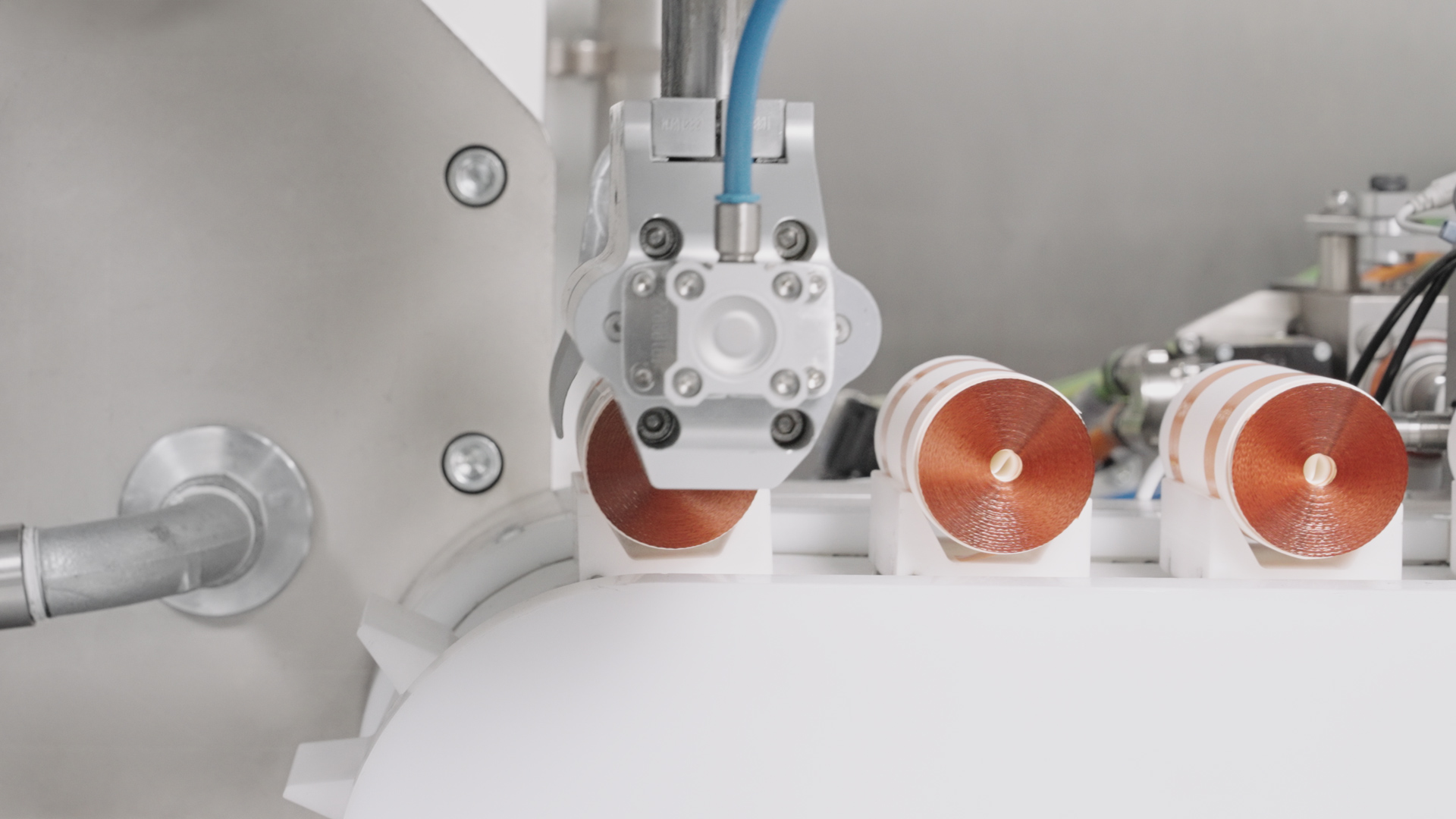

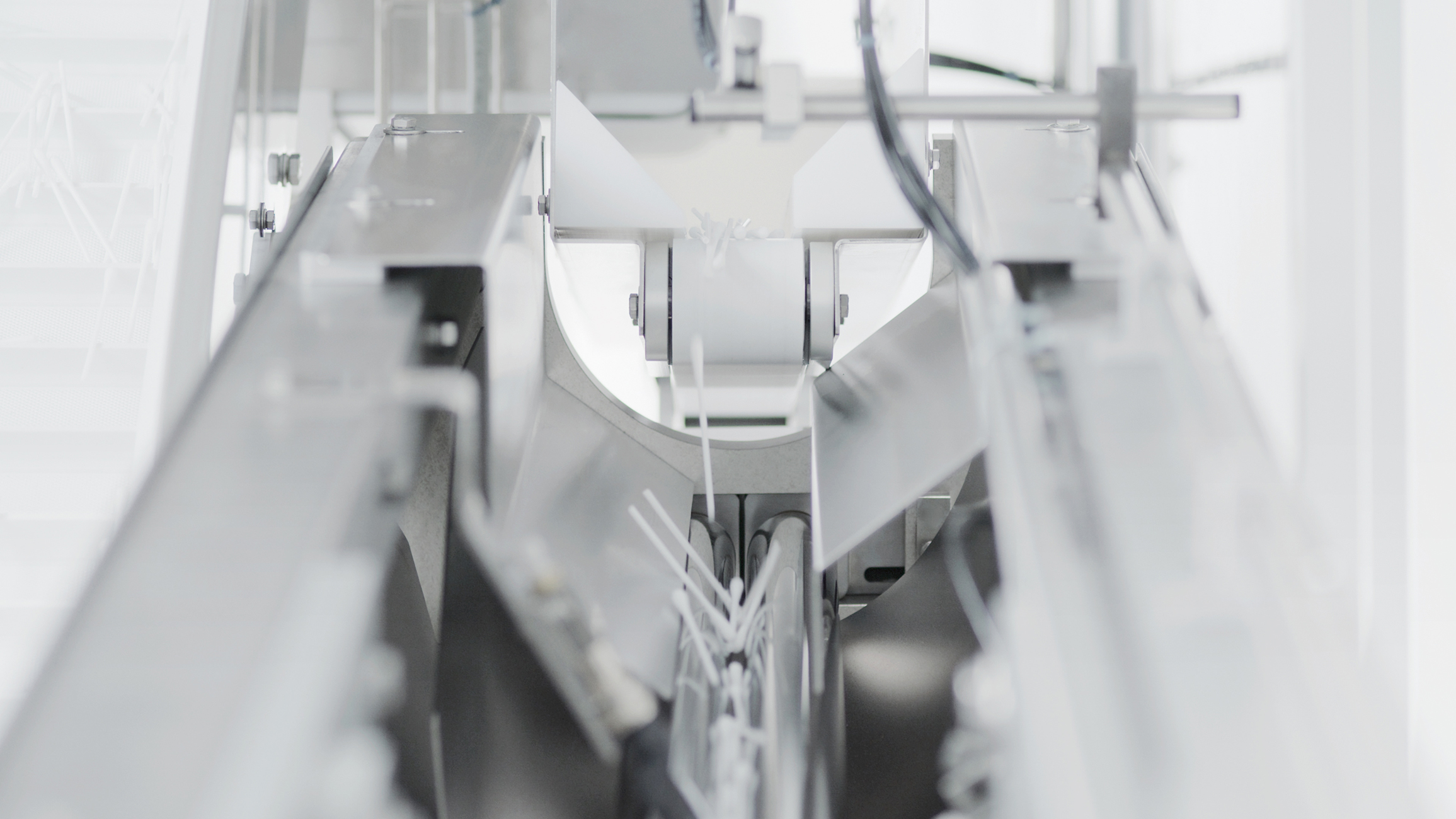

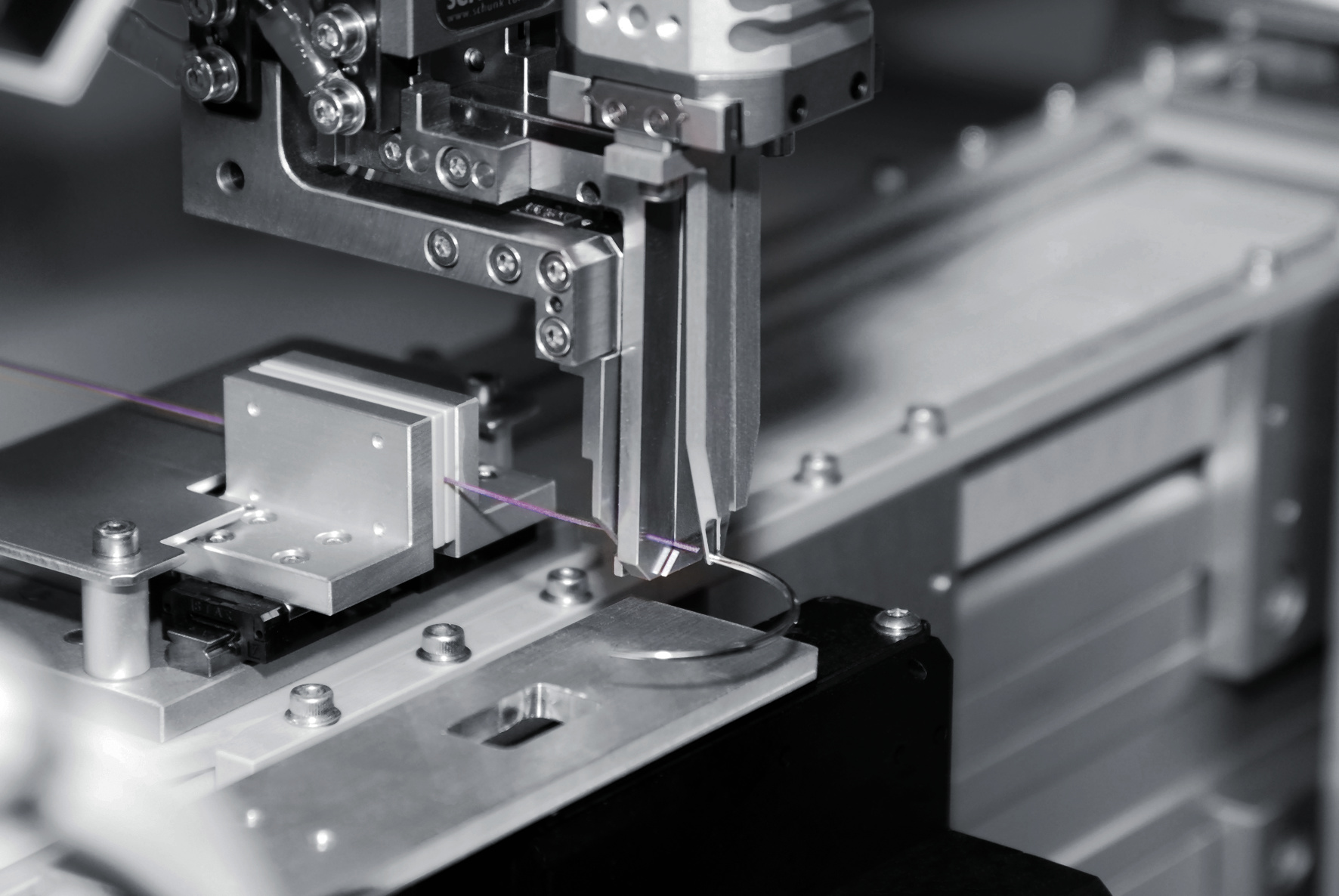

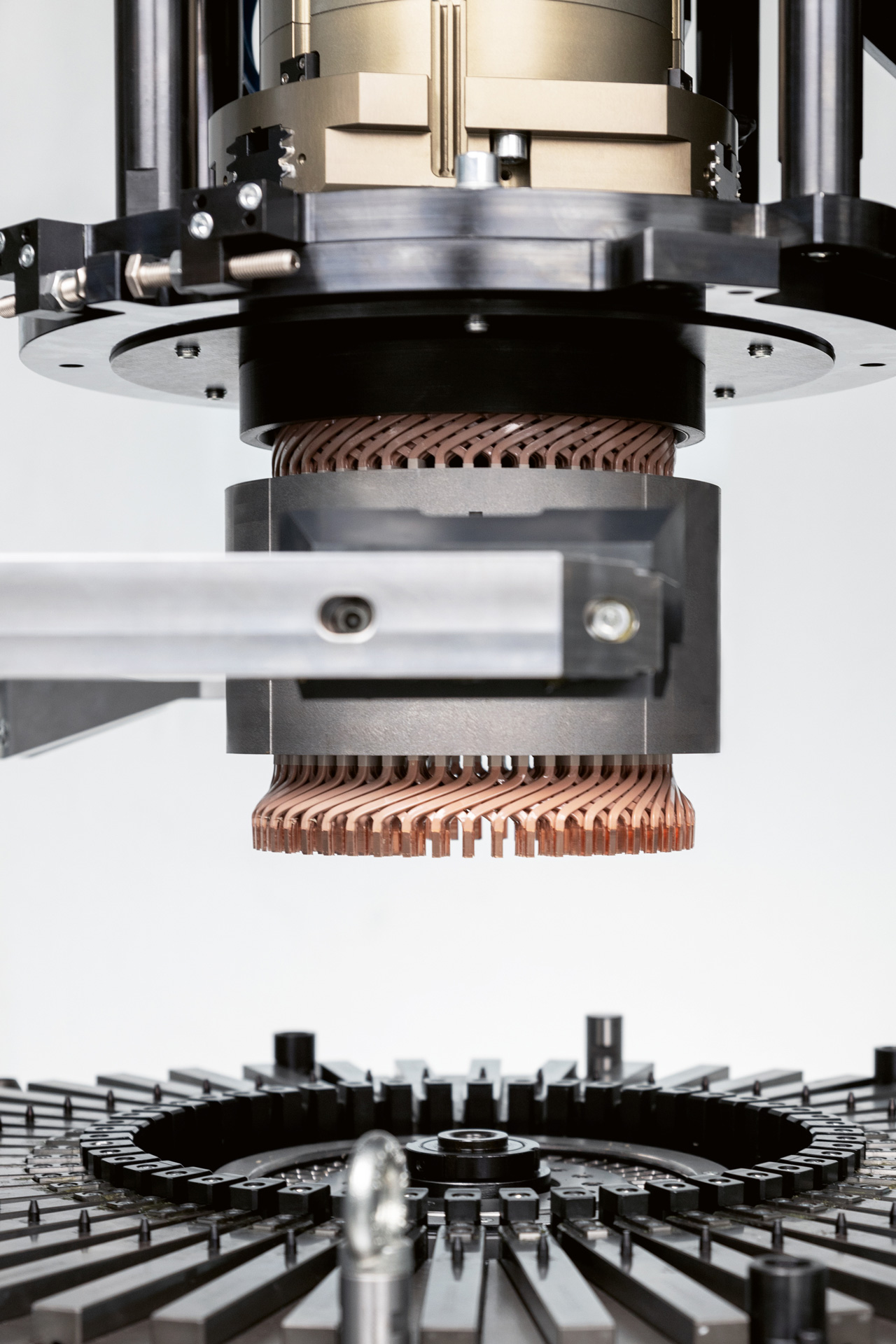

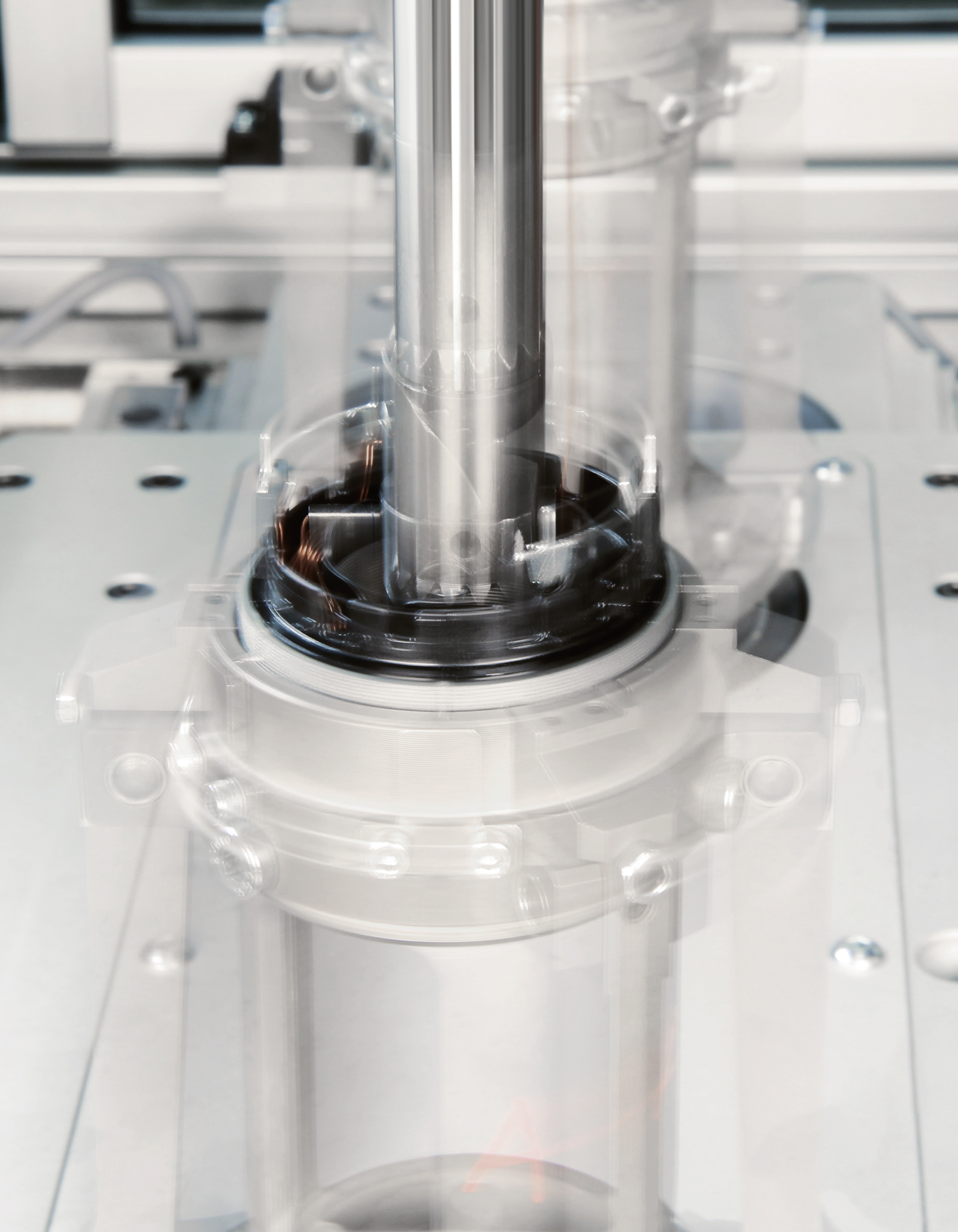

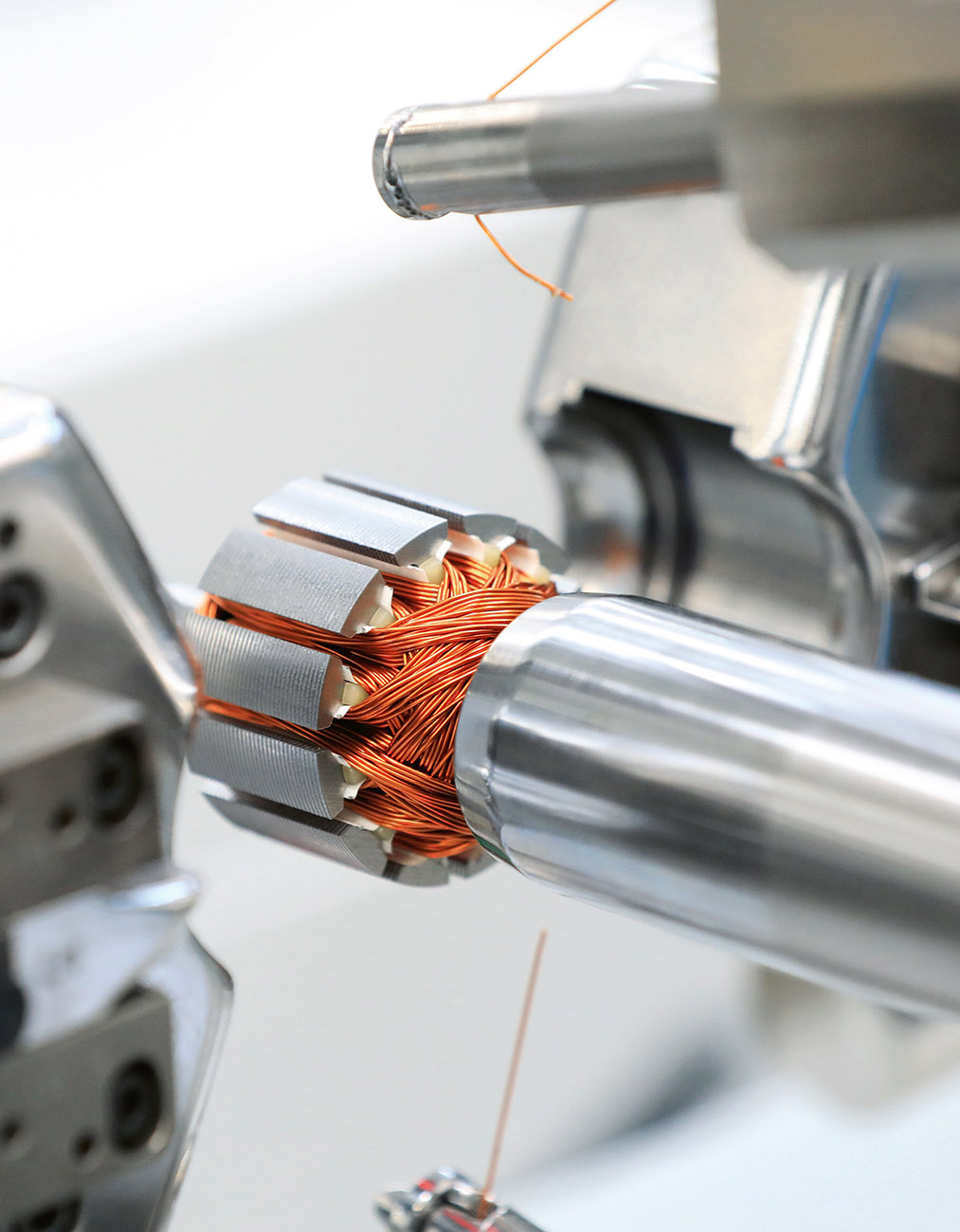

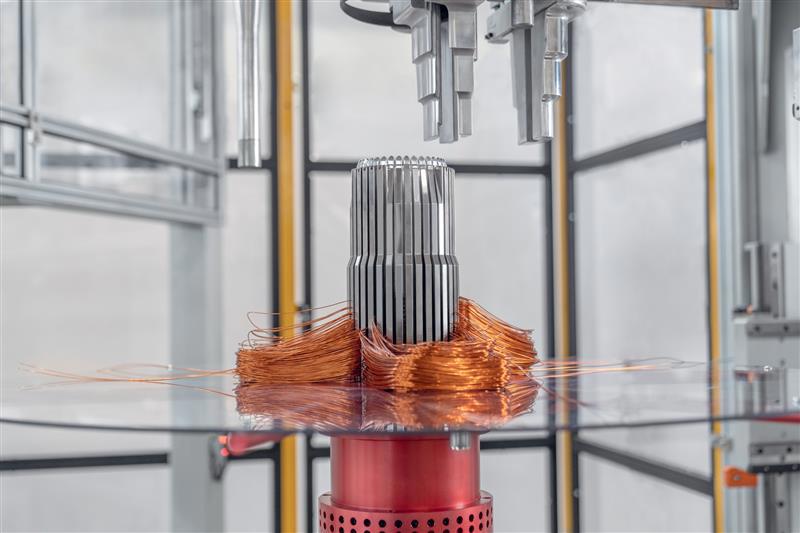

Universal and brushless motors are the first electric motors where IMA AUTOMATION has created technological know-how. From the beginning we accomplished tailored and innovative solutions to meet all quality and production requirements. We ensure dynamic production, high flexibility and elevated performance in coil winding processes.

Innovative Winding Solutions

Universal and brushless motors are the first electric motors where IMA AUTOMATION has created technological know-how. From the beginning we accomplished tailored and innovative solutions to meet all quality and production requirements. We ensure dynamic production, high flexibility and elevated performance in coil winding processes.

Industrial Applications

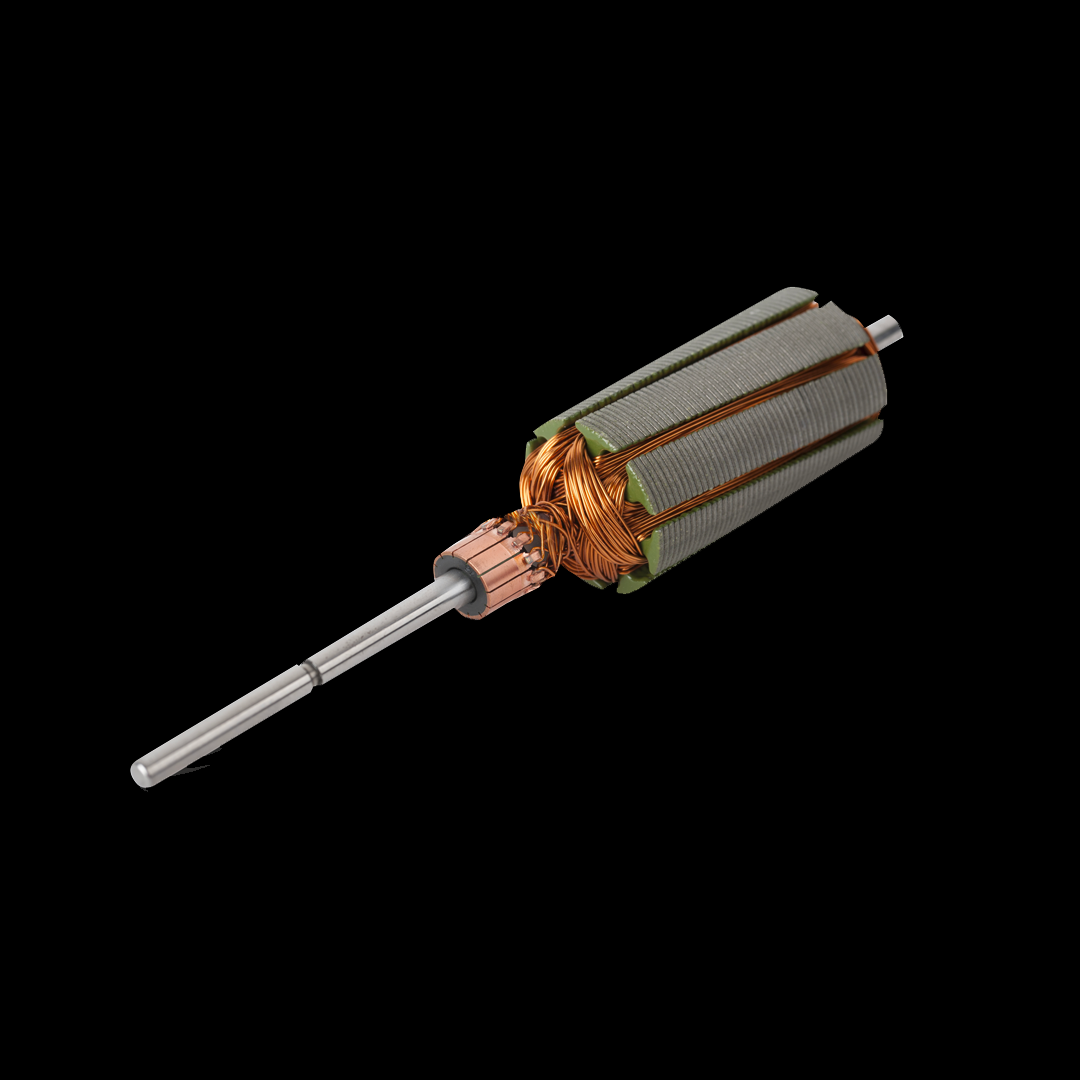

Electrical motors for industrial applications are designed to guarantee high reliability and resistance.

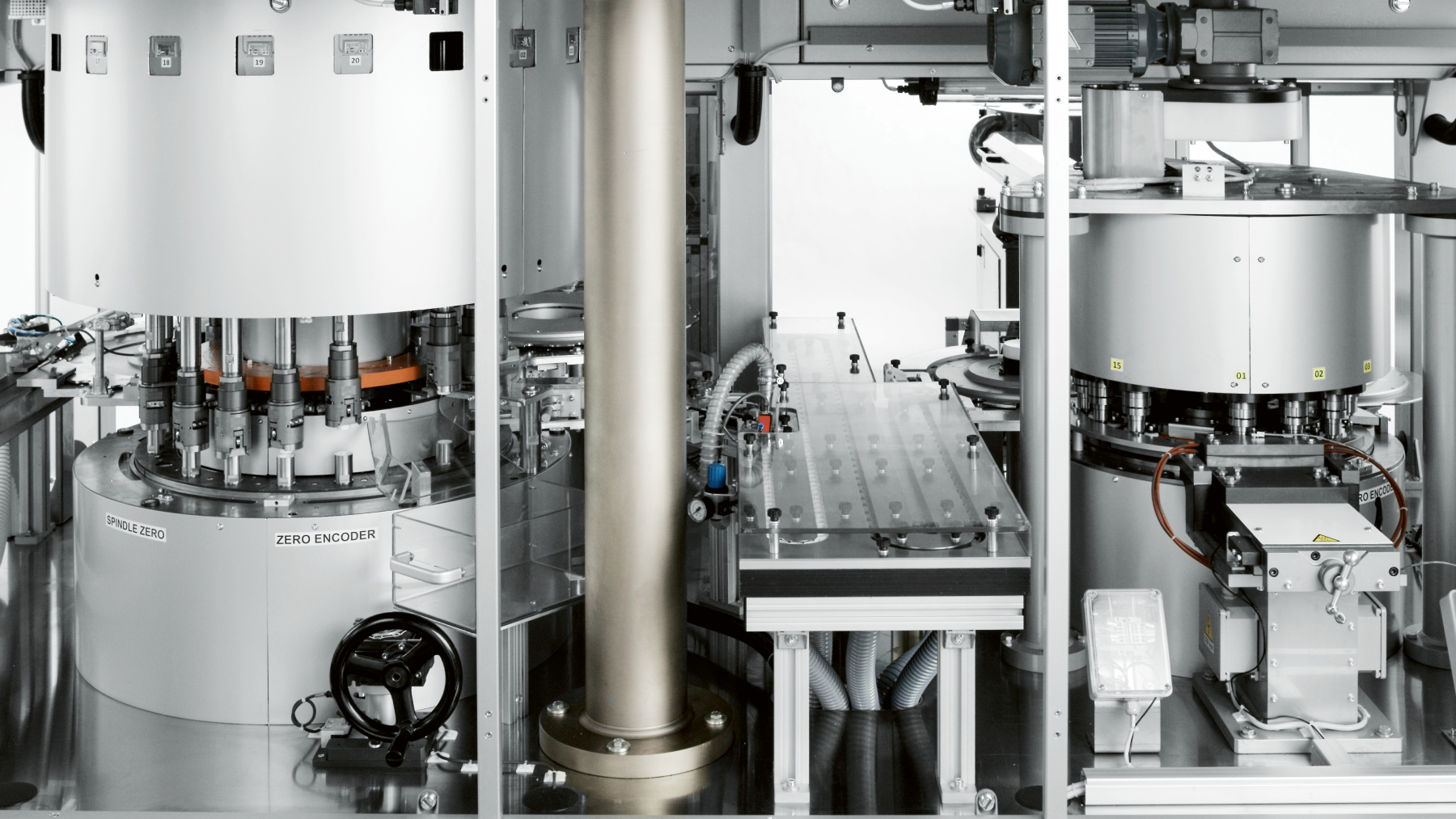

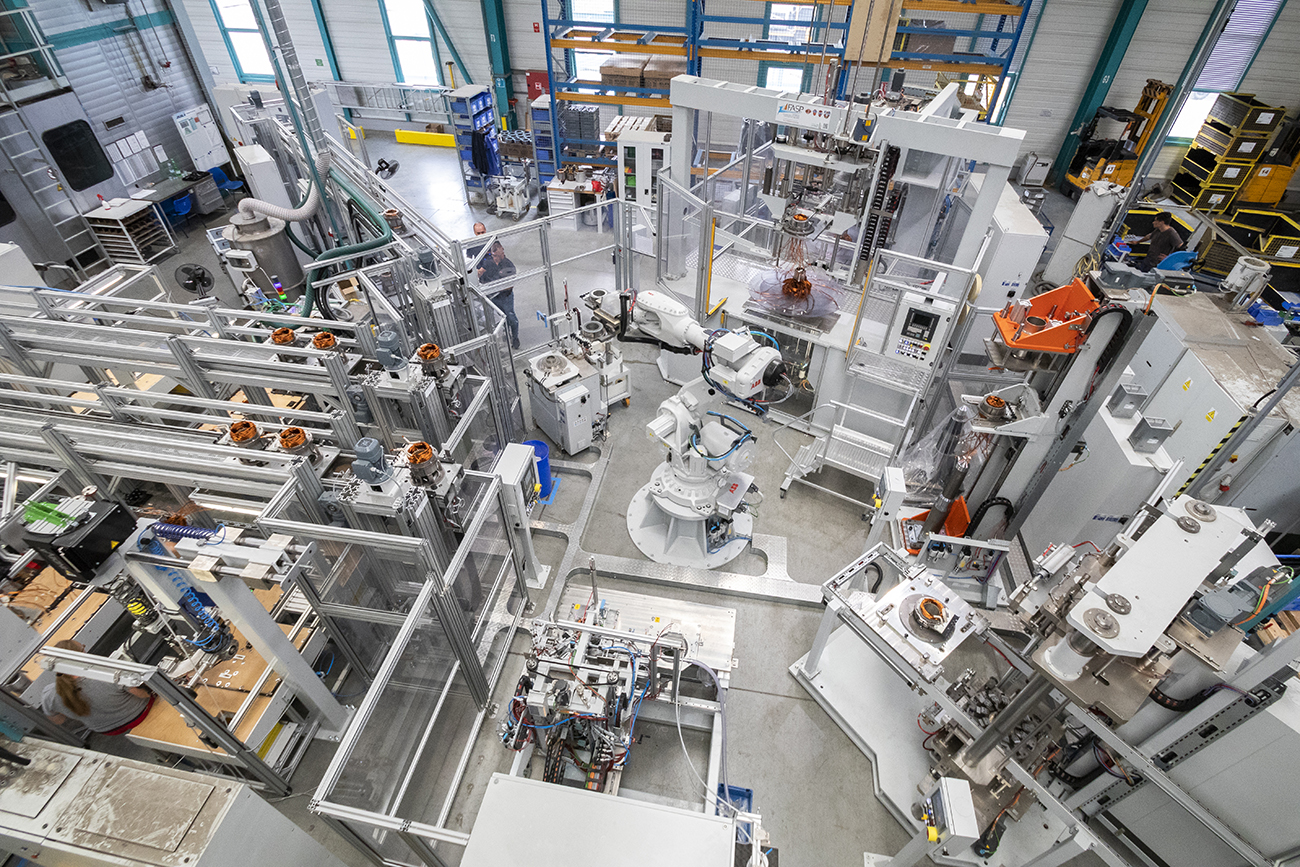

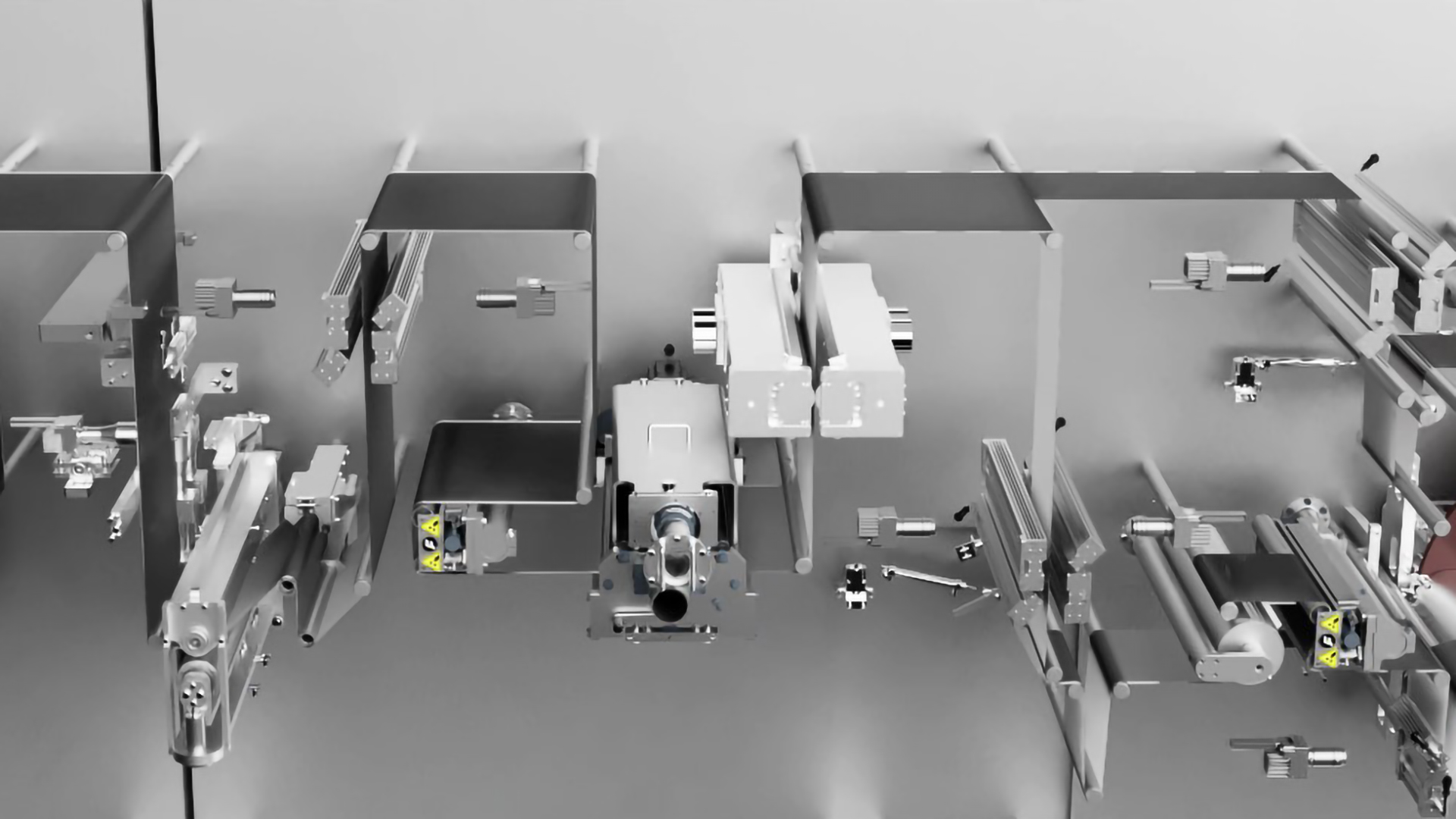

IMA AUTOMATION presents the widest range of tailored solutions to meet customers' requirements. From stand-alone machines to produce prototypes to complete automatic lines for brushless motor series production, for the processes of lamination staking, slot insulating, winding, wire-leads termination and electrical testing.

Power Tools

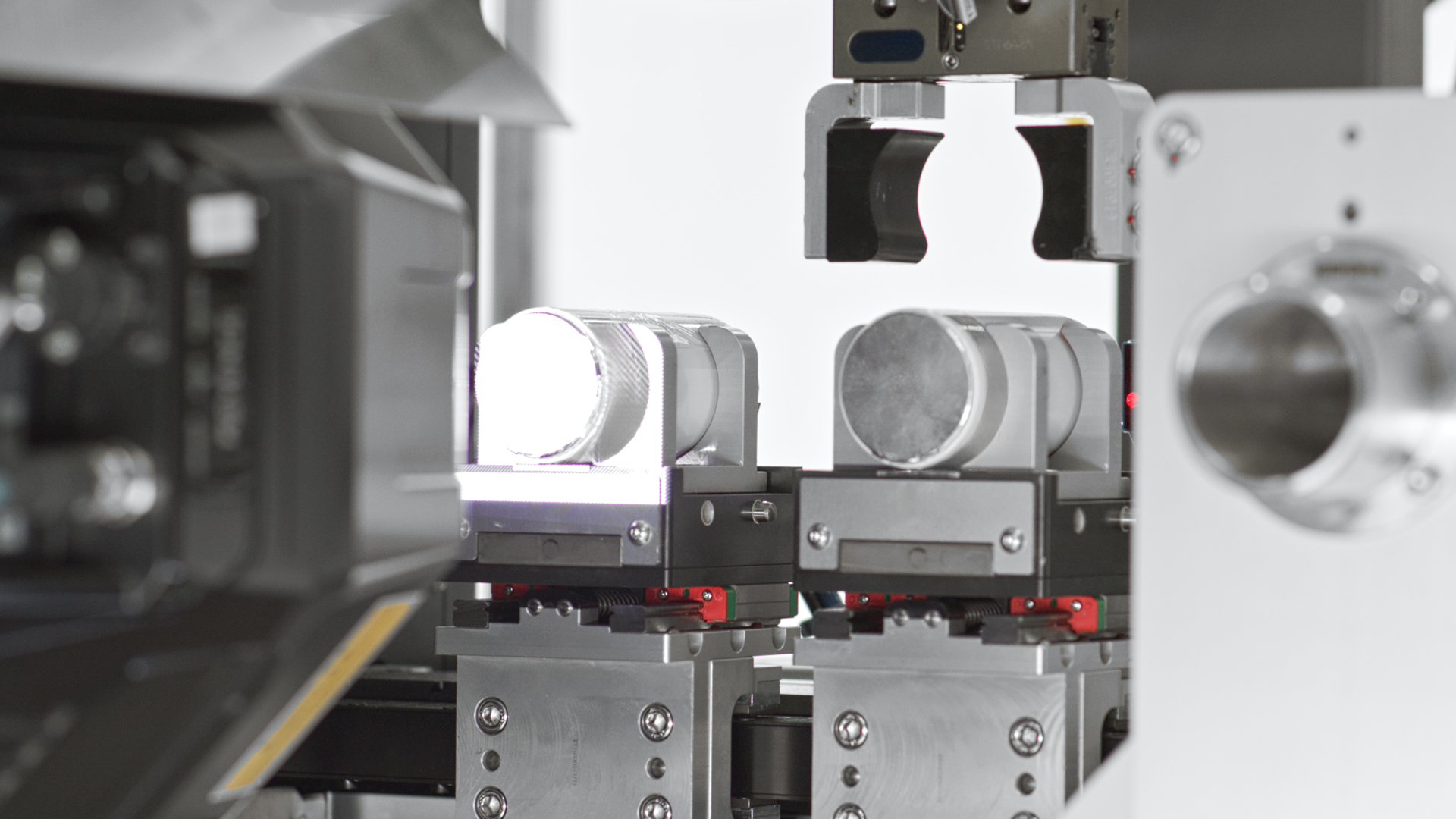

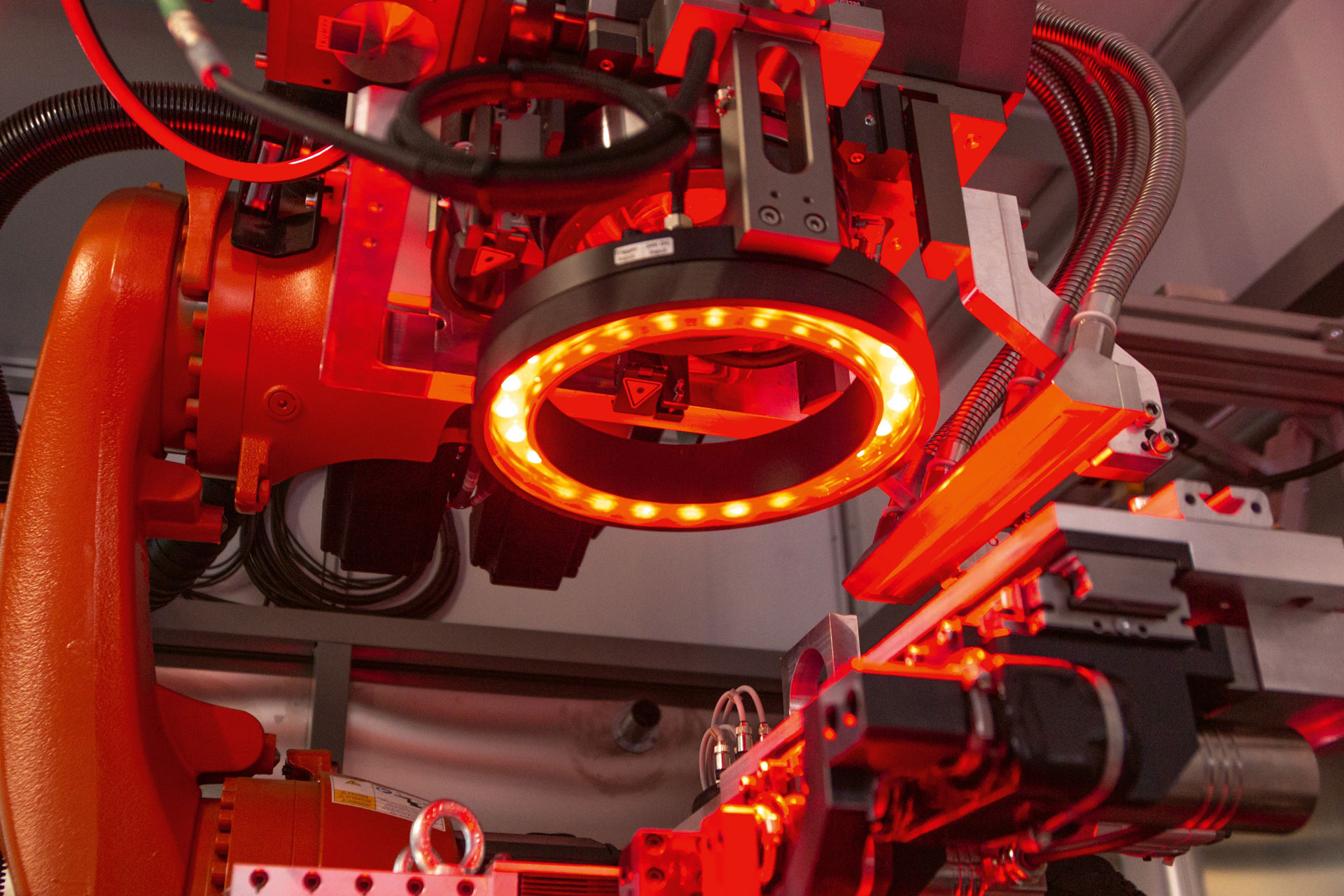

Our know-how and continuous innovation allow us to supply tailored solutions with high technological content to produce the latest generation electric motors for the power tools appliances, which are more and more efficient, compact and with reduced energy consumption.

Household Appliances

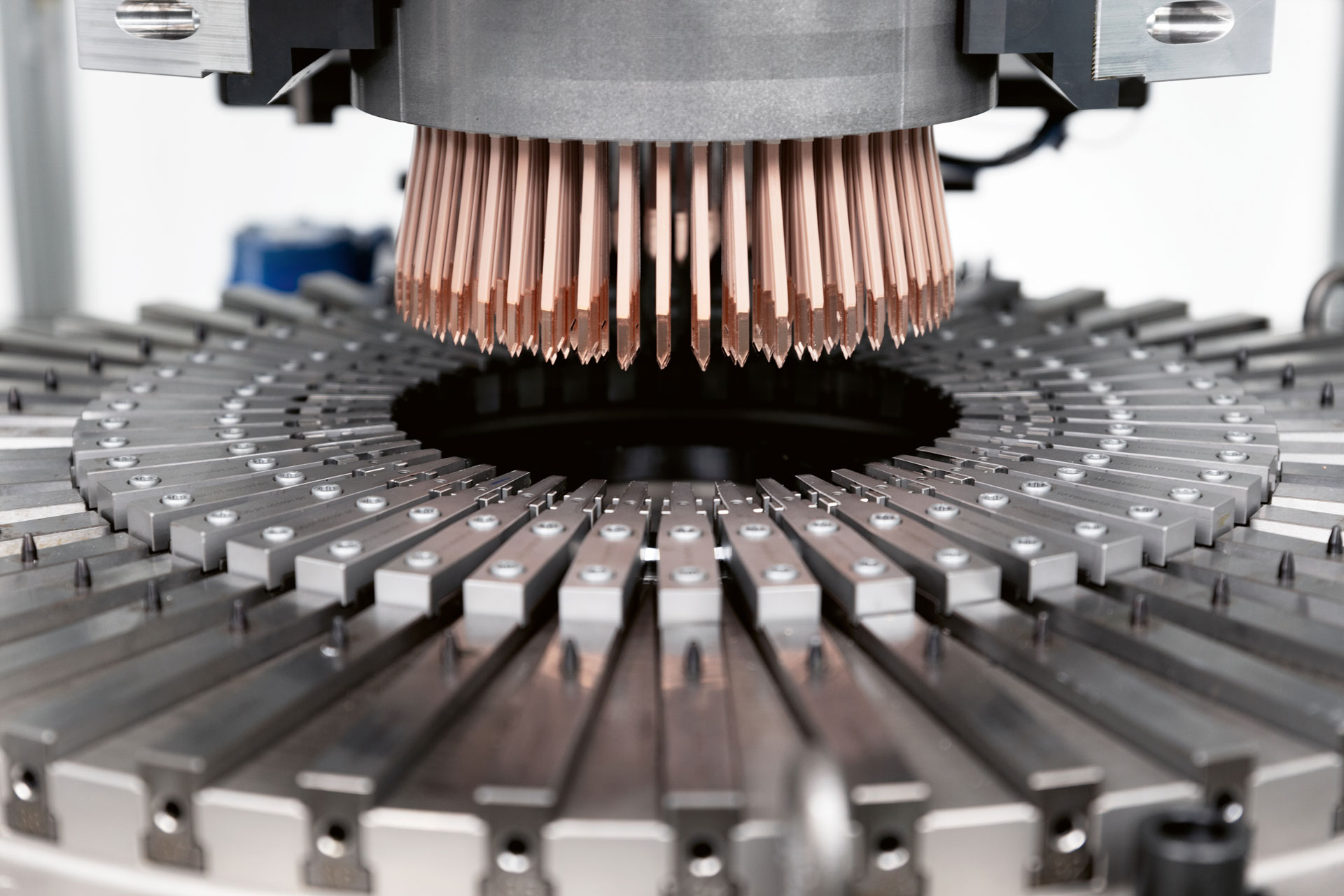

Electric motors have found large use in the household appliance industry and in our daily life. They’re present in very small or big appliances for the food preparation, the house cleaning and the body care. Our machines represent the technological excellence as regards brushless stators winding, being able to wind a high number of turns at hight speed and to guarantee maximum performance, efficiency, process repeatability, flexibility and reliability.

Vehicle Auxiliary Motors

Advanced

E-Motors

assembly from within

E-Motors

assembly from within

Technologies

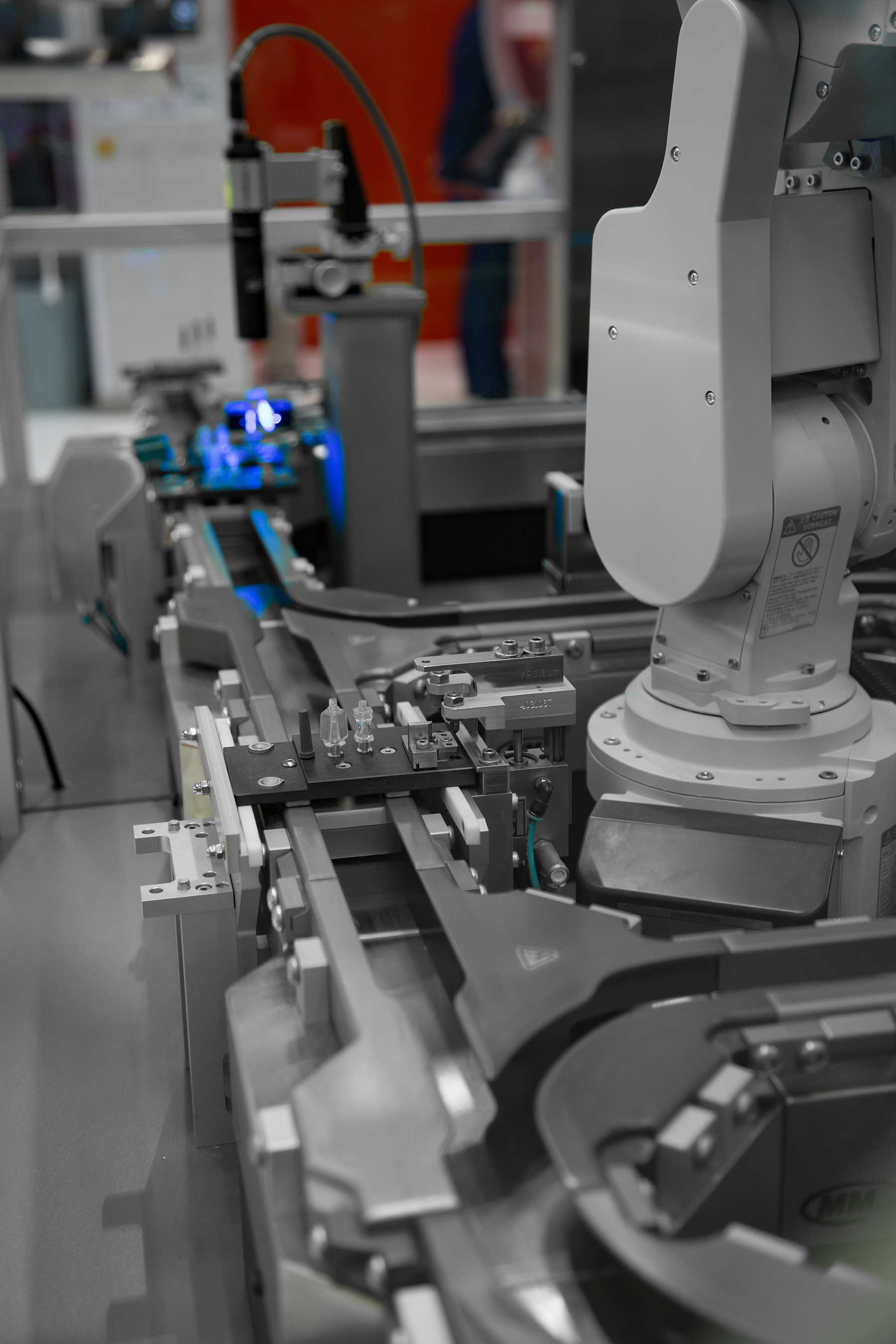

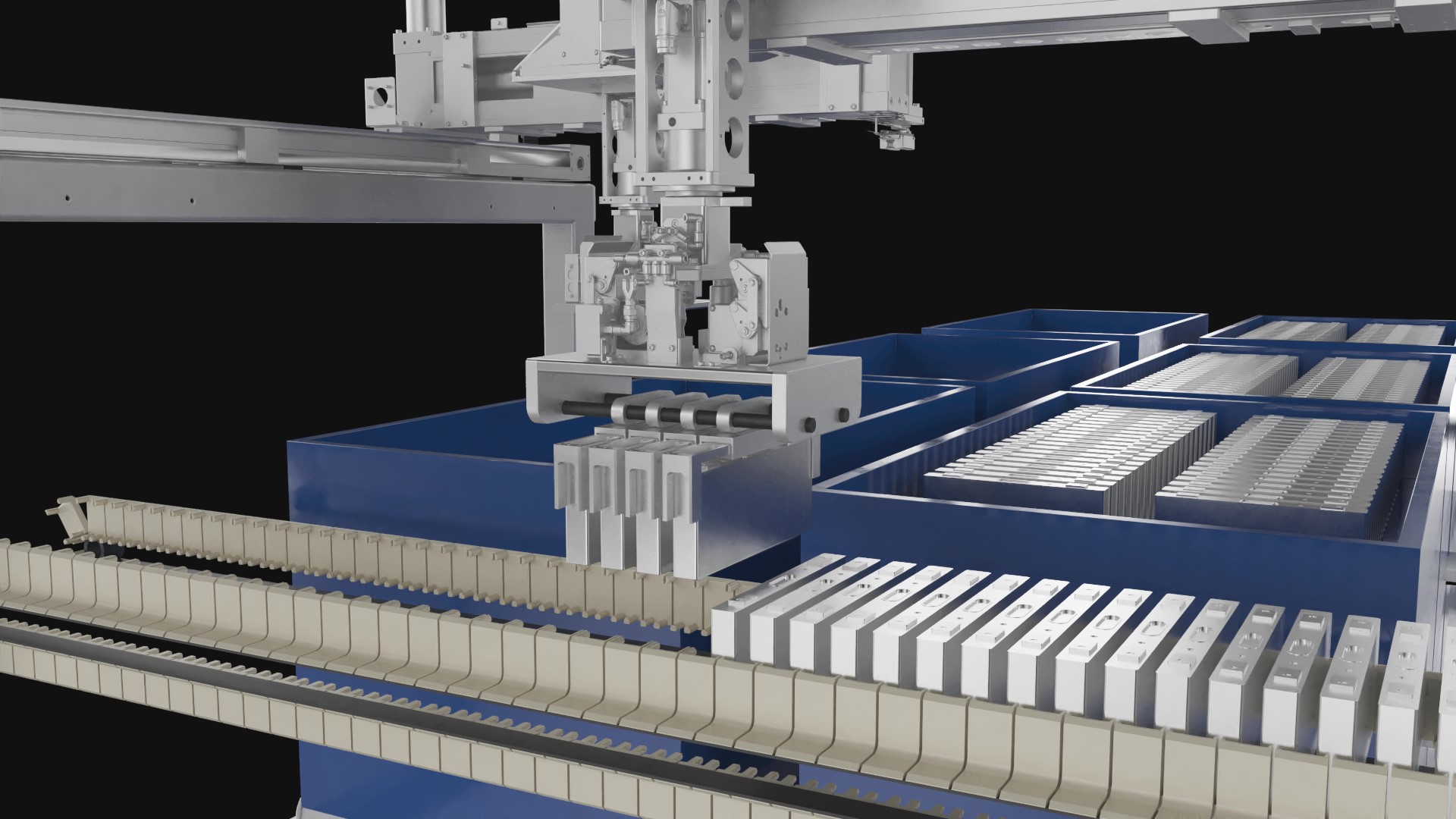

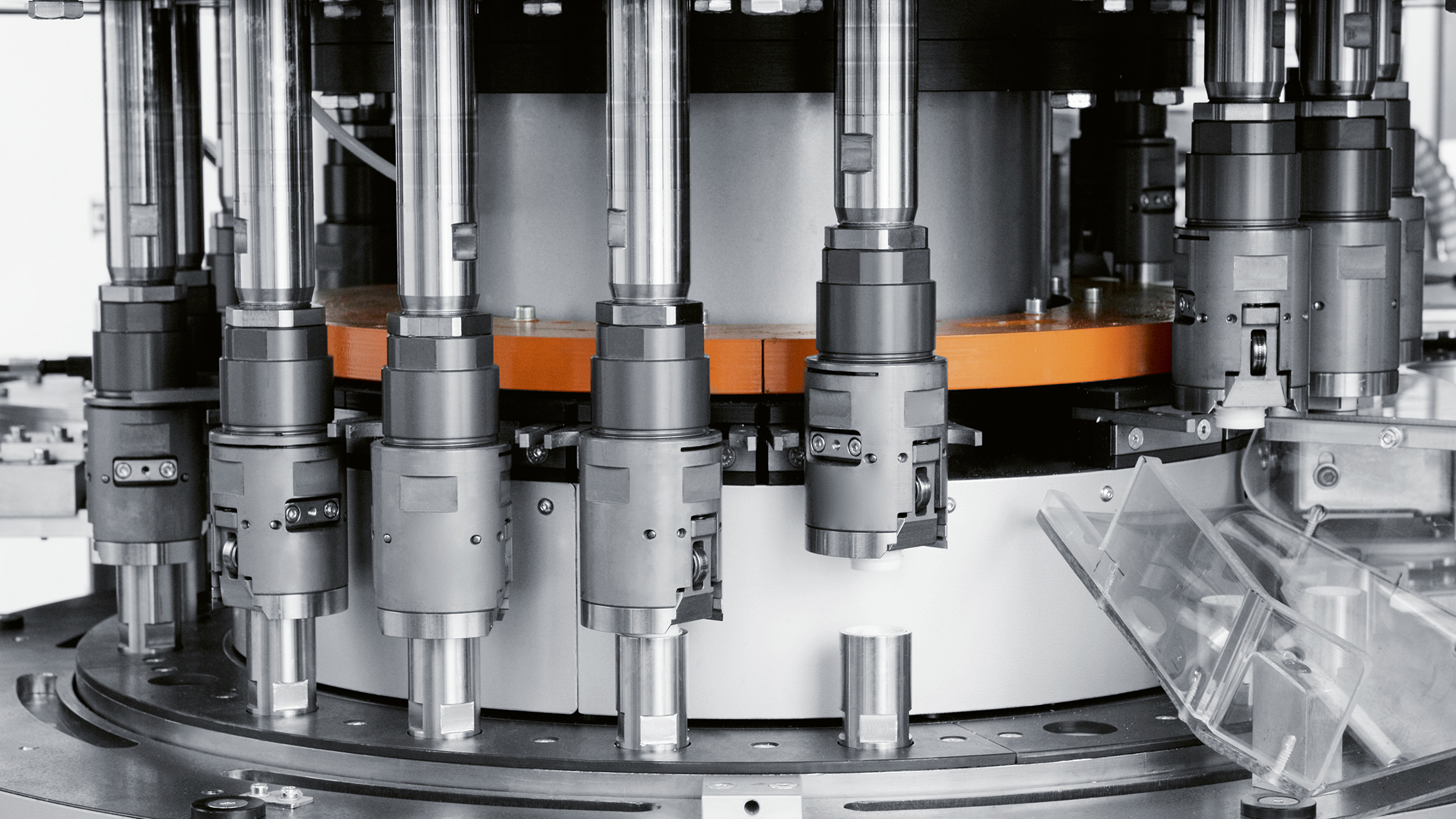

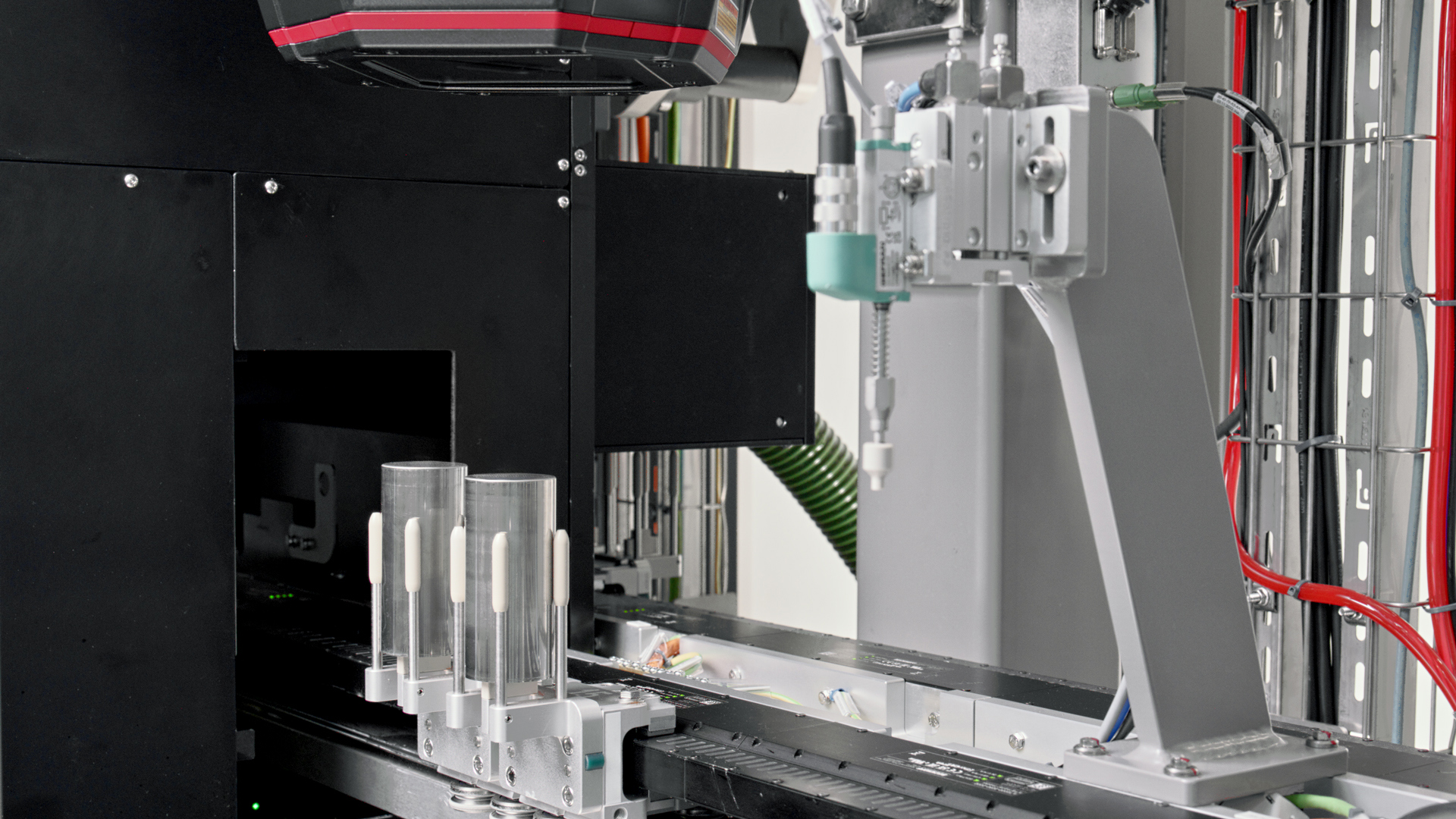

A wide complete range of continuous and indexing platforms, as well as demolding and robotized solutions, which cover all needs of caps & closures assembly.

Each assembly system consists of a platform that forms the basis for a made to measure solution to satisfy specific needs. Stations and assembly technologies are added in accordance with customer requirements.

Technologies

A wide complete range of continuous and indexing platforms, as well as demolding and robotized solutions, which cover all needs of caps & closures assembly.

Each assembly system consists of a platform that forms the basis for a made to measure solution to satisfy specific needs. Stations and assembly technologies are added in accordance with customer requirements.